Abstract

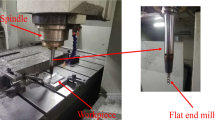

Performance and service life of aerospace component are significantly influenced by surface integrity, especially for cyclically loaded thin-walled structure component. This work focuses on the surface roughness and residual stress of machined surface, which are considered the most important indications of surface integrity, for inclined end milling Ni-based superalloy Inconel 718. The purpose is to minimize surface roughness and maximize compressive residual stress by optimizing the cutter geometry. Based on the grey relational analysis (GRA), an integrated multi-objective optimization approach with the radial basis function (RBF) neural network and the firefly algorithm (FA) is developed. The end-tooth rake angle, end-tooth relief angle, and helix angle are selected as design factors, while the residual stress and the 3D surface roughness are taken as performance characteristics. The orthogonal array L16 (43) is employed to generate sample data set. Then, the GRA is introduced to search the most influential factor by the grey relational grade (GRG). Subsequently, the proposed grey-RBF-FA method is applied to the multi-objective optimization problem. After calculating the GRG, the RBF network is used to relate the GRG with cutter geometric parameters. The test data show the RBF model has a low prediction error of 11.11%. Finally, the FA is utilized to search the optimal parameter-level combination. Validation experiments show that, compared with the original GRA, the proposed method further greatly improves the surface roughness and residual stresses in both directions by 1.20 μm, 249.1 MPa, and 176.5 MPa, respectively. The developed approach is proved to be feasible and can be generalized for other multi-objective optimization in manufacturing industry.

Similar content being viewed by others

References

Liu C, Ren CZ, Wang GF, Yang YW, Zhang L (2015) Study on surface defects in milling Inconel 718 super alloy. J Mech Sci Technol 29(4):1723–1730. doi:10.1007/s12206-015-0345-1

Thakur DG, Ramamoorthy B, Vijayaraghavan L (2012) Effect of cutting parameters on the degree of work hardening and tool life during high-speed machining of Inconel 718. Int J Adv Manuf Technol 59(5–8):483–489. doi:10.1007/s00170-011-3529-6

Jafarian F, Amirabadi H, Sadri J (2015) Experimental measurement and optimization of tensile residual stress in turning process of Inconel718 superalloy. Measurement 63:1–10. doi:10.1016/j.measurement.2014.11.021

Pawade RS, Joshi SS, Brahmankar PK (2008) Effect of machining parameters and cutting edge geometry on surface integrity of high-speed turned Inconel 718. Int J Mach Tools Manuf 48(1):15–28. doi:10.1016/j.ijmachtools.2007.08.004

Pawade RS, Joshi SS (2011) Multi-objective optimization of surface roughness and cutting forces in high-speed turning of Inconel 718 using Taguchi grey relational analysis (TGRA). Int J Adv Manuf Technol 56(1–4):47–62. doi:10.1007/s00170-011-3183-z

Pusavec F, Hamdi H, Kopac J, Jawahir IS (2011) Surface integrity in cryogenic machining of nickel based alloy—Inconel 718. J Mater Process Technol 211(4):773–783. doi:10.1016/j.jmatprotec.2010.12.013

Umbrello D (2013) Investigation of surface integrity in dry machining of Inconel 718. Int J Adv Manuf Technol 69(9–12):2183–2190. doi:10.1007/s00170-013-5198-0

Cai XJ, Qin S, Li JL, An QL, Chen M (2014) Experimental investigation on surface integrity of end milling nickel-based alloy Inconel 718. Mach Sci Technol 18(1):31–46. doi:10.1080/10910344.2014.863627

Ma JW, Wang FJ, Jia ZY, Xu Q, Yang YY (2014) Study of machining parameter optimization in high speed milling of Inconel 718 curved surface based on cutting force. Int J Adv Manuf Technol 75(1–4):269–277. doi:10.1007/s00170-014-6115-x

Jafarian F, Amirabadi H, Fattahi M (2014) Improving surface integrity in finish machining of Inconel 718 alloy using intelligent systems. Int J Adv Manuf Technol 71(5–8):817–827. doi:10.1007/s00170-013-5528-2

Jiang F, Li J, Yan L, Sun J, Zhang S (2010) Optimizing end-milling parameters for surface roughness under different cooling/lubrication conditions. Int J Adv Manuf Technol 51(9–12):841–851. doi:10.1007/s00170-010-2680-9

Cantero JL, Diaz-Alvarez J, Miguelez MH, Marin NC (2013) Analysis of tool wear patterns in finishing turning of Inconel 718. Wear 297(1–2):885–894. doi:10.1016/j.wear.2012.11.004

Devillez A, Le Coz G, Dominiak S, Dudzinski D (2011) Dry machining of Inconel 718, workpiece surface integrity. J Mater Process Technol 211(10):1590–1598. doi:10.1016/j.jmatprotec.2011.04.011

M’Saoubi R, Larsson T, Outeiro J, Guo Y, Suslov S, Saldana C, Chandrasekar S (2012) Surface integrity analysis of machined Inconel 718 over multiple length scales. CIRP Ann-Manuf Technol 61(1):99–102. doi:10.1016/j.cirp.2012.03.058

Fan YH, Hao ZP, Zheng ML, Sun FL, Yang SC (2013) Study of surface quality in machining nickel-based alloy Inconel 718. Int J Adv Manuf Technol 69(9–12):2659–2667. doi:10.1007/s00170-013-5225-1

Akhtar W, Sun J, Chen W (2016) Effect of machining parameters on surface integrity in high speed milling of super alloy GH4169/Inconel 718. Mater Manuf Process 31(5):620–627

Madariaga A, Esnaola JA, Fernandez E, Arrazola PJ, Garay A, Morel F (2014) Analysis of residual stress and work-hardened profiles on Inconel 718 when face turning with large-nose radius tools. Int J Adv Manuf Technol 71(9–12):1587–1598. doi:10.1007/s00170-013-5585-6

Sharman ARC, Hughes JI, Ridgway K (2015) The effect of tool nose radius on surface integrity and residual stresses when turning Inconel 718 (TM). J Mater Process Technol 216:123–132. doi:10.1016/j.jmatprotec.2014.09.002

Taşkesen A, Kütükde K (2014) Experimental investigation and multi-objective analysis on drilling of boron carbide reinforced metal matrix composites using grey relational analysis. Measurement 47:321–330. doi:10.1016/j.measurement.2013.08.040

Goel B, Singh S, Sarepaka RV (2015) Optimizing single point diamond turning for mono-crystalline germanium using grey relational analysis. Mater Manuf Process 30(8):1018–1025. doi:10.1080/10426914.2014.984207

Sarikaya M, Yilmaz V, Dilipak H (2016) Modeling and multi-response optimization of milling characteristics based on Taguchi and gray relational analysis. Proc Inst Mech Eng Part B-J Eng Manuf 230(6):1049–1065. doi:10.1177/0954405414565136

Prasanna J, Karunamoorthy L, Venkat Raman M, Prashanth S, Raj Chordia D (2014) Optimization of process parameters of small hole dry drilling in Ti–6Al–4V using Taguchi and grey relational analysis. Measurement 48:346–354. doi:10.1016/j.measurement.2013.11.020

Tang L, Du YT (2014) Multi-objective optimization of green electrical discharge machining Ti–6Al–4 V in tap water via grey-Taguchi method. Mater Manuf Process 29(5):507–513. doi:10.1080/10426914.2013.840913

Kumar SS, Uthayakumar M, Kumaran ST, Parameswaran P, Mohandas E, Kempulraj G, Babu BSR, Natarajan SA (2015) Parametric optimization of wire electrical discharge machining on aluminium based composites through grey relational analysis. J Manuf Process 20:33–39. doi:10.1016/j.jmapro.2015.09.011

Nelabhotla DM, Jayaraman TV, Asghar K, Das D (2016) The optimization of chemical mechanical planarization process-parameters of c-plane gallium-nitride using Taguchi method and grey relational analysis. Mater Des 104:392–403. doi:10.1016/j.matdes.2016.05.031

Jangra KK, Sharma N, Khanna R, Matta D (2016) An experimental investigation and optimization of friction stir welding process for AA6082 T6 (cryogenic treated and untreated) using an integrated approach of Taguchi, grey relational analysis and entropy method. Proc Inst Mech Eng Pt L-J Mater-Design Appl 230(2):454–469. doi:10.1177/1464420715578182

Ghetiya ND, Patel KM, Kavar AJ (2016) Multi-objective optimization of FSW process parameters of aluminium alloy using Taguchi-based grey relational analysis. Trans Indian Inst Metals 69(4):917–923. doi:10.1007/s12666-015-0581-1

Ren J, Zhou J, Zeng J (2015) Analysis and optimization of cutter geometric parameters for surface integrity in milling titanium alloy using a modified grey-Taguchi method. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture: 1–15. doi: 10.1177/0954405415599927

Ren JX, Zhou JH, Wei JW (2015) Optimization of cutter geometric parameters in end milling of titanium alloy using the grey-Taguchi method. Advances in Mechanical Engineering 7(2):1–10. doi:10.1155/2014/721093

Meng F, Dong Q, Wang P, Wang Y (2014) Multiobjective optimization for the impeller of centrifugal fan based on response surface methodology with grey relational analysis method. Advances in Mechanical Engineering 6:1–13

Adalarasan R, Santhanakumar M, Rajmohan M (2015) Optimization of laser cutting parameters for Al6061/SiCp/Al2O3 composite using grey based response surface methodology (GRSM). Measurement 73:596–606. doi:10.1016/j.measurement.2015.06.003

Adalarasan R, Santhanakumar M, Rajmohan M (2015) Application of grey Taguchi-based response surface methodology (GT-RSM) for optimizing the plasma arc cutting parameters of 304 L stainless steel. Int J Adv Manuf Technol 78(5–8):1161–1170. doi:10.1007/s00170-014-6744-0

Adalarasan R, Sundaram AS (2015) Parameter design in friction welding of Al/SiC/Al2O3 composite using grey theory based principal component analysis (GT-PCA). J Braz Soc Mech Sci Eng 37(5):1515–1528. doi:10.1007/s40430-014-0294-0

Dao T-P (2016) Multiresponse optimization of a compliant guiding mechanism using hybrid Taguchi-grey based fuzzy logic approach. Math Probl Eng 2016:1–18

Yeh J-H, Tsai T-N (2014) Optimizing the fine-pitch copper wire bonding process with multiple quality characteristics using a grey-fuzzy Taguchi method. Microelectron Reliab 54(1):287–296. doi:10.1016/j.microrel.2013.09.001

Gok A (2015) A new approach to minimization of the surface roughness and cutting force via fuzzy TOPSIS, multi-objective grey design and RSA. Measurement 70:100–109. doi:10.1016/j.measurement.2015.03.037

Ramesh S, Viswanathan R, Ambika S (2016) Measurement and optimization of surface roughness and tool wear via grey relational analysis, TOPSIS and RSA techniques. Measurement 78:63–72. doi:10.1016/j.measurement.2015.09.036

Yin YM, Cui HY, Hong M, Zhao DY (2015) Prediction of the vertical vibration of ship hull based on grey relational analysis and SVM method. J Mar Sci Technol 20(3):467–474. doi:10.1007/s00773-014-0299-5

Basak S, Dixit US, Davim JP (2007) Application of radial basis function neural networks in optimization of hard turning of AISI D2 cold-worked tool steel with a ceramic tool. Proc Inst Mech Eng Part B-J Eng Manuf 221(6):987–998. doi:10.1243/09544054jem737

Pontes FJ, de Paiva AP, Balestrassi PP, Ferreira JR, da Silva MB (2012) Optimization of radial basis function neural network employed for prediction of surface roughness in hard turning process using Taguchi’s orthogonal arrays. Expert Syst Appl 39(9):7776–7787. doi:10.1016/j.eswa.2012.01.058

Shanmukhi K, Vundavilli PR, Surekha B (2015) Modeling of ECDM micro-drilling process using GA- and PSO-trained radial basis function neural network. Soft Comput 19(8):2193–2202. doi:10.1007/s00500-014-1400-z

Raja SB, Pramod CVS, Krishna KV, Ragunathan A, Vinesh S (2015) Optimization of electrical discharge machining parameters on hardened die steel using firefly algorithm. Eng Comput 31(1):1–9. doi:10.1007/s00366-013-0320-3

Varun A, Venkaiah N (2015) Grey relational analysis coupled with firefly algorithm for multiobjective optimization of wire electric discharge machining. Proc Inst Mech Eng Part B-J Eng Manuf 229(8):1385–1394. doi:10.1177/0954405414535591

Li MF, Zhang YY, Zeng B, Zhou HM, Liu JG (2016) The modified firefly algorithm considering fireflies’ visual range and its application in assembly sequences planning. Int J Adv Manuf Technol 82(5–8):1381–1403. doi:10.1007/s00170-015-7457-8

Tzeng C-J, Lin Y-H, Yang Y-K, Jeng M-C (2009) Optimization of turning operations with multiple performance characteristics using the Taguchi method and grey relational analysis. J Mater Process Technol 209(6):2753–2759

Haykin S, Network N (2004) A comprehensive foundation. Neural Netw 2(2004)

Yang X-S (2009) Firefly algorithms for multimodal optimization. In: Stochastic algorithms: foundations and applications. Springer, pp 169–178

Yang X-S (2013) Multiobjective firefly algorithm for continuous optimization. Eng Comput 29(2):175–184

Yang X-S, He X (2013) Firefly algorithm: recent advances and applications. International Journal of Swarm Intelligence 1(1):36–50

Jailani HS, Rajadurai A, Mohan B, Kumar AS, Sornakumar T (2009) Multi-response optimisation of sintering parameters of Al–Si alloy/fly ash composite using Taguchi method and grey relational analysis. Int J Adv Manuf Technol 45(3–4):362–369. doi:10.1007/s00170-009-1973-3

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhou, J., Ren, J. & Tian, W. Grey-RBF-FA method to optimize surface integrity for inclined end milling Inconel 718. Int J Adv Manuf Technol 91, 2975–2993 (2017). https://doi.org/10.1007/s00170-016-9897-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9897-1