Abstract

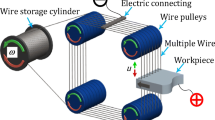

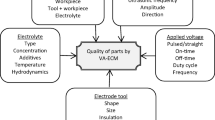

Narrow slits are widely used in aerospace, instrument and meter, and heat-transfer equipment. Electrochemical machining (ECM) has the advantage of being free of tool wear, heat-affected zone, and machining deformation, and is suitable for high-precision machining of narrow slits. However, conventional cathodic continuous linear feeding causes serious stray removal at the narrow slit side wall and results in poor forming precision. This paper presents a new compound feeding method with vibration superimposed on a continuous linear feeding method and investigates the electrochemical machining of a narrow slit using this method. Its influence on narrow slit formation based on the numerical analysis of an electric field is studied as well. The results indicate that compound feeding is superior to linear feeding in terms of less stray removal and a smaller slit width. Comparative experiments of the compound and linear feeding with voltage pulses are also conducted based on a self-developed ECM system, with vibration frequencies from 0 to 50 Hz and vibration amplitudes from 0 to 2 mm. The results demonstrate that not only the average slit width and side-wall slope are smaller, but also the localization of the narrow slit electrochemical machining can be significantly enhanced by compound feeding.

Similar content being viewed by others

References

Yao Y, Zhang JZ, Wang LP (2013) Film cooling on a gas turbine blade suction side with converging slot-hole. Int J Therm Sci 65:267–279

Deng DX, Tang Y, Zeng J, Yang S, Shao HR (2014) Characterization of capillary rise dynamics in parallel micro V-grooves. Int J Heat Mass Tran 77:311–320

Oh KH, Lee MK, Jeong SH (2006) Laser micro machining of high-aspect-ratio metallic grooves for application to microthermal devices. J Micromech Microeng 16(10):1958–1966

Yao Y, Zhang JZ, Tan XM (2014) Numerical study of film cooling from converging slot-hole on a gas turbine blade suction side. Int Commun Heat Mass 52:61–72

Altena HSJ (2004) EDM and ECM for mass production Philips DAP. J Mater Process Technol 149(1–3):18–21

Rathod V, Doloi B, Bhattacharyya B (2014) Sidewall insulation of microtool for electrochemical micro- machining to enhance the machining accuracy. Mater Manuf Process 29(3):305–313

Wang J, Chen W, Gao F, Han FZ (2014) A new electrode sidewall insulation method in electrochemical drilling. Int J Adv Manuf Technol 75(1):21–32

Fang XL, Qu NS, Li HS, Zhu D (2013) Enhancement of insulation coating durability in electrochemical machining. Int J Adv Manuf Technol 68(9):2005–2013

Zhu ZW, Wang DY, Bao J, Wang NF, Zhu D (2015) Cathode design and experimental study on the rotate-print electrochemical machining of revolving parts. Int J Adv Manuf Technol 80(9):1957–1963

Fang XL, Zhang PF, Zeng YB, Qu NS, Zhu D (2016) Enhancement of performance of wire electrochemical micromachining using a rotary helical electrode. J Mater Process Technol 227:129–137

Liu GX, Zhang YJ, Jiang SZ, Liu JW, Gyimah GK, Luo HP (2016) Investigation of pulse electrochemical sawing machining of micro-inner annular groove on metallic tube. Int J Mach Tool Manu 102:22–34

Fang XL, Zou XH, Zhang PF, Zeng YB, Qu NS (2016) Improving machining accuracy in wire electrochemical micromachining using a rotary helical electrode. Int J Adv Manuf Technol 84(5):929–939

Yuan Y, Han LH, Huang D, Su JJ, Tian ZQ, Tian ZW, Zhan DP (2015) Electrochemical micromachining under mechanical motion mode. Electrochim Acta 183:3–7

Mithu MAH, Fantoni G, Ciampi J (2011) The effect of high frequency and duty cycle in electrochemical microdrilling. Int J Adv Manuf Technol 55(9):921–933

Lee ES, Baek SY, Cho CR (2007) A study of the characteristics for electrochemical micromachining with ultrashort voltage pulses. Int J Adv Manuf Technol 31(7):762–769

Silva AKMD, Altena HSJ, McGeough JA (2000) Precision ECM by process characteristic modeling. CIRP Ann-Manuf Techn 49(1):151–155

Pan Y, Xu LZ (2015) Vibration analysis and experiments on electrochemical micro-machining using cathode vibration feed system. Int J Precis Eng Manuf 16(1):143–149

Hewidy MS, Ebeid SJ, El-Taweel TA, Youssef AH (2007) Modelling the performance of ECM assisted by low frequency vibrations. J Mater Process Technol 189(1–3):466–472

Xu LZ, Pan Y (2014) Electrochemical micromachining using vibrating tool electrode. Int J Adv Manuf Technol 75(5):645–650

Wang SH, Zhu D, Zeng YB, Liu Y (2011) Micro wire electrode electrochemical cutting with low frequency and small amplitude tool vibration. Int J Adv Manuf Technol 53(5):535–544

Qu NS, Xu K, Zeng YB, Yu Q (2013) Enhancement of the homogeneity of micro slits prepared by wire electrochemical micromachining. Int J Electrochem Sci 8:12163–12171

Ghoshal B, Bhattacharyya B (2013) Influence of vibration on micro-tool fabrication by electrochemical machining. Int J Mach Tool Manu 64:49–59

Qian SQ, Ji F, Qu NS, Li HS (2014) Improving the localization of surface texture by electrochemical machining with auxiliary anode. Mater Manuf Process 29(11–12):1488–1493

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, W., Jianshe, Z., Xiangli, Z. et al. Electrochemical machining of a narrow slit by cathodic compound feeding. Int J Adv Manuf Technol 90, 971–978 (2017). https://doi.org/10.1007/s00170-016-9448-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9448-9