Abstract

The central deformation extent of the thick plate can be improved and the approaching uniform deformation will be realized by the snake/gradient temperature rolling (SGTR). At present, the existing rolling force analytical models cannot be directly used for SGTR because of the great difference with the synchronous rolling. The rolling force model should be established so as to meet the production demand of the SGTR with different roll diameters. The thick plate is divided into three layers according to the numerical results of the short-term ultra-fast cooling for the thick plate. The deformation region is simplified into different zones and layers according to the temperature gradient and neutral point position. The traditional von Mises yield criterion was optimized by the introduced coefficients c1 and c2 according to the slip line field theory to correct the deviation caused by the uniform and shear stress assumption. The specific pressure equation is established by the slab method. The deformation region with different composition cases is analyzed, and the rolling force and torque analytical models are established according to the boundary conditions on this basis. The short-term ultra-fast cooling and rolling process were simulated by ANSYS software. The deformation resistance gradient produced by short-term ultra-fast cooling and roll diameter ratio are the main factors to affect the rolling force, while the roll offset has little effect on the rolling force because of its small proportion in the deformation region. The position of neutral points not only affects the rolling torque, but also changes its direction in certain conditions. The model precision was analyzed, and the rolling force calculated by the established analytic model is in good agreement with the numerical method, which serves as a theoretical basis for the rolling mill design and process parameter setting.

Similar content being viewed by others

References

Ding H, Zhu C, Song C, Qian D (2017) Effect of the quenching residual stress on ductile fracture behavior of pre-stretched aluminum alloy plates. J Braz Soc Mech Sci 39(6):1–9. https://doi.org/10.1007/s40430-017-0713-0

Maji P, Ghosh SK, Nath RK, Karmakar R (2020) Microstructural, mechanical and wear characteristics of aluminum matrix composites fabricated by friction stir processing. J Braz Soc Mech Sci 42(4):1–24. https://doi.org/10.1007/s40430-020-02279-5

Zhang X, Hashimoto T, Lindsay J, Zhou X (2016) Investigation of the de-alloying behaviour of θ-phase (Al2Cu) in AA2024-T351 aluminium alloy. Corros Sci 108:85–93. https://doi.org/10.1016/j.corsci.2016.03.003

Petra L, Marián B, Milkovi O, Vojtko M, Dragoek L (2015) Influence of heat treatment on properties of EN AW 6082 aluminium alloy. Development 21(1):4057–4067. https://doi.org/10.12776/ams.v21i1.553

Hao PJ, He AR, Sun WQ (2018) Formation mechanism and control methods of inhomogeneous deformation during hot rough rolling of aluminum alloy plate. Arch Civ Mech Eng 18(1):245–255. https://doi.org/10.1016/j.acme.2017.07.004

Zhang XM, Han NM, Liu SD et al (2010) Inhomogeneity of texture, tensile property and fracture toughness of 7050 aluminum alloy thick plate. Chin J Nonferrous Metals 20(02):202–208. https://doi.org/10.19476/j.ysxb.1004.0609.2010.02.006

Chen Y, Gao QM, Tian N (2011) Effect of asynchronous rolling on deforming texture in Al alloy 6111. Adv Mater Res 299-300:127–130. https://doi.org/10.4028/www.scientific.net/AMR.299-300.127

Zhang T, Wu YX, Gong H, Zheng XZ, Jiang SS (2014) Effects of rolling parameters of snake hot rolling on strain distribution of aluminum alloy 7075. Trans Nonferrous Metal Soc 24(7):2150–2156. https://doi.org/10.1016/S1003-6326(14)63326-4

Ling L, Tang J, Liu W, Zhang X, Deng Y (2017) Numerical simulation evolution of shear strain and crystallographic textures during snake rolling of Al-Mg-Si alloy plate. J Cent South Univ 48(9):2279-2287. https://doi.org/10.11817/j.issn.1672-7207.2017.09.004

Yang J, Li S, Liu J, Zhang X (2017) Finite element analysis of bending behavior and strain heterogeneity in snake rolling of AA7050 plates using a hyperbolic sine-type constitutive law. J Mater Process Technol 240:274–283. https://doi.org/10.1016/j.jmatprotec.2016.10.009

Jiang LY, Zhao CJ, Yuan G, Shi JH, Wang GD (2016) Thicker steel plate shape changing law and control method during snake rolling process. Metall Res Technol 113(2):309. https://doi.org/10.1051/metal/2016007

Ding JG, Zhao Z, Jiao ZJ, Wang J (2016) Central infiltrated performance of deformation in ultra-heavy plate rolling with large deformation resistance gradient. Appl Therm Eng 98:29–38. https://doi.org/10.1016/j.applthermaleng.2015.12.021

Ye LY, Huang XY, Fan ST, Zhang Y, Deng YL (2018) Effects of differential temperature rolling on 7050 Aluminum alloy thick plate. J Cent South Univ 49(09):2160–2167. https://doi.org/10.11817/j.issn.1672-7207.2018.09.007

Yu W, Li GS, Cai QW (2015) Effect of a novel gradient temperature rolling process on deformation, microstructure and mechanical properties of ultra-heavy plate. J Mater Process Technol 217:317–326. https://doi.org/10.1016/j.jmatprotec.2014.11.011

Li GS, Yu W, Cai QW (2015) Investigation of the evolution of central defects in ultra-Heavy plate rolled using gradient temperature process. Metall Mater Trans B Process Metall Mater Process Sci 46(2):831–840. https://doi.org/10.1007/s11663-014-0235-4

Li GS, Yu W, Cai QW, He ZY (2017) Effect of gradient temperature rolling (GTR) and cooling on microstructure and properties of E40-grade heavy plate. Arch Civ Mech Eng 17(1):121–131. https://doi.org/10.1016/j.acme.2016.09.004

Jiang LY, Zhen T, Yuan G, Huang JB, Wei YY, Li H, Wang P (2020) The mechanical parameters modeling of heavy steel plate snake/gradient temperature rolling with the same roll diameters. Metall Res Technol 117(3):301. https://doi.org/10.1051/metal/2020019

Zhang SH, Zhao DW, Gao CR, Wang GD (2012) Analysis of asymmetrical sheet rolling by slab method. Int J Mech Sci 65(1):168–176. https://doi.org/10.1016/j.ijmecsci.2012.09.015

Wang HY, Li X, Sun J, Wang ZH, Zhao DW, Zhang DH (2016) Analysis of sandwich rolling with two different thicknesses outer layers based on slab method. Int J Mech Sci 106:194–208. https://doi.org/10.1016/j.ijmecsci.2015.12.021

Qwamizadeh M, Kadkhodaei M, Salimi M (2014) Asymmetrical rolling analysis of bonded two-layer sheets and evaluation of outgoing curvature. Int J Adv Manuf Technol 73(1-4):521–533. https://doi.org/10.1007/s00170-014-5825-4

Afrouz F, Parvizi A (2015) An analytical model of asymmetric rolling of unbounded Clad sheets with shear effects. J Manuf Process 20(OCT.PT.1):162–171. https://doi.org/10.1016/j.jmapro.2015.08.007

Parvizi A, Afrouz F (2016) Slab analysis of asymmetrical clad sheet bonded before rolling process. Int J Adv Manuf Technol 87(1-4):137–150. https://doi.org/10.1007/s00170-016-8419-5

Jiang LY, Meng QC, Zhao CJ, Wang SX, Liu YW (2018) The Analytic study on the heavy steel plate snake rolling with the same roll diameters. Math Probl Eng 2018(6):1–11. https://doi.org/10.1155/2018/7807580

Meng QC, Jiang LY, Ma LF, Lei JY (2019) The analytic study on the heavy steel plate snake rolling with the different roll diameters. Metall Res Technol 116(4):402. https://doi.org/10.1051/metal/2018119

Jiang LY, Yuan G, Wu D et al (2015) Calculation model of temperature field and its deviation analysis for hot rolled strip. J Northeast Univ 36(7):937–941. https://doi.org/10.3969/j.issn.1005-3026.2015.07.006

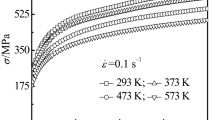

Yi YP, Yang JH, Lin YC (2007) Flow stress constitutive equation of 7050 aluminum alloy during hot compression. J Mater Eng 17:519–522. https://doi.org/10.1016/S1003-6326(07)60126-5

Salimi M, Sassani F (2002) Modified slab analysis of asymmetrical plate rolling. Int J Mech Sci 44(9):1999–2023. https://doi.org/10.1016/S0020-7403(02)00043-7

Availability of data and materials

Data and materials will be available upon request.

Funding

Research Program supported by the National Natural Science Foundation of China (No.: 51804206).

Author information

Authors and Affiliations

Contributions

Lianyun Jiang: conceptualization; writing—original draft preparation; visualization; project administration

Tao Zhen: writing—original draft preparation; visualization

Jinbo Huang: writing—review and editing; supervision

Yaoyu Wei: writing—review and editing, supervision

Heng Li: writing—review and editing; supervision

Lifeng Ma: writing—review and editing, supervision

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Ly., Zhen, T., Huang, Jb. et al. Calculation and analysis of rolling force during aluminum alloy thick plate snake/gradient temperature rolling with different roll diameters. Int J Adv Manuf Technol 115, 3453–3465 (2021). https://doi.org/10.1007/s00170-021-07244-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07244-7