Abstract

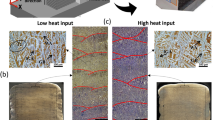

The characterization of dissimilar metal welds is a promising area to understand the behavior of the weld joints. The previous study shows the characterization of similar and dissimilar metal welding of 1 mm and above thick sheets for changes in weld bead geometry, chemical composition and mechanical properties at different process parameters. The objective of this paper is to study the influence of Nd: YAG laser welding process parameters on 0.5 mm thick sheets to understand the overall behavioral characteristics of 304 L stainless steel and galvanized iron. The experiments are conducted as per Taguchi’s orthogonal array design matrix. The samples are welded at different process parameters and examined for the variation in the microstructure, chemical composition, weld defects, grain size, phase contents, microstrain and dislocation density across the weld joint. The laser power and pulse duration are significantly affecting process parameters on weld bead geometry, porosity, mixing of metals and weld strength. The factors responsible for the reduction in weld strength are also identified. These findings are useful to understand the overall changes in weld characteristics and variation in mechanical properties. This study also helps to select process parameters for obtaining better quality weld joints in micro component welding.

Similar content being viewed by others

References

Balasubrimanian RR, Shivshanmugam N, Bhavanashankara G, Shankarnarayanswamy K (2008) Numerical and experimental investigation of laser beam welding of AISI 304 SS sheet. International Journal of Advances in Production Engineering and Management 3(2):93–105

Lee HT, Jeng SL (2001) Characteristics of dissimilar welding of alloy 690 to 304 L stainless steel. Sci Technol Weld Join 6(4):225–234

Jamshidi AH, Farzadi A, Serajzadeh S, Kokabi AH (2008) Theoretical and experimental study of microstructures and weld pool geometry during GTAW of 304 stainless steel. Int J Adv Manuf Technol. doi:10.1007/ s00170-008-1663-6

Benyounis KY, Olabi AG, Hashmi MSJ (2005) Effect of laser welding parameters on the heat input and weld-bead profile. J Mater Process Technol 64:978–985

Khan MMA, Romoli L, Marco F, Dini G, Sarri F (2012) Multiresponse optimization of laser welding of stainless steels in a constrained fillet joint configuration using RSM. Int J Adv Manuf Technol 62(5–8):587–603

Seyed MH, Hasanniya MH, Nooshin S, Valizadeh E (2013) CO2 laser welding of interstitial free galvanized steel sheets used in tailor welded blanks. Int J Adv Manuf Technol 64(1–4):195–206

Fabrizia C, Vittorio AI, Vincenzo SI, Angelo S, Salvatore C (2013) Dissimilar autogenous disk-laser welding of Haynes 188 and Inconel 718 super alloys for aerospace applications. Int J Adv Manuf Technol 68(5–8):1809–1820

Tzeng YF (2000) Process characterization of pulsed Nd:YAG laser seam welding. Int J Adv Manuf Technol 16(1):10–18

Paulraj S, Abdul Jaleel MY (2011) Influence of shielding gas mixtures on bead profile and micro structural characteristics of super austenitic stainless steel weldment by laser welding. Int J Adv Manuf Technol 54(5–8):525–535

Sun Z (1996) Feasibility of producing ferritic/ austenite dissimilar metal joints by high energy density laser beam process. Int Journal of pressure Vessels and piping 68(2):153–160

Tadamalle AP, Reddy YP, Ramjee E, Reddy KV Characterization and Optimization of Nd: YAG Laser Weld Joints of Dissimilar Metals, 5th International & 26th All India Manufacturing Technology, Design and Research Conference, AIMTDR 2014, Dec 12–14, 2014,IIT Guwahati, India, pp 80: 1–7. ISBN: 978–8–19274-612-8

Chunhua W, Jing Z, Shanglu Y, Wu T, Fengshun W, Weisheng X (2015) Experiment-based regional characterization of HAZ mechanical properties for laser welding. Int J Adv Manuf Technol 78(9–12):1629–1640

Tadamalle AP, Reddy YP, Ramjee E (2013) Influence of laser welding process parameters on weld pool geometry and duty cycle. International Journal of Advances in Production Engineering and Management 8(1):52–60

Lagneborg R (1991) New steels and steel applications for vehicles. Materials Design 12(1):3–14

Sun Z, Moisio T (1994) Melting ratio in laser welding of dissimilar metals. J Mater Sci Lett 13(13):980–982

Harish D, Somireddy A, Gururaj K (2012) A review on critical aspects of 316 in austenitic stainless steel weldability. International journal of material science and Applications 1(1):1–7

Klimpel A, Rzeznikiewicz A, Janik L (2010) Study of laser welding of copper, Journal of achievements in materials and manufacturing. Engineering 20(1–2):467–470

Honggang D, Wenjin H, Yuping D, Xudong W, Chuang D (2012) Dissimilar metal joining of aluminum alloy to galvanized steel with Al–Si, Al–Cu,Al–Si–Cu and Zn–Al filler wires. J Mater Process Technol 212:458–464

Tatushi H, Toshiyashu S, Chobin M, Kiyohiro M (2011) Joining of different melting point materials by changing with electromagnetic energy. Journal of solid Mechanics & materials engineering 3(4):662–666

Alexandre M, Rajashekar S, Alexis D, Michel S, Simone M, Dominique G, Eugen C (2007) Dissimilar material joining using laser. Optics & Laser Technology 39:652–661

Thaiping C, Wei-Bang L A study on dissimilar FSW process parameters in aluminum alloy and low carbon steel. International Conference on Smart Manufacturing Application, Korea, 2008: 9–14

Moraitis GA, Labeas GN (2008) Residual stress and distortion calculation of laser beam welding for aluminum lap joints. J Mater Process Technol 198:260–269

Ming-Liang Z, Fu-Zhen X (2010) Correlation between microstructure, hardness and strength in HAZ of dissimilar welds of rotor steels. Mater Sci Eng A 527:4035–4042

Long C, Longzao Z, Chao T, Wei H, Chunming W, Xiyuan H, Jun W, Fei Y, Xuefang W, Zhengguang J (2014) Study of laser butt welding of SUS301L stainless steel and welding joint analysis. Int J Adv Manuf Technol 73(9–12):1695–1704

Hui-Chi C, Andrew JP, Lin L (2011) Fiber laser welding of dissimilar alloys of Ti-6Al-4 V and Inconel 718 for aerospace applications. Int J Adv Manuf Technol 52(9–12):977–987

Bonnolo F, Tiziani A, Volpone LM (2004) Super austenitic stainless steel: the microstructure and fatigue strength a welded joints. Welding institute 18:24–30

David SA, Vitek JM (1981) Laser in metallurgy. In: Conference proceedings of the metallurgical society of ASME, 147–150

Monshi A, Reza Foroughi M, Reza Monshi M (2012) Modified Scherrer equation to estimate more accurately Nano-crystallite size using XRD. World Journal of Nano Science and Engineering 2:154–160. doi:10.4236/wjnse.2012.23020

Heino S, Kuntson Wedel EM, Karlson B (1999) Precipitation behavior in heat affected zone of welded super austenitic stainless steel. Material Science Technology 15:101–108

Torkamany MJ, Sabbaghzadeh J, Hamedi MJ (2012) Effect of laser welding mode on microstructure and mechanical performance of dissimilar laser spot welds between low carbon steels and austenitic stainless steels. Mater Des:666–672

Anawa EM, Olabi AG (2008) Optimization of tensile strength of ferritic/ austenitic laser welded components. Opt Laser Technol 40:379–386

Sathiya P, Mahendar KM, Shanmugarajan B (2012) Effect of shielding gases on microstructure and mechanical properties of super austenitic stainless steel by hybrid welding. Mater Des 33:203–212

Norris JT, Perricone MJ (2007) Pulse shaping effects on weld porosity in laser beam spot welds: contrast of long and short pulse welds; Sandia National Laboratories, Albuquerque K. M. Faraone, C. M. Ellison; Honeywell FM&T, Kansas City SANDIA REPORT SAND2007–6269, Unlimited Release, Printed October 2007

Soumitra Kumar Dinda A, Warnett Jason M, Mark B, Williams B, Gour Gopal Roy A, Srirangam P (2016) 3D imaging and quantification of porosity in electron beam welded dissimilar steel to Fe-Al alloy joints by X-ray tomography. Mater Des 96:224–231

Wei M, Huguo L, Fenggui L, Yixiong W, Jianhong C, Seiji Katayamaca Shanghai (2014) Porosity formation mechanism and its prevention in laser lap welding for T-joints. J Mater Process Technol 214:1658–1664

Ma J, Kong F, Kovacevic R (2012) Finite-element thermal analysis of laser welding of galvanized high-strength steel in a zero-gap lap joint configuration and its experimental verification. Mater Des 36:348–358

Schmidt M, Otto A, Kageler C (2008) Analysis of lap welding of zinc coated steel sheets, CIRP annuals- manufacturing. Technology 57:213–216

Yangyang Z, Yansong Z, Wei HXL (2012) Optimization of laser welding thin gage galvanized steel via response surface methodology. Opt Lasers Eng 50:1267–1273

Amrei MM, Monajati H, Yerreman V, Germain L, Bocher P (2016) Microstructure characterization and hardness distribution of 14Cr4Ni multipass weld metal. Mater Charact 111:128–136

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tadamalle, A.P., Reddy, Y.P., Ramjee, E. et al. Characterization of stainless steel and galvanized iron 0.5 mm thick laser weld joints. Int J Adv Manuf Technol 90, 383–395 (2017). https://doi.org/10.1007/s00170-016-9364-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9364-z