Abstract

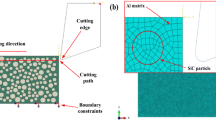

A three-dimension (3D) finite element (FE) end milling model with equivalent homogenous material (EHM) model, which was drawn from the quasi-static and SHPB (Split Hopkinson pressure bar) tests, has been developed by using ABAQUS/Explicit in order to describe the machining process of SiCp/Al6063/30P composites. The model is verified by milling experiments and it is found that the predicted milling forces at different combinations of feed rate and rotation speed are consistent with those in milling experiments, and the prediction error of the peak value of F y and F x can be controlled within 20%. Moreover, the general shapes of the predicted chips are very similar to the experimental ones, but the application of EHM material model leading to the limitation of the simulated chip morphology such as cracks on chip contact surface and free surface caused by the existence of hard SiC particles cannot be described. Hence, further microstructure-level 3D FEM model which can reveal the interactions between particles and matrix and their effect on the chip formation mechanism of SiCp/Al6063composites becomes very necessary.

Similar content being viewed by others

References

Lin JT, Bhattacharyya D, Lane C (1995) Machinability of a silicon carbide reinforced aluminium metal matrix composite. Wear 181–183(95):883–888

Wang Z, Chen TK, Lloyd DJ (1993) Stress distribution in particulate-reinforced metal-matrix composites subjected to external load. Metall Mater Trans A 24(1):197–207

El-Gallab M, Sklad M (1998) Machining of Al/SiC particulate metal matrix composites : part II: workpiece surface integrity. J Mater Process Technol 83(1–3):277–285

Yang J (2012)The FEM and experimental research of SiC/Al in precision milling. Haerbin Institute of Technology

Bao G, Hutchinson JW, Mcmeeking RM (1991) Particle reinforcement of ductile matrices against plastic flow and creep. ActaMetallurgicaEtMaterialia 39(8):1871–1882

Li Y, Ramesh KT, Chin ESC (2004) The mechanical response of an a359/sicp, mmc and the a359 aluminum matrix to dynamic shearing deformations. Mater Sci Eng A 382(1–2):162–170

Li Y, Ramesh KT, Chin ESC (2004) Comparison of the plastic deformation and failure of A359/SiC and 6061-T6/Al 2 o 3, metal matrix composites under dynamic tension. Mater Sci Eng A 371(1–2):359–370

Li Y, Ramesh KT (1998) Influence of particle volume fraction, shape, and aspect ratio on the behavior of particle-reinforced metal–matrix composites at high rates of strain. Acta Mater 46(46):5633–5646

Dandekar CR, Shin YC (2013) Multi-scale modeling to predict sub-surface damage applied to laser-assisted machining of a particulate reinforced metal matrix composite. J Mater Process Technol 213(2):153–160

Fathipour M, Zoghipour P, Tarighi J, Yousefi R (2012) Investigation of reinforced sic particles percentage on machining force of metal matrix composite. Mod Appl Sci 6(8):9–20

Zhu Y, Kishawy HA (2005) Influence of alumina particles on the mechanics of machining metal matrix composites. Int J Mach Tools Manuf 45(4):389–398

Pramanik A, Zhang LC, Arsecularatne JA (2007) An FEM investigation into the behavior of metal matrix composites: tool–particle interaction during orthogonal cutting. Neural Parallel Sci Comput 47(10):1497–1506

Monaghan J, Brazil D (1997) Modeling the sub-surface damage associated with the machining of a particle reinforced mmc. Comput Mater Sci 9(1):99–107

Monaghan J, Brazil D (1998) Modelling the flow processes of a particle reinforced metal matrix composite during machining. Compos A Appl Sci Manuf 29(1–2):87–99

Wang B, Xie L, Chen X, Wang X (2016) The milling simulation and experimental research on high volume fraction of SiCp/Al. Int J Adv Manuf Technol 82(5–8):809–816

Zhou L, Huang ST, Wang D, Yu XL (2011) Finite element and experimental studies of the cutting process of SiCp/Al composites with PCD tools. Int J Adv Manuf Technol 52(5):619–626

Wang T, Xie L, Wang X (2015) Simulation study on defect formation mechanism of the machined surface in milling of high volume fraction SiCp/Al composite. Int J Adv Manuf Technol 79(5):1185–1194

Umer U, Ashfaq M, Qudeiri JA, Hussein HMA, Danish SN, Al-Ahmari AR (2015) Modeling machining of particle-reinforced aluminum-based metal matrix composites using cohesive zone elements. Int J Adv Manuf Technol 78(5–8):1171–1179

Kishawy HA, Kannan S, Balazinski M (2004) An energy based analytical force model for orthogonal cutting of metal matrix composites. CIRP Ann Manuf Technol 53(1):91–94

Kannan S, Kishawy HA (2008) Tribological aspects of machining aluminium metal matrix composites. J Mater Process Technol 198(1):399–406

Dattatray MP, Suhas SJ (2004) Modeling and optimization of machining process in discontinuously reinforced aluminium matrix composites. Mach Sci Technol Int J 8(1):85–102

Wang T, Xie L, Wang X, Ding Z (2015) PCD tool performance in high-speed milling of high volume fraction SiCp/Al composites. Int J Adv Manuf Technol 78(9):1445–1453

Dabade UA, Sonawane HA, Joshi SS (2010) Cutting forces and surface roughness in machining Al/SiCp composites of varying composition. Mach Sci Technol 14(2):258–279

Yadav S, Chichili DR, Ramesh KT (1995) The mechanical response of a 6061-T6 A1/A12O3, metal matrix composite at high rates of deformation. Acta Metall Mater 43(12):4453–4464

Lin ZC, Lin SY (1992) A coupled finite element model of thermo-elastic-plastic large deformation for orthogonal cutting. J Eng Mater Technol 114(2):218–226

Strenkowski JS, Carroll JT (1985) A finite element model of orthogonal metal cutting. J Eng Ind 107(4):349–354

Komvopoulos K, Erpenbeck SA (1991) Finite element modeling of orthogonal metal cutting. J Eng Ind 113(3):253–267

Zhang L (1999) On the separation criteria in the simulation of orthogonal metal cutting using the finite element method. J Mater Process Technol 89–90(99):273–278

Pramanik A, Zhang LC, Arsecularatne JA (2006) Prediction of cutting forces in machining of metal matrix composites. Int J Mach Tools Manuf 46(14):1795–1803

Li W, Chen J, He JJ, Ren YJ, Qiu W, Zhu SQ, Sun YP (2014) Effect of the SiC particle orientation anisotropy on the tensile properties of a spray-formed SiCp/Al-Si composite. Strength Mater 46(2):221–228

Jeong H, Hsu D K, Shannon R E, Liaw P K (1990). Elastic moduli of silicon carbide particulate reinforced aluminum metal matrix composites. Review of Progress in Quantitative Nondestructive Evaluation. Springer US

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Xie, L., Xue, X. et al. Research on 3D milling simulation of SiCp/Al composite based on a phenomenological model. Int J Adv Manuf Technol 92, 2715–2723 (2017). https://doi.org/10.1007/s00170-017-0315-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0315-0