Abstract

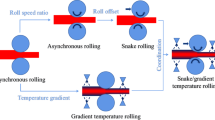

The AC (alternating current) servo axial-infeed incremental warm rolling equipment was studied in this paper on the basis of the integration of process and equipment. Firstly, the details of each subsystem are discussed to demonstrate the features of the novel rolling equipment. Next, the performance of the AC servo axial-infeed incremental warm rolling equipment is investigated through the experiments. The whole rolling process of spline shaft lasted about 2 min in the rolling equipment, which is greatly reduced compared with traditional processes. The testing results of rotational speed show that the root mean square error (RMSE) values of speed are less than 5%, which indicate that the rolling equipment can ensure the precision of rotational speed through servo system. Finally, the simulated production of spline shafts was carried out on the rolling equipment. According to the dimensional measurement results of the formed spline shaft, the percent of pass is 80% for the simulated production. In addition, the microstructure observation and the hardness measurement proved that the formed spline shafts possess an excellent performance.

Similar content being viewed by others

References

Zhang DW, Li YT, Fu JH (2007) Mechanics analysis on precise forming process of external spline cold rolling. Chin J Mech Eng 20:54–58

Li YY, Zhao SD, Fan SQ, Yan GH (2013) Study on the material characteristic and process parameters of the open-die warm extrusion process of spline shaft with 42CrMo steel. J Alloys Compd 571:12–20

Altinbalik T, Ayer Ö (2008) A theoretical and experimental study for forward extrusion of clover sections. Mater Des 29:1182–1189

Simoneau A, Ng E, Elbestawi MA (2007) Modeling the effects of microstructure in metal cutting. Int J Mach Tool Manu 47:368–375

Wang ZK, Zhang Q (2008) Numerical simulation of involutes spline shaft in cold rolling forming. J Cent South Univ S2:278–283

Zhang DW, Li YT, Fu JH (2008) Tooth curves and entire contact area in process of spline cold rolling. Chin J Mech Eng 21:94–97

Zhang DW, Zhao SD (2014) New method for forming shaft having thread and spline by rolling with round dies. Int J Adv Manuf Technol 70:1455–1462

Cui FK, Li Y, Zhou YW, Yang JX, Zhou ZL, Li CM (2006) The design and simulation of roller for machining involute spline. IEEE Xplore. https://doi.org/10.1109/ICMA.2006.257470

Cui FK, Wang XQ, Zhang FS, Xu HY, Quan JH, Li Y (2013) Metal flowing of involute spline cold roll–beating forming. Chin J Mech Eng 26:1056–1062

Cui MC, Zhao SD, Zhang DW, Chen C, Fan SQ, Li YY (2017) Deformation mechanism and performance improvement of spline shaft with 42CrMo steel by axial-infeed incremental rolling process. Int J Adv Manuf Technol 88:2621–2630

Cui MC, Zhao SD, Chen C, Zhang DW, Li YY (2017) Finite element modeling and analysis for the integration–rolling–extrusion process of spline shaft. Adv Mech Eng 9:1–11

Cui MC, Zhao SD, Chen C, Zhang DW, Li YY (2016) Process parameter determination of the axial-pushed incremental rolling process of spline shaft. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-016-9604-2

Cui MC, Zhao SD, Zhang DW, Chen C, Li YY (2016) Finite element analysis on axial-pushed incremental warm rolling process of spline shaft with 42CrMo steel and relevant improvement. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-016-9566-4

Cui MC, Zhao SD, Chen C, Zhang DW, Li JX, Li YY (2017) Study on warm forming effects of the axial-pushed incremental rolling process of spline shaft with 42CrMo steel. P I Mech Eng E-J Pro. https://doi.org/10.1177/0954408917727214

Fu XB, Wang BY, Zhu XX, Tang XF, Ji HC (2016) Numerical and experimental investigations on large-diameter gear rolling with local induction heating process. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-016-9713-y

Zhang DW, Zhao SD, Wu SB, Zhang Q, Fan SQ, Li JX (2015) Phase characteristic between dies before rolling for thread and spline synchronous rolling process. Int J Adv Manuf Technol 81:513–528

Huang ZH, Fu PF (2001) Solution to the bulging problem in the open-die cold extrusion of a spline shaft and relevant photo plastic theoretical study. J Mater Process Technol 114:185–188

Li YY, Zhao SD, Zhao YQ, Liu C (2014) Analysis and experiment on the effect of system parameters on the axial-infeed rolling forming process of spline shaft. J Mech Eng 50:50–56

Funding

The authors gratefully acknowledge the contribution of the subjects: the National Natural Science Foundation of China for key Program (Grant No. 51335009), Shaanxi Province Natural Science Foundation of China (Grant No. 2014JQ7273), and State Key Laboratory for Mechanical Behavior of Materials (Grant No. 1991DA105206).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, H., Cui, MC., Zhang, Y. et al. Performance of AC servo axial-infeed incremental warm rolling equipment and simulated production of spline shafts. Int J Adv Manuf Technol 94, 2089–2097 (2018). https://doi.org/10.1007/s00170-017-1003-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1003-9