Abstract

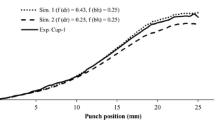

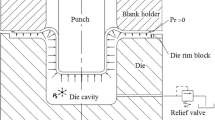

Investigation of friction is carried out in the radial drawing region between the die and blank holder and also in the stretching zone over the punch in deep drawing. Two methods are developed to calculate the coefficient of friction in each zone using the experimentally determined data such as punch force diagrams and strain distributions obtained by an optical scanning system. The current methods differ from the existing techniques which are obtained in simulative tests. The proposed methods can be applied in room temperature and at elevated temperatures. Comparisons of friction coefficients are made with those obtained by other techniques.

Similar content being viewed by others

References

Kaftanolu B (1973) Determination of coefficient of friction under conditions of deep-drawing and stretch forming. Wear 25/2:177–188

Kaftanoglu B, Alexander JM (1961) An Investigation of the Erichsen Test. J Inst Met 90:457–470

Subramonian S, Kardes N, Demiralp Y, Jurich M, Altan T (2011) Evaluation of stamping lubricants in forming galvannealed steels for industrial application. J Manuf Sci Eng 133/6:061001– 9

Yanagida A, Azushima A (2009) Evaluation of coefficients of friction in hot stamping by hot flat drawing test. Ann CIRP 58/1:247–250

Bech J, Bay N, Eriksen M (1998) A study of mechanisms of liquid lubrication in metal forming. Ann CIRP 47/1:221–226

Meng B, Fu MW, Wan M (2014) Um sheet in deep-drawing process at elevated temperature. Int J Adv Manuf Technol 78:1005–1014

Dilmec M, Arap M (2016) Effect of geometrical and process parameters on coefficient of friction in deep drawing process at the flange and the radius regions. Int J Adv Manuf Technol 86:747–759

Schmoeckel D, Prier M, Staeves J (1997) Topography deformation of sheet metal during the forming process and its influence on friction. Ann CIRP 46/1:175–178

Berglund J, Brown CA, Rosén BG, Bay N (2010) Milled die steel surface roughness correlation with steel sheet friction. Ann CIRP 59/1:577–580

Jeon J, Bramley AN (2007) A friction model formicroforming. Int J Adv Manuf Technol 33:125–129

Klocke F, Trauth D, Shirobokov A, Mattfeld P (2015) FE-Analysis and in situ visualization of pressure-, slip-rate- and temperature-dependent coefficients of friction for advanced sheet metal forming: development of a novel coupled user subroutine for shell and continuum discretization,. Int J Adv Manuf Technol 81:397–410

Makinouchi A, Teodosiu C, Nakagawa T (1998) Advance in FEM Simulation and its Related Technologies in Sheet Metal Forming. Ann CIRP 47/2:641–649

Vollertsen F, Hu Z (2006) Tribological size effects in sheet metal forming measured by a strip drawing test. Ann CIRP 55/1:291–294

Azushima A, Kudo H (1995) Direct observation of contact behaviour to interpret the pressure dependence of the coefficient of friction in sheet metal forming. Ann CIRP 44/1:209–212

Figueiredo L, Ramalho A, Oliveira MC, Menezes LF (2011) Experimental study of friction in sheet metal forming. Wear 271/910:1651–1657

Fratini L, Lo Casto S, Lo Valvo E (2006) A technical note on an experimental device to measure friction coefficient in sheet metal forming. J Mater Process Technol 172/1:16–21

Weinmann KJ, Kernosky SK (1996) Friction studies in sheet metal forming based on a unique die shoulder force transducer. Ann CIRP 45/1:269–272

Yanagida A, Azushima A (2009) Evaluation of coefficients of friction in hot stamping by hot flat drawing test. Ann CIRP 58/1:247–50

Acknowledgements

This research was funded with the BAP Project at Atilim University. (ATU-BAP-A-1213-06). The authors would like to thank the Metal Forming Center of Excellence (MFCE) and BOREN Center of Competence for Boron Coating at Atilim University, for the facilities used in the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kalkan, H., Hacaloglu, T. & Kaftanoglu, B. Experimental investigation of friction in deep drawing. Int J Adv Manuf Technol 92, 3311–3318 (2017). https://doi.org/10.1007/s00170-017-0401-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0401-3