Abstract

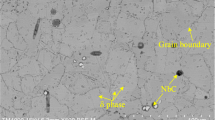

17-4PH stainless steel is a widely used martensitic precipitation hardening stainless steel, and it is a typical difficult-to-cut material. This paper presents an effort to investigate the insert damage process and its effects on the machined surface roughness during the whole process of high-speed face milling the 17-4PH stainless steel. It was found that although the endurance failure, adhesive wear, and diffusion wear altogether contributed to the insert damage, the insert was more inclined to be damaged by the fatigue breakage at the low cutting speed, and by flaking when the cutting speed increased. Notch wear was found during the cutting process for all the milling tests, and the higher cutting speed could severely accelerate its formation. During the cutting process, the average roughness value and its deviation on the machined surface significantly increased after the notch wear. The spindle vibration and big gap between the cutting edge and the workpiece caused by insert damage could lead to the severe chip winding, and further to the generation of scratches and bulges. In the actual production, it is recommended to periodically monitor the tool wear condition and machined surface roughness during the whole cutting tool life cycle, besides exploring appropriate cutting parameters.

Similar content being viewed by others

References

Tian X, Zhao J, Zhao J, Gong Z, Dong Y (2013) Effect of cutting speed on cutting forces and wear mechanisms in high-speed face milling of Inconel 718 with Sialon ceramic tools. Int J Adv Manuf Technol 69(9-12):2669–2678

Reddy NSK, Rao PV (2006) Selection of an optimal parametric combination for achieving a better surface finish in dry milling using genetic algorithms. Int J Adv Manuf Technol 28(5-6):463–473

Chien WT, Tsai CS (2003) The investigation on the prediction of tool wear and the determination of optimum cutting conditions in machining 17-4PH stainless steel. J Mater Process Technol 140(1-3):340–345

Klim Z, Ennajimi E, Balazinski M, Fortin C (1996) Cutting tool reliability analysis for variable feed milling of 17-4PH stainless steel. Wear 195:206–213

Junior AB, Diniz AE, Filho FT (2009) Tool wear and tool life in end milling of 15–5 PH stainless steel under different cooling and lubrication conditions. Int J Adv Manuf Technol 43(7-8):756–764

Cui X, Zhao J, Dong Y (2013) The effects of cutting parameters on tool life and wear mechanisms of CBN tool in high-speed face milling of hardened steel. Int J Adv Manuf Technol 66(5-8):955–964

Sai K, Bouzid W (2005) Roughness modeling in up-face milling. Int J Adv Manuf Technol 26(4):324–329

Sai WB, Salah NB, Lebrun JL (2001) Influence of machining by finishing milling on surface characteristics. Int J Mach Tools Manuf 41(3):443–450

Ding T, Zhang S, Wang Y, Zhu X (2010) Empirical models and optimal cutting parameters for cutting forces and surface roughness in hard milling of AISI H13 steel. Int J Adv Manuf Technol 51(1-4):45–55

Zhang C, Guo S, Zhang H, Zhou L (2013) Modeling and predicting for surface topography considering tool wear in milling process. Int J Adv Manuf Technol 68(9-12):2849–2860

Zeng W, Jiang X, Blunt L (2009) Surface characterisation-based tool wear monitoring in peripheral milling. Int J Adv Manuf Technol 40(3-4):226–233

Penalva ML, Arizmendi M, Diaz F, Fernandez J, Katz Z (2002) Effect of tool wear on roughness in hard turning. CIRP Ann Manuf Technol 51(1):57–60

Pavel R, Marinescu I, Deis M, Pillar J (2005) Effect of tool wear on surface finish for a case of continuous and interrupted hard turning. J Mater Process Technol 170(1):341–349

Coker SA, Shin YC (1996) In-process control of surface roughness due to tool wear using a new ultrasonic system. Int J Mach Tools Manuf 36(3):411–422

Zou B, Zhou H, Huang C, Xu K, Wang J (2015) Tool damage and machined-surface quality using hot-pressed sintering Ti (C7N3)/WC/TaC cermet cutting inserts for high-speed turning stainless steels. Int J Adv Manuf Technol 79(1-4):197–210

Sun Y, Sun J, Li J, Xiong Q (2014) An experimental investigation of the influence of cutting parameters on cutting temperature in milling Ti6Al4V by applying semi-artificial thermocouple. Int J Adv Manuf Technol 70(5-8):765–773

Smith S, Melkote SN, Lara-Curzio E, Watkins TR, Allard L, Riester L (2007) Effect of surface integrity of hard turned AISI 52100 steel on fatigue performance. Mater Sci Eng A 459(1):337–346

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, G., Zou, B., Huang, C. et al. Tool damage and its effect on the machined surface roughness in high-speed face milling the 17-4PH stainless steel. Int J Adv Manuf Technol 83, 257–264 (2016). https://doi.org/10.1007/s00170-015-7564-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7564-6