Abstract

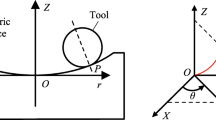

This paper presents a new polishing path planning method for physically uniform overlap of polishing ribbons instead of traditional geometrically uniform coverage of polishing path on freeform surfaces, which attempts to achieve the even material removal on the polished surface in consideration of contact mechanics in polishing process. The polishing ribbon is defined as the ribbon with varying width generated by continuous contact areas along the polishing path. The boundary extraction algorithm (BEA) is proposed to determine the specific polishing ribbon boundary which is next to the to-be-planned path. The path extraction algorithm (PEA) is given to predict the location of the adjacent polishing path. Those BEA and PEA make the overlap of polishing ribbons along two adjacent polishing paths physically uniform. Proposed polishing path planning is implemented for a typical freeform surface and the polishing paths with physically uniform overlap of polishing ribbons between two adjacent paths are obtained, while the under-polishing and over-polishing phenomena occur when the traditional scanning path is applied. In addition, the comparative experiments and analysis are also conducted and the experimental results further verify the feasibility of the proposed polishing path to promote even material removal.

Similar content being viewed by others

References

Tam HY, Cheng HB, Dong ZC (2013) Peano-like paths for subaperture polishing of optical aspherical surfaces. Appl Opt 52(15):3624–3636. doi:10.1364/AO.52.003624

Lv Z, Huang CZ, Zhu HT, Wang J, Wang Y, Yao P (2015) A research on ultrasonic-assisted abrasive waterjet polishing of hard-brittle materials. Int J Adv Manuf Technol 78(5):1361–1369. doi:10.1007/s00170-014-6528-6

Song DL, Zhao J, Ji SJ, Zhou XQ (2016) Development of a novel two-dimensional ultrasonically actuated polishing process. AIP Adv 6(11):115105. doi:10.1063/ 1.4967292

Tsai MJ, Huang JF (2006) Efficient automatic polishing process with a new compliant abrasive tool. Int J Adv Manuf Technol 30(9):817–827. doi:10.1007/s00170-005-0126-6

Liao L, Xi F, Liu K (2008) Modeling and control of automated polishing/deburring process using a dual-purpose compliant toolhead. Int J Mach Tools Manuf 48(12–13):1454–1463. doi:10.1016/j.ijmachtools.2008.04.009

Huang HY, Fuh KH, Wu JS, Tai YH (2014) A new integrated polishing process design for plastic mold steel to mirror-like surface. Int J Adv Manuf Technol 73(9):1633–1645. doi:10.1007/s00170-014-5855-y

Zhang JM (2013) An improved polishing method by force controlling and its application in aspheric surfaces ballonet polishing. Int J Adv Manuf Technol 68(9):2253–2260. doi:10.1007/ s00170-013-4814-3

Walker D, Yu GY, Li HY, Messelink W, Evans R, Beaucamp A (2012) Edges in CNC polishing: from mirror-segments towards semiconductors, paper 1: edges on processing the global surface. Opt Express 20(18):19787–19798. doi:10.1364/OE.20.019787

Pan R, Zhang YJ, Cao C, Sun M, Wang ZZ, Peng YF (2015) Modeling of material removal in dynamic deterministic polishing. Int J Adv Manuf Technol 81(9):1631–1642. doi:10.1007/s00170 -015-7267-z

Zhang L, Tam HY, Yuan C-M, Chen Y-P, Zhou Z-D (2002) An investigation of material removal in polishing with fixed abrasives. Proc Inst Mech Eng Part B J Eng Manuf 216(1):103–112. doi:10.1243/0954405021519591

Fan C, Zhao J, Zhang L, Zhou WS, Sun LN (2015) Local material removal model considering the tool posture in deterministic polishing. Proc Inst Mech Eng C J Mech Eng Sci 230(16):1989–1996. doi:10.1177/0954406215598800

Fan C, Zhao J, Zhang L, Hong GS, Wong YS, Zhao J (2014) Predictive models of the local and the global polished profiles in deterministic polishing of free-form surfaces. Proc Inst Mech Eng Part B J Eng Manuf 228(8):868–879. doi:10.1177/0954405413512813

Zhang L, Huang DP, Zhou WS, Fan C, Ji SJ, Zhao J (2016) Corrective polishing of freeform optical surfaces in an off-axis three-mirror imaging system. Int J Adv Manuf Techno 88(9):2861–2869l. doi:10.1007/s00170-016-8995-4

Tsai MJ, Fang JJ, Chang JL (2004) Robotic path planning for an automatic mold polishing system. Int J Robot Autom 19(2):81–90. doi:10.2316/Journal.206.2004.2.206-2720

Pessoles X, Tournier C (2009) Automatic polishing process of plastic injection molds on a 5-axis milling center. J Mater Process Technol 209(7):3665–3673. doi:10.1016/j.jmatprotec.2008. 08.034

Hauth S, Linsen L (2011) Double-spiral tool path in configuration space. Int J Adv Manuf Technol 54(9):1011–1022. doi:10.1007/s00170-010-3004-9

Hauth S, Linsen L (2012) Cycloids for polishing along double-spiral toolpaths in configuration space. Int J Adv Manuf Technol 60(1):343–356. doi:10.1007/s00170-011-3608-8

Sun YW, Feng DY, Guo DM (2015) An adaptive uniform toolpath generation method for the automatic polishing of complex surfaces with adjustable density. Int J Adv Manuf Technol 80(9):1673–1683. doi:10.1007/s00170-015-7140-0

Wang SZ, Liu J, Zhang LH (2013) Dual-rotor tool path generation and removal error analysis in active feed polishing. Appl Opt 52(28):6948–6955. doi:10.1364/AO.52.006948

Liu J, Wang SZ, Zhang CL, Zhang LH, Chen HN (2015) Path planning and parameter optimization of uniform removal in active feed polishing. Opt Eng 54(6):065101. doi:10.1117/1.OE. 54.6.06510 1

Tam HY, Cheng H (2010) An investigation of the effects of the tool path on the removal of material in polishing. J Mater Process Technol 210(5):807–818. doi:10.1016/j.jmatprotec.2010.01. 012

Lin W, Xu P, Li B, Yang X (2014) Path planning of mechanical polishing process for freeform surface with a small polishing tool. Robot Biomimetics 1(1):1–15. doi:10.1186/s40638-014-0024-1

Julien C-J, Linares J-M, Sprauel J-M (2013) Improving tool wear and surface covering in polishing via toolpath optimization. J Mater Process Technol 213(10):1661–1668. doi:10.1016/ j.jmatprotec.2013.04.005

Tam HY, Lui OCH, Mok ACK (1999) Robotic polishing of free-form surfaces using scanning paths. J Mater Process Technol 95(1–3):191–200. doi:10.1016/S0924-0136(99)00338-6

Tam HY (1999) Toward the uniform coverage of surfaces by scanning curves. CAD Comput Aided Des 31(9):585–596. doi:10.1016/S0010-4485(99)00054-8

Feng DY, Sun YW, Du HP (2014) Investigations on the automatic precision polishing of curved surfaces using a five-axis machining centre. Int J Adv Manuf Technol 72(9):1625–1637. doi:10.1007/s00170-014-5774-y

Pan R, Zhang YJ, Ding JB, Cao C, Wang ZZ, Jiang T, Peng YP (2016) Rationality optimization of tool path spacing based on dwell time calculation algorithm. Int J Adv Manuf Technol 84(9):2055–2065. doi:10.1007/s00170-015-7838-z

Guo W, Hua M, Tse PWT, Mok ACK (2012) Process parameters selection for laser polishing DF2 (AISIO1) by Nd:YAG pulsed laser using orthogonal design. Int J Adv Manuf Technol 59(9):1009–1023. doi:10.1007/s00170-011-3558-1

Khakpour H, Birglen L, Tahan SA (2015) Uniform scanning path generation for abrasive waterjet polishing of free-form surfaces modeled by triangulated meshes. Int J Adv Manuf Technol 77(5):1167–1176. doi:10.1007/s00170-014-6504-1

Rososhansky M, Xi F (2011) Coverage based tool-path planning for automated polishing using contact mechanics theory. J Manuf Syst 30(3):144–153. doi:10.1016/j.jmsy.2011.05.003

Tian F, Lv C, Li Z, Liu G (2016) Modeling and control of robotic automatic polishing for curved surfaces. CIRP J Manuf Sci Technol 14:55–64. doi:10.1016/j.cirpj.2016.05.010

Greenwood JA (1997) Analysis of elliptical Hertzian contacts. Tribol Int 30(3):235–237. doi:10.1016/S0301-679X(96)00051-5

Piegl L, Tiller W (1997) The NURBS book, 2nd edn. Springer, New York

Goldfeather J, Interrante V (2004) A novel cubic-order algorithm for approximating principal direction vectors. ACM Trans Graph 23(1):45–63

An Y, Shao C, Wang XL, Li ZH (2011) Estimating principal curvatures and principal directions from discrete surfaces using discrete curve model. Journal of Information & Computational Science 8(2):296–311

Schwetlick H, Schütze T (1995) Least squares approximation by splines with free knots. BIT Numer Math 35(3):361–384. doi:10.1007/BF01732610

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Han, Y., Fan, C. et al. Polishing path planning for physically uniform overlap of polishing ribbons on freeform surface. Int J Adv Manuf Technol 92, 4525–4541 (2017). https://doi.org/10.1007/s00170-017-0466-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0466-z