Abstract

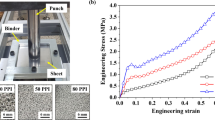

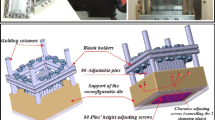

The technology of flexible blank holder (FBH) in multi-point forming (MPF) is a novel forming process for spherical surface parts, which is proposed based on the flexible method. According to the mechanical characteristics of the forming parts as well as the stress and strain state, the forming parts with good quality are obtained by reasonable distribution of the blank holder block and different blank holder force (BHF) at different locations. An original rigid FBH device is designed. Finite element analysis models of flexible blank holder (FBH) and no blank holder (NBH) are established, spherical surface parts with different BHF are simulated and then acquired the optimal BHF. The results indicate that FBH forming technology can avoid wrinkling defects effectively, the stress and strain are smaller and distribute uniformly, sheet metal flow is more uniform, and thickness distribution is more reasonable. Finally, a series of experiments of 08Al and 1060 with different thickness are completed in MPF dies to confirm the feasibility and versatility of the FBH device.

Similar content being viewed by others

References

Chen FK, Liao YC (2002) An analysis of draw-wall wrinkling in a stamping die design. Int J Adv Manuf Technol 19(4):253–259

Cai ZY, Li MZ, Song XS (2003) Analysis and control of wrinkling in multi-point forming of sheet metal without blankholder. J Plast Eng

Cai ZY, Wang SH, Li MZ (2008) Numerical investigation of multi-point forming process for sheet metal: wrinkling, dimpling and springback. Int J Adv Manuf Technol 37(9-10):927–936

Yossifon S, Sweeney K, Ahmetoglu M, Altan T (1992) On the acceptable blank-holder force range in the deep-drawing process. J Mater Process Technol 33(1-2):175–194

Siegert K (1993) CNC-hydraulic multipoint blank-holder system for sheet metal forming presses. AnIL CIRP 42(1):319–322

Siegert K, Häussermann M, Haller D, Wagner S, Ziegler M (2000) Tendencies in presses and dies for sheet metal forming processes. J Mater Process Technol 98(2):259–264

Ahmetoglu MA, Coremans A, Kinzel GL, Altan T (1993) Improving drawability by using variable blank holder force and pressure in deep drawing of round and non-symmetric parts. J Mater Manuf 102:428–435

Yagami T, Manabe KI, Yang M, Koyama H (2004) Intelligent sheet stamping process using segment blankholder modules. J Mater Process Technol 155–156:2099–2105

Sun CZ, Chen GL, Lin ZQ (2005) Determining the optimum variable blank-holder forces using adaptive response surface methodology (ARSM). Int J Adv Manuf Technol 26(1-2):23–29

Fu WZ, Li MZ, Deng YS, Li XJ (2006) A research on the flexible blank-holder in multi-point forming press. J Plast Eng 13(2):32–35

Peng LF, Lai XM, Li MZ (2006) Transition surface design for blank holder in multi-point forming. Int J Mach Tools Manufacture 46(12):1336–1342

Sun G, Li MZ, Yan XP (2007) Study of blank-holder technology on multi-point forming of thin sheet metal. J Mater Process Technol 187–188(12):517–520

Sun G, Li MZ, Deng YS, Li XJ (2008) Analysis on flexible and rigid blank-holders technology applying on thin sheet metal in multi-point forming. Chinese J Mech Eng 44(5):147–151

Li LC, Li YT, Li MZ (2013) Comparison on flexible blank-drawer and blank-holder forming process for sheet metal. Journal of Mechanical Engineering 49(02)

Li MZ, Liu YH, Su SZ, Li GQ (1999) Multi-point forming: a flexible manufacturing method for a 3-d surface sheet. J Mater Process Technol 87(1–3):277–280

Liu CG, Li MZ, Fu WZ (2008) Principles and apparatus of multi-point forming for sheet metal. Int J Adv Manuf Technol 35(11):1227–1233

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Li, M. & Ju, F. Research on the process of flexible blank holder in multi-point forming for spherical surface parts. Int J Adv Manuf Technol 89, 2315–2322 (2017). https://doi.org/10.1007/s00170-016-9198-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9198-8