Abstract

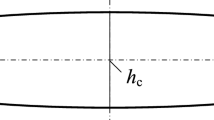

This research paper presents a comparative study of machine learning (ML) algorithms for the predictive modelling of spot-welding process parameters. The focus is on predicting the nugget diameter (ND) and nugget height (NH) using four different ML algorithms (namely, linear regression, random forest regression, adaptive boosting regression, and support vector machine regression). An experimental dataset consisting of fifty data points is used in this study. Exploratory data analysis was carried out to investigate the effect of process parameters on the response variables. Performance evaluation metrics were employed to gauge the predictive accuracy of the ML models. The results indicate that the random forest regression demonstrates superior performance in predicting both ND and NH compared to the other algorithms. This study can serve as a foundation for further research in optimizing the spot-welding process through machine learning techniques.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Rout, A., Deepak, B.B.V.L., Biswal, B.B.: Advances in weld seam tracking techniques for robotic welding: a review. Robotics and Computer-Integrated Manufacturing 56, 12–37 (2019)

Zhao, D., Ivanov, M., Wang, Y., Du, W.: Welding quality evaluation of resistance spot welding based on a hybrid approach. J. Intell. Manuf. 32, 1819–1832 (2021)

Arifin, A.: Dissimilar metal welding using shielded metal arc welding: a review. Technology Reports of Kansai University 62 (2020)

Tanaka, K., Shigeta, M., Komen, H., Tanaka, M.: Electrode contamination caused by metal vapour transport during tungsten inert gas welding. Sci. Technol. Weld. Join. 26, 258–263 (2021)

Rai, R., De, A., Bhadeshia, H.K.D.H., DebRoy, T.: Friction stir welding tools. Sci. Technol. Weld. Joining 16, 325–342 (2011)

Kahraman, N.: The influence of welding parameters on the joint strength of resistance spot-welded titanium sheets. Mater. Des. 28, 420–427 (2007)

Sudhagar, S., Sakthivel, M., Ganeshkumar, P.: Monitoring of friction stir welding based on vision system coupled with machine learning algorithm. Measurement 144, 135–143 (2019)

Kumar, B.P., Vijayakumar, Y.: Optimization of shielded metal arc welding parameters for welding of pipes by using Taguchi approach. Int. J. Eng. Sci. Technol. 4, 2083–2088 (2012)

Mishra, A., Sefene, E.M., Tsegaw, A.A.: Process Parameter Optimization of Friction Stir Welding on 6061AA Using Supervised Machine Learning Regression-based Algorithms. arXiv preprint arXiv:2109.00570 (2021)

Liang, R., Yu, R., Luo, Y., Zhang, Y.: Machine learning of weld joint penetration from weld pool surface using support vector regression. J. Manuf. Process. 41, 23–28 (2019)

Satpathy, M.P., Mishra, S.B., Sahoo, S.K.: Ultrasonic spot welding of aluminum-copper dissimilar metals: a study on joint strength by experimentation and machine learning techniques. J. Manuf. Process. 33, 96–110 (2018)

Pashazadeh, H., Gheisari, Y., Hamedi, M.: Statistical modeling and optimization of resistance spot welding process parameters using neural networks and multi-objective genetic algorithm. J. Intell. Manuf. 27, 549–559 (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Burande, D.V., Kalita, K., Chohan, J.S. (2023). Machine Learning-Based Predictive Modelling of Spot-Welding Process Parameters. In: Vasant, P., et al. Intelligent Computing and Optimization. ICO 2023. Lecture Notes in Networks and Systems, vol 729. Springer, Cham. https://doi.org/10.1007/978-3-031-36246-0_32

Download citation

DOI: https://doi.org/10.1007/978-3-031-36246-0_32

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-36245-3

Online ISBN: 978-3-031-36246-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)