Abstract

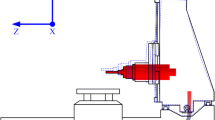

To improve the spindle thermal error prediction accuracy, the least absolute shrinkage and selection operator (LASSO) is used to directly select the temperature-sensitive point subset to guarantee the prediction performance of the thermal error model built by least squares support vector machines (LS-SVM). Taking a horizontal machining center as a test stand, the thermal error experiments with different spindle speed states are carried out. Then the temperature-sensitive points are selected using LASSO. The number of temperature-sensitive points is reduced from 20 to 7. Afterward, the thermal error model is designed by LS-SVM. The prediction performance and generalization performance of the thermal error model are compared with another two thermal error models using gray model (GM) and multiple linear regression (MLR), respectively. The comparison results indicate that the thermal error model derived from LS-SVM shows better prediction performance and generalization performance than those derived from GM and MLR with the highest prediction accuracy increasing about 74.6 and 54.3%, respectively. Thus, the feasibility and effectiveness of the proposed spindle thermal error robust modeling method are validated.

Similar content being viewed by others

References

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools—a review: part II: thermal errors. Int J Mach Tools Manuf 40(9):1257–1284

Mayr J, Jedrzejewski J, Uhlmann E, Alkan Donmez M, Knapp W, Hartig F, Wendt K, Moriwaki T, Shore P, Schmitt R (2012) Thermal issues in machine tools. CIRP Ann Manuf Technol 61(2):771–791

Li Y, Zhao WH, Lan SH, Ni J, Wu WW, Lu BH (2015) A review on spindle thermal error compensation in machine tools. Int J Mach Tools Manuf 95:20–38

Cao HR, Zhang XW, Chen XF (2016) The concept and progress of intelligent spindles: a review. Int J Mach Tools Manuf 112:21–52

Abdulshahed AM, Longstall AP, Fletcher S (2015) The application of ANFIS prediction models for thermal error compensation on CNC machine tools. Appl Soft Comput 27:158–168

Tan F, Yin GF, Yin Q, Dong GH, Wang L (2016) CNC machine tool thermal error modeling based on GM-LS-SVM hierarchical model. J Central South Univ (Sci and Technol) 12:4028–4034 (in Chinese)

Sun LJ, Ren MJ, Hong HB, Yin YH (2017) Thermal error reduction based on thermodynamics structure optimization method for an ultra-precision machine tool. Int J Adv Manuf Technol 88(5–8):1267–1277

Creighton E, Honegger A, Tulsian A, Mukhopadhyaye D (2010) Analysis of thermal errors in a high-speed micro-milling spindle. Int J Mach Tools Manuf 50(4):386–393

Wang LP, Wang HT, Li TM, Li FC (2015) A hybrid thermal error modeling method of heavy machine tools in z-axis. Int J Adv Manuf Technol 80(1–4):389–400

Holman JP (2010) Heat transfer. McGraw-Hill

Liang RJ, Ye WH, Zhang HY, Yang QF (2012) The thermal error optimization models for CNC machine tools. Int J Adv Manuf Technol 63(9–12):1167–1176

Guo QJ, Yang JG, Wu H (2010) Application of ACO-BPN to thermal error modeling of NC machine tool. Int J Adv Manuf Technol 50(5):667–675

Guo QJ, Xu RF, Yang TY, He L, Cheng X, Li ZY, Yang JG (2016) Application of GRAM and AFSACA-BPN to thermal error optimization modeling of CNC machine tools. Int J Adv Manuf Technol 83(5–8):995–1002

Ma C, Zhao L, Mei XS, Shi H, Yang J (2017) Thermal error compensation of high-speed spindle system based on a modified BP neural network. Int J Adv Manuf Technol 89(9–12):3071–3085

Miao EM, Liu Y, Liu H, Gao ZH, Li W (2015) Study on the effects of changes in temperature-sensitive points on thermal error compensation model for CNC machine tool. Int J Adv Manuf Technol 97:50–59

Wang HT, Wang LP, Li TM, Han J (2013) Thermal sensor selection for the thermal error modeling of machine tool based on the fuzzy clustering method. Int J Adv Manuf Technol 69(1):121–126

Cheng Q, Qi Z, Zhang GJ, Zhao YS, Sun BW, Gu PH (2016) Robust modelling and prediction of thermally induced positional error based on grey rough set theory and neural networks. Int J Adv Manuf Technol 83(5):1–12

Tibshirani R (1996) Regression shrinkage and selection via the lasso. J. R. Statist. Soc. B 58(1):267–288

Friedman J, Hastie T, Tibshirani R (2010) Regularization paths for generalized linear models via coordinate descent. J Statist Soft 33(1):1–22

Zou H, Hastie T (2005) Regularization and variable selection via the elastic net. J R Statist Soc B 67(2):301–320

Suykens J A K, Van Gestel T, De Brabanter J (2002) Least squares support vector machines. World Scientific

Liu SF, Dang YG, Fang ZG (2010) Gray system theory and its application. Science Press, Beijing

Zhang Y, Yang JG, Jiang H (2012) Machine tool thermal error modeling and prediction by grey neural network. Int J Adv Manuf Technol 59(9):1065–1072

ISO 230-3 (2007) Test code for machine tools part 3: determination of thermal effects. ISO copyright office, Geneva

Geisser S (1993) Predictive inference. CRC press

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, F., Yin, M., Wang, L. et al. Spindle thermal error robust modeling using LASSO and LS-SVM. Int J Adv Manuf Technol 94, 2861–2874 (2018). https://doi.org/10.1007/s00170-017-1096-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1096-1