Abstract

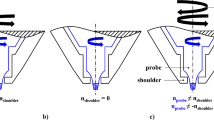

Friction stir welding (FSW) is a solid-state welding process that utilizes a rotating tool to plastically deform and forge together the parent materials of a workpiece. The process involves plunging the rotating tool that consists of a shoulder and a pin into the workpiece and then traversing it along the intended weld seam. The welding process requires a large axial force to be maintained on the tool. Axial force control has been used in robotic FSW processes to compensate for the compliant nature of robots. Without force control, welding flaws would continuously emerge as the robot repositioned its linkages to traverse the tool along the intended weld seam. Insufficient plunge depth would result and cause the welding flaws as the robot’s linkages yielded from the resulting force in the welding environment. The research present in this paper investigates the use of torque instead of force to control the FSW process. To perform this research, a torque controller was implemented on a retrofitted Milwaukee Model K milling machine. The closed loop proportional, integral plus derivative control architecture was tuned using the Ziegler–Nichols method. Welding experiments were conducted by butt welding 0.25 in. (6.35 mm) × 1.5 in. (38.1 mm) × 8 in. (203.2 mm) samples of aluminum 6061 with a 0.25 in. (6.35 mm) threaded tool. The results indicate that controlling torque produces an acceptable weld process that adapts to the changing surface conditions of the workpiece. For this experiment, the torque was able to be controlled with standard deviation of 0.231 N-m. In addition, the torque controller was able to adjust the tool’s plunge depth in reaction to 1 mm step and ramp disturbances in the workpiece’s surface. It is shown that torque control is equivalent to weld power control and causes a uniform amount of energy per unit length to be deposited along the weld seam. It is concluded that the feedback signal of torque provides a better indicator of tool depth into the workpiece than axial force. Torque is more sensitive to tool depth than axial force. Thus, it is concluded that torque control is better suited for keeping a friction stir welding tool properly engaged with the workpiece for application to robotics, automation, and manufacturing.

Similar content being viewed by others

References

Thomas W et al (1995) Friction stir butt welding, U.S. Patent 5,460,317, October 24

Schneider J (2007) Temperature distribution and resulting metal flow, friction stir welding and processing, ASM International, Chapter 3, pp 37–50

Smith C (2000) Robotic friction stir welding using a standard industrial robot. 2nd Friction Stir Welding International Symposium. Gothenburg, Sweden

Soron M, Kalaykov I (2006) A robot prototype for friction stir welding, robotics, automation and mechatronics, 2006 IEEE Conference, pp 1–5

Zhao X, Kalya P, Landers R, Krishnamurthy K (2007) Design and implementation of a nonlinear axial force controller for friction stir welding processes. proceedings of the 2007 American Control Conference, pp 5553–5558

Craig John (2005) Introduction to robotics mechanics and control, 3rd edn. Pearson Prentice Hall

Fleming P (2009) Monitoring and control in friction stir welding, PhD Dissertation, Vanderbilt University

Ogata (2002) Linear control theory, 4th edn. Pearson Prentice Hall

Nunes A, Bernstein E, McClure J (2000) A rotating plug model for fiction stir welding, Presented at 81st American Welding Society Annual Convention

Wikipedia, http://en.wikipedia.org/wiki/Friction_stir_welding, 2009

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Longhurst, W.R., Strauss, A.M., Cook, G.E. et al. Torque control of friction stir welding for manufacturing and automation. Int J Adv Manuf Technol 51, 905–913 (2010). https://doi.org/10.1007/s00170-010-2678-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2678-3