Abstract

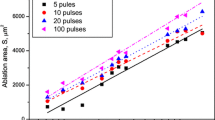

This study proposes an approach for determining the lateral displacement distance between adjacent scanning paths for femtosecond laser ablation of a uniform crater profile on stainless steel with a controllable ablation depth. The first step performs the ablation experiment and measures the ablation depth. The second step calculates the laser intensity accumulation factor according to different lateral displacement distances. The required lateral displacement distance needed to achieve the design ablation depth can be obtained based on the experimental data.

Similar content being viewed by others

References

Teixidor D, Orozco F, Thepsonthi T, Ciurana J, Rodríguez CA, Özel T (2013) Effect of process parameters in nanosecond pulsed laser micromachining of PMMA-based microchannels at near-infrared and ultraviolet wavelengths. Int J Adv Manuf Technol 67:1651–1664

Criales LE, Orozco PF, Medrano A, Rodríguez CA, Özel T (2015) Effect of fluence and pulse overlapping on fabrication of microchannels in PMMA/PDMS via UV laser micromachining: modeling and experimentation. Mater Manuf Process 30:890–901

Nolte S, Momma C, Jacobs H, Tunnermann A, Chichkov BN, Wellegehausen B, Welling H (1997) Ablation of metals by ultrashort laser pulses. J Opt Soc Am B Opt Phys 14:2716–2722

Qi LT, Nishii K, Namba Y (2009) Regular subwavelength surface structures induced by femtosecond laser pulses on stainless steel. Opt Lett 34:1846–1848

Nayak BK, Gupta MC (2010) Self-organized micro/nano structures in metal surfaces by ultrafast laser irradiation. Opt Lasers Eng 48:940–949

M. Martínez-Calderon, A. Rodríguez, A. Dias-Ponte, M.C. Morant-Miñana, M. Gómez-Aranzadi, S.M. Olaizola, Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Appl Surf Sci

Ling EJY, Saïd J, Brodusch N, Gauvin R, Servio P, Kietzig A-M (2015) Investigating and understanding the effects of multiple femtosecond laser scans on the surface topography of stainless steel 304 and titanium. Appl Surf Sci 353:512–521

Liu B, Jiang G, Wang W, Mei X, Wang K, Cui J, Wang J (2016) Porous microstructures induced by picosecond laser scanning irradiation on stainless steel surface. Opt Lasers Eng 78:55–63

M. Weikert, C. Foehl, F. Dausinger (2003) Surface structuring of metals with ultrashort laser pulses, in. pp. 501–505

Mannion PT, Magee J, Coyne E, O'Connor GM, Glynn TJ (2004) The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl Surf Sci 233:275–287

Le Harzic R, Breitling D, Weikert M, Sommer S, Fohl C, Valette S, Donnet C, Audouard E, Dausinger F (2005) Pulse width and energy influence on laser micromachining of metals in a range of 100 f. to 5 ps. Appl Surf Sci 249:322–331

Cheng J, Perrie W, Edwardson SP, Fearon E, Dearden G, Watkins KG (2009) Effects of laser operating parameters on metals micromachining with ultrafast lasers. Appl Surf Sci 256:1514–1520

Park C, Farson DF (2015) Precise machining of disk shapes from thick metal substrates by femtosecond laser ablation. Int J Adv Manuf Technol 83:2049–2056, 1-8

Heyl P, Olschewski T, Wijnaendts RW (2001) Manufacturing of 3D structures for micro-tools using laser ablation. Microelectron Eng 57–58:775–780

Rodríguez A, Arriola A, Tavera T, Pérez N, Olaizola SM (2012) Enhanced depth control of ultrafast laser micromachining of microchannels in soda-lime glass. Microelectron Eng 98:672–675

Pfeiffer M, Engel A, Weißmantel S, Scholze S, Reisse G (2011) Microstructuring of steel and hard metal using femtosecond laser pulses. Phys Proc 12:60–66, Part B

Bruneel D, Matras G, Le Harzic R, Huot N, Koenig K, Audouard E (2010) Micromachining of metals with ultra-short Ti-Sapphire lasers: prediction and optimization of the processing time. Opt Lasers Eng 48:268–271

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, CW., Tsai, XZ. & Chen, JS. Micromachining of stainless steel with controllable ablation depth using femtosecond laser pulses. Int J Adv Manuf Technol 85, 1947–1954 (2016). https://doi.org/10.1007/s00170-016-8821-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8821-z