Abstract

A scheme for online quality monitoring of resistance spot welding (RSW) process is proposed to effectively determine the rate of spot weld quality. In this work, the random forest (RF) classification featuring with dynamic resistance (DR) signals which were collected and processed in the production environment was carried out. The obtained results demonstrated that the constructed RF model based on DR profile features adequately distinguished high-quality welds from the other unacceptable welds such as inadequate sized welds and expulsions. Variable importance evaluation of RF was implemented against the input features. It showed that two DR slopes for nugget nucleation and growth (v 2 , v 3 ) and dynamic resistance (R γ ) in the final half cycle play the most significant roles in achieving more accurate results of classification, while absolute gradient ∇ max is useful in detecting minor expulsion from pull-out failure. In addition, shunting effect in consecutive welds was tentatively investigated via the DR curves, accounting for noticeable declines in the stage I of DR. The results revealed that shunted welds beyond minimum weld spacing do not significantly undermine the accuracy of classification. The implementation of RF based on the combination of welding parameters and DR features improves the accuracy of classification (98.8%) with ntree = 1000 and mtry = 4, as weld current significantly distinguished situations where DR features solely achieve accuracy (93.6%). The incorporation of the RF technique into online monitoring system attains a satisfying RSW quality classification accuracy and reduces the workload on destructive tests.

Similar content being viewed by others

References

Zhang H (1999) Expulsion and its influence on weld quality. WELD J-NEW YORK 78:373-s

Liu J, Xu G, Gu X, Zhou G (2015) Ultrasonic test of resistance spot welds based on wavelet package analysis. Ultrasonics 56:557–565

Wang H, Zhang Y, Chen G (2009) Resistance spot welding processing monitoring based on electrode displacement curve using moving range chart. Measurement 42:1032–1038

Gedeon S, Sorensen C, Ulrich K, Eagar T (1987) Measurement of dynamic electrical and mechanical properties of resistance spot welds. Weld J 66:378–385

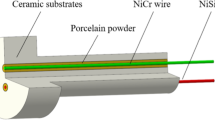

Luo Y, Rui W, Xie X, Zhu Y (2016) Study on the nugget growth in single-phase AC resistance spot welding based on the calculation of dynamic resistance. J Mater Process Technol 229:492–500

Fan Q, Xu G, Gu X (2016) Expulsion characterization of stainless steel resistance spot welding based on dynamic resistance signal. J Mater Process Technol 236:235–240

Breiman L (2001) Random forests. Mach Learn 45:5–32

Martín Ó, Pereda M, Santos JI, Galán JM (2014) Assessment of resistance spot welding quality based on ultrasonic testing and tree-based techniques. J Mater Process Technol 214:2478–2487

Pereda M, Santos J, Martín Ó, Galán J (2015) Direct quality prediction in resistance spot welding process: sensitivity, specificity and predictive accuracy comparative analysis. Sci Technol Weld Join 20:679–685

Zhang P, Zhang H, Chen J, Ma Y (2007) Quality monitoring of resistance spot welding based on electrode displacement characteristics analysis. Front Mech Eng China 2:330–335

Wan X, Wang Y, Zhao D (2016) Quality monitoring based on dynamic resistance and principal component analysis in small scale resistance spot welding process. Int J Adv Manuf Tech 86(9–12):3443–3451

Zhang H, Wang F, Xi T, Zhao J, Wang L, Gao W (2015) A novel quality evaluation method for resistance spot welding based on the electrode displacement signal and the Chernoff faces technique. Mech Syst Signal Process 62:431–443

Wang B, Lou M, Shen Q, Li Y, Zhang H (2013) Shunting effect in resistance spot welding steels—part 1: experimental study. Weld J 92:182–189

AWS D17.2 (2007) Specification for Resistance Welding for Aerospace Applications

Long H, Hu Y, Jin X, Shao J, Zhu H (2016) Effect of holding time on microstructure and mechanical properties of resistance spot welds between low carbon steel and advanced high strength steel. Comput Mater Sci 117:556–563

Liaw A, Wiener M (2002) Classification and regression by randomForest. R news 2:18–22

Provost F, Domingos P (2000) Well-trained PETs: improving probability estimation trees. CeDER Working Paper #IS-00-04, Stern School of Business, New York University, NY 10012

Wen J, Wang C, Xu G, Zhang X (2009) Real time monitoring weld quality of resistance spot welding for stainless steel. ISIJ Int 49:553–556

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was funded by Australian Research Council (Grant No. LP130101001).

Conflict of interests

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Xing, B., Xiao, Y., Qin, Q.H. et al. Quality assessment of resistance spot welding process based on dynamic resistance signal and random forest based. Int J Adv Manuf Technol 94, 327–339 (2018). https://doi.org/10.1007/s00170-017-0889-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0889-6