Abstract

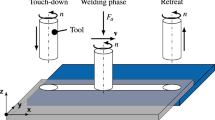

Friction stir welding (FSW) is a promising welding technology and is being extensively researched because it can produce high-quality joints. In the welding process, due to improper clamping, deformation of back support and other process variations, the axial force can vary significantly and produce welding defects. To solve this problem, a feedback controller of FSW axial force is desirable. However, time-delay, which widely exists within the FSW systems, may degrade the controller effect and make the system unstable. To regulate the axial force and compensate the time delay, this paper designs an axial force controller for FSW system with delay. At first, by utilizing a time delay compensation scheme, FSW systems with delayed control actions is transformed into standard differential equations without time delay terms. Then, an axial force controller is designed based on the linear-quadratic regulator (LQR) technique. Since the time delay is incorporated in the system model throughout the whole controller design process, the system performance and stability are assured and the control system is also simplified. Utilizing the LQR technique, aspects of system dynamic properties and simplicity are considered simultaneously. Experimental validations were carried out on a FSW platform. The experimental results demonstrate that the time delay is compensated effectively. The controller maintains the constant axial force and shows desirable dynamic behavior, even when the disturbance is encountered during the welding process.

Similar content being viewed by others

References

Thomas WM, Nicholas ED, Needham JC, Murch MG, Temple-Smith P, Dawes CJ (1991) Friction stir butt welding. GB patent no. 9125978.8

Heidarzadeh A, Saeid T (2013) Prediction of mechanical properties in friction stir welds of pure copper. Mater Des 52:1077–1087

Ye F, Fujii H, Tsumura T, Nakata K (2006) Friction stir welding of Inconel alloy 600. J Mater Sci 41(16):5376–5379

Rajakumar S, Muralidharan C, Balasubramanian V (2011) Influence of friction stir welding process and tool parameters on strength properties of AA7075-T6 aluminum alloy joints. Mater Des 32(2):535–549

Rose AR, Manisekar K, Balasubramanian V (2011) Effect of axial force on microstructure and tensile properties of friction stir welded AZ61A magnesium alloy. Trans Nonferrous Metals Soc China 21(5):974–984

Rajakumar S, Balasubramanian V (2012) Establishing relationships between mechanical properties of aluminium alloys and optimised friction stir welding process parameters. Mater Des 40:17–35

Longhurst WR, Strauss AM, Cook GE, Fleming P (2010) Torque control of friction stir welding for manufacturing and automation. Int J Adv Manuf Technol 51(9):905–913

Davis TA, Ngo PD, Shin YC (2012) Multi-level fuzzy control of friction stir welding power. Int J Adv Manuf Technol 59:559–567

Backer JD, Bolmsjö G, Christiansson AK (2014) Temperature control of robotic friction stir welding using the thermoelectric effect. Int J Adv Manuf Technol 70:375–383

Rajashekar R, Rajaprakash BM (2016) Development of a model for friction stir weld quality assessment using machine vision and acoustic emission techniques. J Mater Process Technol 229:265–274

Prater T, Gibson B, Cox C, Cook GE, Strauss A, Longhurst W (2015) Evaluation of torque as a means of in-process sensing of tool wear in friction stir welding of metal matrix composites. Ind Robot 42(3):192–199

Senthilraja R, Naveen Sait A (2015) Modeling and parametric optimization of friction stir welding for magnesium AZ91D alloys using factorial design. Int J Appl Eng Res 10(4):10253–10264

Fehrenbacher A, Duffie NA, Ferrier NJ, Pfefferkorn FE, Zinn MR (2014) Effects of tool-workpiece interface temperature on weld quality and quality improvements through temperature control in friction stir welding. Int J Adv Manuf Technol 71(1–4):165–179

Lakshminarayanan AK, Balasubramanian V (2008) Process parameters optimization for friction stir welding of RDE-40 aluminium alloy using Taguchi technique. Trans Nonferrous Metals Soc China (Engl Ed) 18(3):548–554

Balaji S, Mahapatra MM (2013) Experimental study and modeling of friction stir welding process to produce optimized AA2219 butt welds for aerospace application. Proc Inst Mech Eng B J Eng Manuf 227(1):132–143

Zäh MF, Eireiner D (2004) Friction stir welding using NC milling machines. Weld Cut 56(4):220–223

Cook GE, Smartt HB, Mitchell JE, Strauss AM, Crawford R (2003) Controlling robotic friction stir welding. Weld J 82(6):28–34

Shi J, Wang YH, Zhang G, Ding H (2013) Optimal design of 3-DOF PKM module for friction stir welding. Int J Adv Manuf Technol 66:1879–1889

Longhurst WR, Strauss AM, Cook GE, Cox CD, Hendricks CE, Gibson BT, Dawant YS (2010) Investigation of force-controlled friction stir welding for manufacturing and automation. Proc Inst Mech Eng B J Eng Manuf 224(6):937–949

Smith C (2004) Robotic friction stir welding using a standard industrial robot, Kei Kinzoku Yosetsu. J Light Metals Weld Construction 42(3):40–41

Von Strombeck A, Schilling C, Dos Santos JF (2000) Robotic Friction Stir welding: tool, technology and applications. Proceedings of the Second International Symposium of Friction Stir Welding, Gotherburg, pp 26–28

Zhao X, Kalya P, Landers RG, Krishnamurthy K (2008) Design and implementation of nonlinear force controllers for friction stir welding processes. J Manuf Sci Eng 130(6):0610111–06101110

Oakes T, Landers RG (2009) Design and implementation of a general tracking controller for friction stir welding processes. Proceedings of the American Control Conference, St. Louis, pp 5576–5581

Davis TA, Shin YC, Yao B (2011) Observer-based adaptive robust control of friction stir welding axial force. IEEE/ASME Trans Mech 16(6):1032–1039

Fehrenbacher A, Smith CB, Duffie NA, Ferrier NJ, Pfefferkorn FE, Zinn MR (2014) Combined temperature and force control for robotic friction stir welding. J Manuf Sci Eng 136(2):21007

Sua H, Wu CS, Bachmann M, Rethmeier M (2015) Numerical modeling for the effect of pin profiles on thermal and material flow characteristics in friction stir welding. Mater Des 77:114–125

Zhao X, Kalya P, Landers RG, Krishnamurthy K (2009) Empirical dynamic modeling of friction stir welding processes. J Manuf Sci Eng 131(2):0210011–0210019

Fathi A, Khajepour A, Durali M, Toyserkani E (2008) Geometry control of the deposited layer in a nonplanar laser cladding process using a variable structure controller. J Manuf Sci Eng 130(3):031003

Artstein Z (1982) Linear systems with delayed controls: a compensation. Autom Control 27(4):869–879

Du J (2008) The basis of control engineering. Tsinghua University Press, Beijing

Zhao G (2009) Modern control theory. Chinese Machine Press, Beijing

Choi JW, Seo YB (1999) LQR design with eigenstructure assignment capability [and application to aircraft flight control]. Aerosp Electron Syst 35(2):700–708

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, S., Bi, Q. & Wang, Y. An axial force controller with delay compensation for the friction stir welding process. Int J Adv Manuf Technol 85, 2623–2638 (2016). https://doi.org/10.1007/s00170-015-8096-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8096-9