Abstract

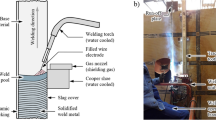

Lap joining of 6061 aluminum alloy (Al alloy) to 304 stainless steel (SS) by pulse on pulse metal inert gas (MIG) welding-brazing process using 4043 Al-Si filler wire was conducted to study the effect of pulse on pulse frequency on welding process and welding quality. The results show that for high-energy pulse, the effect of pulse on pulse frequency on arc characteristics and behavior of metal transfer is significant. However, for low-energy pulse, this effect is insignificant. The external oscillation frequency of the molten pool induced by variation of arc force and impingement of metal droplets is closer to its natural oscillation frequency when the pulse on pulse frequency is 5.3 Hz; the weld pool is more intensively oscillated. This phenomenon results in the formation of fine and uniform equiaxed grain structures, and thin brazed interface layers, which leads to excellent mechanical properties. The thickness of brazed interface layers varied from about 5 to 9 μm, and the thinner the layer, the better the mechanical properties of Al alloy/SS joints are. When pulse on pulse frequency is less than or equal to 5.3 Hz, the joints fractured at heat-affected zone of 6061 Al alloy with highest strength of 117.4 MPa up to 94.7 % of the tensile strength of Al alloy. However, the joints fractured at the brazed interface layer with much lower strength when the pulse on pulse frequency is larger than 5.3 Hz.

Similar content being viewed by others

References

Mahendran G, Balasubramanian V, Senthilvelan T (2009) Developing diffusion bonding windows for joining AZ31B magnesium and copper alloys. Int J Adv Manuf Technol 42:689–695

Elthalabawy WM, Khan TI (2011) Eutectic bonding of austenitic stainless steel 316L to magnesium alloy AZ31 using copper interlayer. Int J Adv Manuf Technol 55:235–241

Chen YB, Chen SH, Li LQ (2009) The effect of heat input on microstructure and mechanical property of Al/Ti joints by rectangular spot laser welding-brazing method. Int J Adv Manuf Technol 44:265–272

Mathieu A, Pontevicci S, Viala JC, Cicala E, Mattei S, Grevey D (2006) Laser brazing of a steel/aluminum assembly with hot filler metal. Mater Sci Eng A 435(436):19–28

Matsumura Y, Ogawa S, Misaki T (2008) Joining process of dissimilar metal for aluminum roof. Weld Int 22(2):73–76

Li YJ, Wang J, Liu Q (2006) Non-ferrous metal welding and application. Chemical Industry Press: 251-256

Crane CH, Lovell DT, Baginski WA, Olsen MG (1967) Diffusion welding of dissimilar metals. Weld J 46(1):21s–1s

Naimon ER, Doyle JH, Rice CR, Vigil D, Walmsley DR (1981) Diffusion welding of aluminum to stainless steel. Weld J 60(11):17–20

Karfoul M, Tatlock G, Murray R (2007) The behaviour of iron and aluminium during the diffusion welding of carbon steel to aluminium. J Mater Sci 42(14):5692–5699

Takemoto T, Okamoto I (1988) Intermetallic compounds formed during brazing of titanium with aluminium filler metals. J Mater Sci 23:1301–1308

AlHazaa A, Khan TI, Haq I (2010) Transient liquid phase (TLP) bonding of Al7075 to Ti–6Al–4V alloy. Mater Charact 61:312–317

Acarer M, Demir B (2008) An investigation of mechanical and metallurgical properties of explosive welded aluminum-dual phase steel. Mater Lett 62(25):4158–4160

Handa A, Chawla V (2014) Investigation of mechanical properties of friction-welded AISI 304 and AISI 1021 dissimilar steels. Int J Adv Manuf Technol 75:1493–1500

Arivazhagan N, Singh S, Prakash S, Reddy GM (2008) An assessment of hardness, impact strength and hot corrosion behavior of friction-welded dissimilar weldments between AISI 4140 and AISI304. Int J Adv Manuf Technol 39:679–689

Lee WB, Schmuecker W, Mercardo UA, Biallas G, Jung SB (2006) Interfacial reaction in steel-aluminum joints made by friction stir welding. Scripta Mater 55(4):355–358

Watanabe T, Takayama H, Yanagisawa A (2006) Joining of aluminum alloy to steel by friction stir welding. J Mater Process Technol 178(1–3):342–349

Park HJ, Rhee S, Kang MJ, Kim DC (2009) Joining of steel to aluminum alloy by AC pulse MIG welding. Mater Trans 50(9):2314–2317

Lin SB, Song JL, Yang CL, Ma GC (2009) Metallurgical and me2chanical investigations of aluminium-steel butt joint made by tungsten inert gas welding-brazing. Sci Technol Weld Join 14(7):636–639

Zhang HT, Liu JK (2011) Microstructure characteristics and mechanical property of aluminum alloy/stainless steel lap joints fabricated by MIG welding-brazing process. Mater Sci Eng A 528:6179–6185

Yagati KP, Bathe RN, Rajulapati KV, Rao KBS, Padmanabham G (2014) Fluxless arc weld-brazing of aluminium alloy to steel. J Mater Process Technol 214:2949–2959

Sierra G, Peyre P, Beaume FD, Stuart D, Fras G (2008) Galvanised steel to aluminium joining by laser and GTAW processes. Mater Charact 59(12):1705–1715

Bacha FW, Beniyashb A, Lauc K, Versemann R (2005) Joining of steel-aluminum hybrid structures with electron beam on atmosphere. Adv Mater Res 6(8):143–150

Tipi AD (2010) The study on the drop detachment for automatic pipeline GMAW system: free flight mode. Int J Adv Manuf Technol 50:137–147

Liu AH, Tang XH, Lu FG (2013) Arc profile characteristics of Al alloy in double-pulsed GMAW. Int J Adv Manuf Technol 65:1–7

Zhang ZD, Kong XY (2012) Study on DC double pulse metal inert gas (MIG) welding of magnesium alloy. Mater Manuf Process 27:462–466

Mendes da Silva CL, Scotti A (2006) The influence of double pulse on porosity formation in aluminum GMAW. J Mater Process Technol 171:366–372

Li JX, Li H, Wei HL, Gao Y (2015) Effect of torch position and angle on welding quality and welding process stability in pulse on pulse MIG welding-brazing of aluminum alloy to stainless steel. Int J Adv Manuf Technol. doi: 10.1007/s00170-015-7734-6

Li X, Lawson S, Zhou Y (2007) Novel technique for laser lap welding of zinc coated sheet steels. J Laser Appl 19:259–264

Peyre P, Sierra G, Deschaux-Beaume F, Stuart D, Fras G (2007) Generation of aluminum-steel joints with laser-induced reactive wetting. Mater Sci Eng A 444:327–338

Murakami T, Nakata K, Tong H (2003) Dissimilar metal joining of aluminum to steel by MIG arc brazing using flux cored wire. ISIJ Int 43(10):1596–1620

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, J., Li, H., Wei, H. et al. Effect of pulse on pulse frequency on welding process and welding quality of pulse on pulse MIG welding-brazing of aluminum alloys to stainless steel. Int J Adv Manuf Technol 87, 51–63 (2016). https://doi.org/10.1007/s00170-016-8369-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8369-y