Abstract

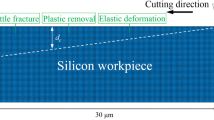

In this paper, the load-displacement curve of mono-crystalline silicon is first obtained by serials of nano-indentation experiments. Then, the material constitutive model of mono-crystalline silicon is developed. On this basis, a finite element method (FEM) model for the cutting process of mono-crystalline silicon is built and the critical brittle-ductile transition thickness is obtained by cutting simulations. Moreover, the fly-cut experiments on the ultra-precision diamond machine are performed to analyze the effect of cutting speeds on the brittle-ductile transition thicknesses, which are also used to validate the simulation results. Finally, by using extended element method, the mechanism of initiation and propagation of crack in the cutting process of mono-crystal silicon is studied and the effects of cut-induced cracks on the brittle-ductile transition of mono-crystalline silicon are deeply understood.

Similar content being viewed by others

References

Choi DH, Lee JR, Kang NR et al (2017) Study on ductile mode machining of single-crystal silicon by mechanical machining. Int J Mach Tools Manuf 113:1–9

Fang FZ, Zhang GX (2003) An experimental study of edge radius effect on cutting single crystal silicon. Int J Adv Manuf Technol 22(9–10):703–707

Durazo-Cardenas I, Shore P, Luo XC et al (2007) 3D characterisation of tool wear whilst diamond turning silicon. Wear 262(3–4):340–349

Mir A, Luo XC, Sun JN (2016) The investigation of influence of tool wear on ductile to brittle transition in single point diamond turning of silicon. Wear 364-365:233–243

Alao AR, Konneh M (2012) Surface finish prediction models for precision grinding of silicon. Int J Adv Manuf Technol 58(9–12):949–967

Pharr GM, Oliver WC, Clarke DR (1990) The mechanical behavior of silicon during small-scale indentation. J Electron Mater 19(9):881–887

Leung TP, Lee WB, Lu XM (1998) Diamond turning of silicon substrates in ductile-regime. J Mater Process Tech 73(1–3):42–48

Born DK, Goodman WA (1999) An empirical survey on the influence of machining parameters on tool wear in diamond turning of large single-crystal silicon optics. Precis Eng 25(4):247–257

Youna SW, Kang CG (2005) FEA study on nanodeformation behaviors of amorphous silicon and borosilicate considering tip geometry for pit array fabrication. Mat Sci Eng A 390:233–239

Shim S, Jang JI, Pharr GM (2008) Extraction of flow properties of single-crystal silicon carbide by nanoindentation and finite-element simulation. Acta Mater 56(15):3824–3832

Zhao QL, Chen MJ, Liang YC et al (2002) Effects of diamond cutting tools rake angle and rounded cutting edge radius on the machined single crystal silicon surface quality. Chin J Mech Eng-En 38(12):54–59

Yan JW, Zhao HW, Kuriyagawa T (2009) Effects of tool edge radius on ductile machining of silicon: an investigation by FEM. Semicond Sci Tech 24(7):075018–075029

Ajjarapu SK, Patten JA, Cherukuri H et al (2004) Numerical simulations of ductile regime machining of silicon nitride using the Drucker-Prager material model. P I Mech Eng C-J Mec 218(6):577–582

Mir A, Luo XC, Siddiq A (2017) Smooth particle hydrodynamics study of surface defect machining for diamond turning of silicon. Int J Adv Manuf Technol 88:2461–2476

Goel S, Luo XC, Comley P et al (2013) Brittle–ductile transition during diamond turning of single crystal silicon carbide. Int J Mach Tools Manuf 65(2):15–21

Chavoshi SZ, Goel S, Luo XC (2016) Molecular dynamics simulation investigation on the plastic flow behaviour of silicon during nanometric cutting. Modelling Simul Mater Sci Eng 24(5):1–8

Zhang ZG, Fang FZ, Hu XT et al (2009) Three-dimensional molecular dynamics modeling of nanocutting. J Vac Sci Technol B 27(3):1340–1344

Pei QX, Lu C, Fang FZ et al (2011) Molecular dynamics simulation of nanometric cutting process. Int J Nanosci 2011(5):633–638

Wu H, Fang FZ, Pei QX (2006) Study on nanometric cutting mechanism and burr formation using molecular dynamics simulation. Int J Nanosci 5:547–551

Fang FZ, Wu H, Zhou W et al (2007) A study on mechanism of nano-cutting single crystal silicon. J Mater Process Tech 184(1):407–410

Pei QX, Lu C, Fang FZ et al (2006) Nanometric cutting of copper: a molecular dynamics study. Comput Mater Sci 37(4):434–441

Drucker DC, Prager W (1952) Soil mechanics and plastic analysis or limit design. Quart Appl Math 10(2):157–165

Acknowledgements

The authors would like to thank the National Natural Science Foundation of China (Grant No. 51475108 and Grant No. 51675352).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, H., Xie, W., Sun, Y. et al. Investigations on brittle-ductile cutting transition and crack formation in diamond cutting of mono-crystalline silicon. Int J Adv Manuf Technol 95, 317–326 (2018). https://doi.org/10.1007/s00170-017-1108-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1108-1