Abstract

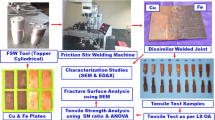

Tailor-welded blanks (TWBs) are considered one of the important manufacturing methods. By which, a single blank with multi-sheets with different thickness, material, surface conditions, grade, or strength is produced. In this paper, the formability of TWBs is investigated. The base metal used for this study is aluminum (Al-1050) with different thicknesses. A several thicknesses of base metal for instance 0.6, 0.8, 1.0, and 1.2 mm are combined. A different thickness ratio (TR) of sheets combination of TWBs i.e., 1.25, 1.33, and 1.5 is considered. The TWBs are welded using friction stir welding (FSW) technique. A different working condition for instance rotational speed and travel speed is used in this investigation. The TWBs specimens are drawn into flangeless cups. The limiting thickness ratio (LTR) and mechanical properties of base metals are determined. Several experiments are carried out to investigate the optimal working conditions. The experimental results are discussed and presented. A validation of the experimental results using Tagushi approach to verify the optimal welding parameters is presented.

Similar content being viewed by others

References

Merklein M, Johannes M, Lechner M, Kuppert A (2014) A review on tailored blanks—production, applications and evaluation. J Mater Process Technol 214:151–164

Panda SK, Kumar DR (2008) Improvement in formability of tailor welded blanks by application of counter pressure in biaxial stretch forming. J Mater Process Technol 204:70–79

W. M. Thomas, S. W. Kallee, D. G. Staines and P. J. Oakley (2006) Friction stir welding—process variants and developments in the automotive industry, in SAE World Congress

Morishita Y, Kado T, Abe S, Sakamoto Y, Yoshida F (2012) Role of counterpunch for square-cup drawing of tailored blank composed of thick/thin sheets. J Mater Process Technol 212:2102–2108

Cheng CH, Chan LC, Chow CL (2007) Weldment properties evaluation and formability study of tailor-welded blanks of different thickness combinations and welding orientations. J Mater Sci 42:5982–5990

Mishra R, Ma Z (2005) Friction stir welding and processing. Mater Sci Eng 50:1–78

Garware M, Kridli GT, Mallick PK (2010) Tensile and fatigue behavior of friction-stir welded tailor-welded blank of aluminum alloy 5754. JMEPEG 19:1161–1171

Mohanty HK, Venkateswarlu D, Mahapatra MM, Kumar P, Mandal NR (2012) Modeling the effects of tool probe geometries and process parameters on friction stirred aluminum welds. J Mech Eng Autom 2(4):74–79

Leitão C, Emílio B, Chaparro BM, Rodrigues DM (2009) Formability of similar and dissimilar friction stir welded AA 5182-H111 and AA 6016-T4 tailored blanks. Mater Des 30:3235–3242

He X, Gu F, Ball A (2014) A review of numerical analysis of friction stir welding. Prog Mater Sci 65:1–66

Tian H, Liu X, Lin J, Smith LM (2010) Investigation on the formability of tailor welded blanks with curved seams. Adv Mater Res 83-86:1160–1164 . doi:10.4028/www.scientific.net/AMR.83-86.1160© (2010) Trans Tech Publications, Switzerland

Tian H, Liu X, Lin J (2010) Investigation on the formability of tailor-welded blanks. Adv Mater Res 97-101:260–263 . doi:10.4028/www.scientific.net/AMR.97-101.260© (2010) Trans Tech Publications, Switzerland

Köklü U (2013) Investigation into the formability of Al-1050 tailor-welded blanks with antilock braking system. Int J Adv Manuf Technol 66:221–229. doi:10.1007/s00170-012-4320-z

Ma X, Guan Y (2016) Theoretical prediction and experimental investigation on formability of tailor-welded blanks. Trans Nonferrous Metals Soc China 26:228–236

Korouyeh RS, Naeini HM, Torkamany MJ, Liaghat G (2013) Experimental and theoretical investigation of thickness ratio effect on the formability of tailor welded blank. Opt Laser Technol 51:24–31

Kinsey BL, Wu X (2011) Tailor welded blanks for advanced manufacturing. Woodhead Publishing Limited, Beni-Suef, Egypt

Abdel-Magied, R. K., Wifi, A. S., Gomaa, A. H. (2003) A rule-based process planning system for axi-symmetrical deep drawing process. In Proceedings of AMPT2003, Dublin, Ireland, 8–11 July, 2003 (pp 462–465)

Taguchi G (1990) Introduction to quality engineering. Asian Productivity Organization, Tokyo

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdullah, M.E., Abdel-Magied, R.K. & Elsheikh, M.N. Experimental investigation of formability of Al-1050 tailor-welded blanks. Int J Adv Manuf Technol 89, 791–801 (2017). https://doi.org/10.1007/s00170-016-9147-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9147-6