Abstract

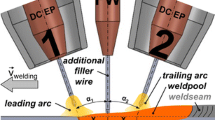

Arcing-wire gas tungsten arc welding is an innovative process developed as a variant of gas tungsten arc welding to reinforce the deposition rate by utilizing bypass arc energy. After establishing an experimental platform, the experiments were conducted to study the arc characteristics, interaction of the main and bypass arcs, and metal transfer behavior. Magnetic arc blow, location of the bypass arc root, and shielding gas flow were found to cause arc deflection and an invisible obstacle between the arcs in arcing-wire gas tungsten arc welding. The bypass arc voltage should be controlled carefully to maintain the stability of the welding process. Globular transfer, short-circuiting transfer, and continuous bridging transfer could be obtained, which were determined by wire feed speed (the melting current) and the distance from the wire tip to the workpiece as well as the welding direction.

Similar content being viewed by others

References

Moniz BJ, Miller RT (2010) Welding skill. American Technical Publisher

O’Brion RL (1991) Welding handbook. Welding Process. American Welding Society, Miami

Alexander CK, Sadiku MNO (2000) Fundamentals of electric circuits. McGraw Hill

Chen JS, Lu Y, Li XR, Zhang YM (2012) Gas tungsten arc welding using an arcing wire. Weld J 91:261s–269s

Lv SX, Tian XB, Wang HT, Yang SQ (2007) Arcing heating hot wire assisted arc welding technology for low resistance welding wire. Sci Technol Weld Join 12:431–435

Lu Y, Chen SJ, Shi Y, Li XR, Chen JS, Kvidahl L, Zhang YM (2014) Double-electrode arc welding process: principle, variants, control and developments. J Manuf Process 16:93–108

Kah P, Suoranta R, Martikainen J (2013) Advanced gas metal arc welding processes. Int J Adv Manuf Technol 67:655–674

Doodman Tipi AR, Hosseini sani SK, Pariz N (2015) Improving the dynamic metal transfer model of gas metal arc welding (GMAW) process. Int J Adv Manuf Technol 76:657–668

Li KH, Zhang YM (2010) Interval model control of consumable double-electrode gas metal arc welding process. IEEE Trans Autom Sci Eng 7:826–839

Li KH, Zhang YM (2007) Metal transfer in double-electrode gas metal arc welding. J Manuf Sci Eng 129:991–999

Li KH, Zhang YM, Xu P, Yang FQ (2008) High-strength steel welding with consumable double-electrode gas metal arc welding. Weld J 87:57–64

Zhang W, Hua XM, Liao W, Li F, Wang M (2014) Behavior of the plasma characteristic and droplet transfer in CO2 laser–GMAW-P hybrid welding. Int J Adv Manuf Technol 72:935–942

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Hu, S., Wang, Z. et al. Arc characteristics and metal transfer modes in arcing-wire gas tungsten arc welding. Int J Adv Manuf Technol 86, 925–933 (2016). https://doi.org/10.1007/s00170-015-8228-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8228-2