Abstract

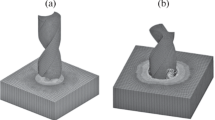

Chip formation during drilling operation is greatly influenced by the cutting parameters such as cutting speed, feed rate, and drill geometry. However, not many studies have focused on the direct observation of the chip formation during high speed drilling. This paper investigates the effect of cutting speed and feed rate on the chip morphology during high speed drilling of aluminum–silicon alloys using carbide drill. Observation on the multiview characterization of the chips was carried out which includes free surface, back surface, and cross-section of top surface. Structure and shape alterations of the free and back surfaces were analyzed using a scanning electron microscope. Finally, different geometrical parameters of chip cross-section were measured in order to study the effect of cutting parameters on chip compression ratio and thrust force. It was found that increase in cutting speed significantly affects the chip morphology especially on the structure of free surface and cross-section of the chips. Results also showed that built-up edge on the rake face of tool played an important role on the formation of irregular pattern on the chip back surface.

Similar content being viewed by others

References

Batzer SA, Haan DM, Rao PD, Olson WW, Sutherland JW (1998) Chip morphology and hole surface texture in the drilling of cast Aluminum alloys. J Mater Process Technol 79:72–78

Degenhar JA, DeVor RE, Kapoor SG (2005) Generalized groove-type chip breaker effects on drilling for different drill diameters and flute shapes. Int J Mach Tools Manuf 45:1588–1597

Hoshi T, Zhao H (1989) Study of high performance drill geometry. CIRP Ann Manuf Technol 38(1):87–90

Komanduri R, Flom DG, Lee M (1985) Highlights of the DARPA advanced machining research program. J Eng Ind 107:325–335

Flom DG (1984) Implementation of high speed machining. High Speed Machining, ASME, New York

Kishawy HA, Dumitrescu M, Ng EG, Elbestawi MA (2005) Effect of coolant strategy on tool performance, chip morphology and surface quality during high-speed machining of A356 aluminum alloy. Int J Mach Tools Manuf 45:219–227

Recht RF (1964) Catastrophic thermoplastic shear. J Appl Mech Trans ASME 31E:189–193

Müller C, Blümke R (2001) Influence of heat treatment and cutting speed on chip segmentation of age hardenable aluminium alloy. Mater Sci Technol 17:651–654

Barry J, Byrne G (2002) The mechanisms of chip formation in machining hardened steels. J Manuf Sci Eng Trans ASME 124:528–535

Black JT (1971) On the fundamental mechanism of large strain plastic deformation (electron microscopy of metal cutting chips). ASME J Eng Ind 93:507–526

Shaw MC (1980) A new mechanism of plastic flow. Int J Mech Sci 22:673–686

van Luttervelt CA (1977) Split shearzone—mechanism of chip segmentation. Manuf Technol, Gen Assem of CIRP, 27th 26: 33–38

Barry J, Byrne G (2002) Chip formation, acoustic emission and surface white layers in hard machining. CIRP Ann Manuf Technol 51:65–70

Barry J, Byrne G (2001) Study on acoustic emission in machining hardened steels: Part 2: acoustic emission during continuous chip formation with a non-overlapping cutting arrangement. Proc Inst Mech Eng, B: J Eng Manuf 215:1561–1570

Sun J, Guo YB (2008) A new multi-view approach to characterize 3D chip morphology and properties in end milling titanium Ti-6Al-4 V. Int J Mach Tools Manuf 48:1486–1494

Trent EM, Wright PK (2000) Metal cutting, 4th ed. Butterworth–Heinemann, Massachusetts

Astakhov VP (2006) Tribology of metal cutting, 1st edn. Elsevier, London

Cook NH (1953) Chip formation in machining titanium. In: Proceedings of the Symposium on Machine Grind. Proc. Symp. on Machining and Grinding Titanium, Watertown Arsenal, MA:1–7

Talantov N (1984). Physical processes in the cutting of metals. Volgograd

Shaw MC, Vyas A (1993) Chip formation in the machining of hardened steel. CIRP Ann Manuf Technol 42:29–33

Astakhov VP (2010) Geometry of single-point turning tools and drills. Springer, London

Marusich TD (2001) Effects of friction and cutting speed on cutting force. Am Soc Mech Eng Manuf Eng Division Pages MED 12:115–123

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akhavan Farid, A., Sharif, S. & Idris, M.H. Chip morphology study in high speed drilling of Al–Si alloy. Int J Adv Manuf Technol 57, 555–564 (2011). https://doi.org/10.1007/s00170-011-3325-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3325-3