Abstract

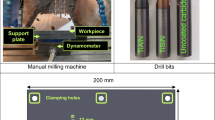

Machining experiments were conducted to evaluate the impact of cutting parameters on the hole quality and cutting forces in drilling Al2024-T3 aerospace alloy. Al2024-T3 specimen were drilled using Φ6-mm TiAlN-coated carbide twist drills under dry cutting conditions. The hole quality was inspected in terms of its surface roughness, burr and chip formations, hole size, circularity error and post-machining microhardness of the subsurface of the holes. An analysis of variance (ANOVA) was carried out to determine the percentage contribution of cutting parameters on cutting forces and the inspected hole quality parameters. A three-dimensional (3D) finite element (FE) model of drilling Al2024-T3 is developed using Abaqus/Explicit to predict thrust force and torque. The FE model was validated using experimental results and found to be in good agreement. The results of the study showed that the cutting parameters have a significant impact on cutting forces and inspected hole quality parameters. Drilling at feed rates of 100 and 300 mm/min and spindle speeds of 1000, 3000, and 6000 rpm are recommended for producing holes with smaller surface roughness, deviation from nominal hole size, circularity error and burrs.

Similar content being viewed by others

References

Farid AA, Sharif S, Idris MH (2011) Chip morphology study in high speed drilling of Al–Si alloy. Int J Adv Manuf Technol 57(5–8):555–564

Carter Ralph W, Steven Johnson W, Toivonen P, Makeev A, Newman JC Jr (2006) Effect of various aircraft production drilling procedures on hole quality. Int J Fatigue 28(8):943–950

Shop MM (2010) Presetting process cuts scrap, rework. Modern machine shop, Modern machine shop

Hashimura M, Chang Y, Dornfeld D (1999) Analysis of burr formation mechanism in orthogonal cutting. J Manuf Sci Eng 121(1):1–7

Nouari M, List G, Girot F, Coupard D (2003) Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 255(7):1359–1368

Fang N, Wu Q (2005) The effects of chamfered and honed tool edge geometry in machining of three aluminum alloys. Int J Mach Tools Manuf 45(10):1178–1187

Shareef I, Natarajan M, Ajayi OO (2005) Dry machinability of aluminum alloys. In: World tribology congress III. American Society of Mechanical Engineers pp 831–832

Dhanorker A, Özel TR (2006) An experimental and modeling study on meso/micro end milling process. In: ASME 2006 International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, pp 1071–1079

Chern G-L (2006) Experimental observation and analysis of burr formation mechanisms in face milling of aluminum alloys. Int J Mach Tools Manuf 46(12–13):1517–1525

Subbiah S, Melkote SN (2008) Effect of finite edge radius on ductile fracture ahead of the cutting tool edge in micro-cutting of Al2024-T3. Mater Sci Eng A 474(1–2):283–300

Adnan AS, Subbiah S (2010) Experimental investigation of transverse vibration-assisted orthogonal cutting of AL-2024. Int J Mach Tools Manuf 50(3):294–302

Haddag B, Atlati S, Nouari M, Barlier C, Zenasni M (2012) Analysis of the cutting parameters influence during machining aluminium alloy A2024-T351 with uncoated carbide inserts. Eng Trans 60(1):31–39

Mohamed SB, Mohamad WNF, Minhat M, Kasim MS, Ibrahim Z, Musanih MR (2015) Machining parameters optimization for trimming operation in a milling machine using two level factorial design. In: Applied mechanics and materials. Trans Tech Publications pp 105–110

Çakır A, Yağmur S, Kavak N, Küçüktürk G, Şeker U (2015) The effect of minimum quantity lubrication under different parameters in the turning of AA7075 and AA2024 aluminium alloys. Int J Adv Manuf Technol 1–7

Nouari M, List G, Girot F, Géhin D (2005) Effect of machining parameters and coating on wear mechanisms in dry drilling of aluminium alloys. Int J Mach Tools Manuf 45(12–13):1436–1442

Kurt M, Bagci E, Kaynak Y (2009) Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes. Int J Adv Manuf Technol 40(5–6):458–469

Kurt M, Kaynak Y, Bagci E (2008) Evaluation of drilled hole quality in Al 2024 alloy. Int J Adv Manuf Technol 37(11):1051–1060

Köklü U (2012) Influence of the process parameters and the mechanical properties of aluminum alloys on the burr height and the surface roughness in dry drilling. Materiali Tehnologije 46(2):103–108

Davoudinejad A, Ashrafi SA, Hamzah RIR, Niazi A (2012) Experimental analysis of wear mechanism and tool life in dry drilling of Al2024. In: Advanced materials research. Trans Tech Publ pp 217–221

Amini S, Paktinat H, Barani A, Tehran AF (2013) Vibration drilling of Al2024-T6. Mater Manuf Process 28(4):476–480

Mohamed Elajrami HMaFBB (2013) Effect of drilling parameters on hole quality. Int J Min Metall Mech Eng 1 (4):254–257

Barani A, Amini S, Paktinat H, Tehrani AF (2014) Built-up edge investigation in vibration drilling of Al2024-T6. Ultrasonics 54(5):1300–1310

Abdelhafeez AM, Soo SL, Aspinwall DK, Dowson A, Arnold D (2015) Burr formation and hole quality when drilling titanium and aluminium alloys. Procedia CIRP 37:230–235

Barani A, Amini S, Paktinat H, Fadaei Tehrani A (2014) Built-up edge investigation in vibration drilling of Al2024-T6. Ultrasonics 54(5):1300–1310

Davim JP (2011) Modern machining technology: a practical guide. Elsevier

Ko S-L, Lee J-K (2001) Analysis of burr formation in drilling with a new-concept drill. J Mater Process Technol 113(1–3):392–398. doi:10.1016/s0924-0136(01)00717-8

Dandekar C, Orady E, Mallick PK (2007) Drilling characteristics of an E-glass fabric-reinforced polypropylene composite and an aluminum alloy: a comparative study. J Manuf Sci Eng 129(6):1080–1087

Batzer S, Haan D, Rao P, Olson W, Sutherland J (1998) Chip morphology and hole surface texture in the drilling of cast aluminum alloys. J Mater Process Technol 79(1):72–78

Isbilir O, Ghassemieh E (2011) Finite element analysis of drilling of titanium alloy. Procedia Eng 10:1877–1882

Soo S, Aspinwall D, Dewes R (2004) 3D FE modelling of the cutting of Inconel 718. J Mater Process Technol 150(1):116–123

Mabrouki T, Rigal J-F (2006) A contribution to a qualitative understanding of thermo-mechanical effects during chip formation in hard turning. J Mater Process Technol 176(1):214–221

Chang C-S (2007) Prediction of the cutting temperatures of stainless steel with chamfered main cutting edge tools. J Mater Process Technol 190(1):332–341

Hortig C, Svendsen B (2007) Simulation of chip formation during high-speed cutting. J Mater Process Technol 186(1):66–76

Hua J, Shivpuri R (2004) Prediction of chip morphology and segmentation during the machining of titanium alloys. J Mater Process Technol 150(1):124–133

Jeevannavar A, Hussain R (2014) Process modelling, simulation and experimental validation for prediction of chip morphology during high speed machining of Al 2024-T3. SAS TECH J 13(1):72–80

Asad M, Girardin F, Mabrouki T, Rigal J-F (2008) Dry cutting study of an aluminium alloy (A2024-T351): a numerical and experimental approach. Int J Mater Form 1(1):499–502

Akram S, Jaffery SHI, Khan M, Mubashar A, Ali L A numerical investigation of effects of cutting velocity and feed rate on residual stresses in aluminum alloy Al-6061

Shi G, Deng X, Shet C (2002) A finite element study of the effect of friction in orthogonal metal cutting. Finite Elem Anal Des 38(9):863–883

Hazarika M, Dixit US (2014) Setup planning for machining. Springer International Publishing

Shanmughasundaram P, Subramanian R (2014) Study of parametric optimization of burr formation in step drilling of eutectic Al–Si alloy–Gr composites. J Mater Res Technol 3(2):150–157

Stephenson DA, Agapiou JS (2005) Metal cutting theory and practice, vol 68. CRC press

Toenshoff HK, Denkena B (2013) Basics of cutting and abrasive processes. Springer

Version A 6.13 Documentation (Abaqus), 2013. Abaqus user’s guide

Lesuer DR (1999) Experimental investigations of material models for Ti-6A1-4V and 2024-T3 University of California, Lawrence Livermore National Laboratory, Livermore

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the 7th International Symposium on Ballistics. The Hague, Netherlands: International Ballistics Committee, pp 541–547

Mabrouki T, Girardin F, Asad M, Rigal J-F (2008) Numerical and experimental study of dry cutting for an aeronautic aluminium alloy (A2024-T351). Int J Mach Tools Manuf 48(11):1187–1197

Straffelini G (2015) Friction and wear: methodologies for design and control. Springer International Publishing

Cheng K (2008) Machining dynamics: fundamentals, applications and practices. Springer Science & Business Media

Rao PN (2013) Manufacturing technology: metal cutting and machine tools. v. 2. Tata McGraw-Hill Education

Qin Y (2015) Micromanufacturing engineering and technology. Elsevier Science

Oberg E (2012) Machinery’s handbook 29th edition-full book. Industrial Press

Jin X (2012) Mechanics and dynamics of micro-cutting process. Ph.D, The University of British Columbia-Vancouver

Seshadri R, Naveen I, Srinivasan S, Viswasubrahmanyam M, VijaySekar K, Kumar MP (2013) Finite element simulation of the orthogonal machining process with Al 2024 T351 aerospace alloy. Procedia Eng 64:1454–1463

Yang K, Liang Y-C, Zheng K-N, Bai Q-S, Chen W-Q (2011) Tool edge radius effect on cutting temperature in micro-end-milling process. Int J Adv Manuf Technol 52(9–12):905–912

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Giasin, K., Hodzic, A., Phadnis, V. et al. Assessment of cutting forces and hole quality in drilling Al2024 aluminium alloy: experimental and finite element study. Int J Adv Manuf Technol 87, 2041–2061 (2016). https://doi.org/10.1007/s00170-016-8563-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8563-y