Abstract

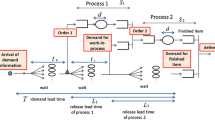

This paper attempts to propose a new multi-stage production-inventory system with and without lead times via an optimal control model. The proposed optimal control model for lead times contains some delays in the state variables. The considered dynamical system is a multi-stage production-inventory one which obeys a linear quadratic optimal control model with time delays in the states. Production lead times can be considered as required time for production. In the proposed system, the inventories of stocks are considered as state variables while the demand and ordering levels are control variables. In the proposed multi-stage system, returned items from one stock to the previous one is allowed with recycling. The exact solution of non-delay model along with the approximate solution of delayed system are obtained and compared in a real case study in granular polymer industry which the products are 3D panels and expanded polystyrene (EPS) blocks.

Similar content being viewed by others

References

Abdelghani B, Hedjar R, Tadj L (2016) Production planning in a three-stock reverse-logistics system with deteriorating items under a periodic review policy. J Ind Manag Optim 12.3:1075–1089

Bandaly D, Satir A, Shanker L (2016) Impact of lead time variability in supply chain risk management. Int J Prod Econ 180:88–100

Benjaafar S, ElHafsi M, Lee C-Y, Zhou W (2011) Technical note: optimal control of an assembly system with multiple stages and multiple demand classes. Oper Res 59(2):522–529

Csik A, Gy T, Horvath TL, Foldesi P (2010) An approximate analytic solution of the inventory balance delay differential equation. Acta Technica Jaurinensis 3.3:231–256

Effati S, Pakdaman M (2013) Optimal control problem via neural networks. Neural Comput & Applic 23(7-8):2093–2100

Glock CH, Jaber MY (2013) A multi-stage production-inventory model with learning and forgetting effects, rework and scrap. Comput Ind Eng 64(2):708–720

Heydari J, Zaabi-Ahmadi P, Choi T-M (2016) Coordinating supply chains with stochastic demand by crashing lead times. Comput Oper Res http://doi.org/https://doi.org/10.1016/j.cor.2016.10.009

Keller AA (2010) Generalized delay differential equations to economic dynamics and control. American-Math 10:278–286

Kirk DE (2012) Optimal control theory: an introduction. Courier Corporation

Kulkarni V, Yan K (2012) Production-inventory systems in stochastic environment and stochastic lead times. Queueing Syst 70(3):207–231

Le Thi HA, Tran DQ (2014) Optimizing a multi-stage production/inventory system by dc programming based approaches. Comput Optim Appl 57(2):441–468

Liberopoulos G, Dallery Y (2003) Comparative modelling of multi-stage production-inventory control policies with lot sizing. Int J Prod Res 41(6):1273–1298

Mezghiche A, Moula M, Tadj L (2015) Model predictive control of a forecasting production system with deteriorating items. International Journal of Operations Research and Information Systems (IJORIS) 6(4):19–37

Novotna V (2015) Numerical solution of the inventory balance delay differential equation. Int J Eng Business Manag 7(7):1–9

Pakdaman M, Effati S (2016) Approximating the solution of optimal control problems by fuzzy systems. Neural Process Lett 43(3):667–686

Pooya A, Faezirad M (2017) A taxonomy of manufacturing strategies and production systems using self-organizing map. J Ind Production Eng 34:300–311

Pooya A, Pakdaman M (2017) Analysing the solution of production-inventory optimal control systems by neural networks. RAIRO-Oper Res. 51(3):577–590

Pooya A, Pakdaman M, Tadj L (2017) Exact and approximate solution for optimal inventory control of two-stock with reworking and forecasting of demand. Oper Res. https://doi.org/10.1007/s12351-017-0297-6

Tang O (2000) Modelling stochastic lead times in a production-inventory system based on the laplace transform method. Int J Prod Res 38(17):4217–4226

Vercraene S, Gayon J-P (2013) Optimal control of a production-inventory system with productreturns. Int J Prod Econ 142(2):302–310

Vercraene S, YON J-PG, Jemai Z (2010) Control of a two-stage production/inventory system with products returns. IFAC Proc Volumes 43(8):232–237

Wang P, Zinn W, Croxton KL (2010) Sizing inventory when lead time and demand are correlated. Prod Oper Manag 19(4):480– 484

Warburton RD (2004) An exact analytical solution to the production inventory control problem. Int J Prod Econ 92(1):81–96

Yan X, Liu K (2009) Optimal control problems for a new product with word-of-mouth. Int J Prod Econ 119(2):402–414

Acknowledgements

The authors would like to thanks the Editor and anonymous reviewers for their valuable comments. This work was supported in part by Research Deputy of Ferdowsi University of Mashhad, under Grant No. 42067 (dated Sep. 27, 2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported in part by: Research Deputy of Ferdowsi University of Mashhad, under Grant No. 42067 (dated Sep. 27, 2016).

Rights and permissions

About this article

Cite this article

Pooya, A., Pakdaman, M. A delayed optimal control model for multi-stage production-inventory system with production lead times. Int J Adv Manuf Technol 94, 751–761 (2018). https://doi.org/10.1007/s00170-017-0942-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0942-5