Abstract

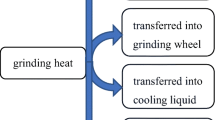

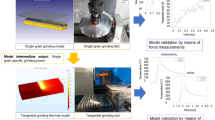

Grind-hardening is a manufacturing process that uses the heat generated within the grinding zone in order to produce surface hardening. After the process, workpieces present dimensional inaccuracies and a poor surface finish. Thus, a finishing grinding operation has to be carried out. For a successful implementation of the whole process, two problems have to be solved. Firstly, the desired hardened depth has to be achieved in the hardening stage. Secondly, surface softening has to be controlled during the finishing stage. The objective of this work is to address the modelling of the whole process so that the experimental effort during its set up is reduced. To do this, firstly, a thermal model is developed for the estimation of the hardened depth. This model considers the heat evacuated by the chips in a simplified way and takes into account the heat consumed by the fast austenitization process through an original methodology. Secondly, a model is proposed for the estimation of surface softening during finishing grinding. A methodology is presented for the prediction of surface hardness under non-isothermal tempering. Both models are calibrated and validated for the AISI 1045 steel, and the predicted results are in agreement with the experimental data for the studied grinding regimes. In this regard, the grind-hardening model predicts the hardness penetration depth (HPD) precisely for HPD values over 0.2 mm. The finishing model estimates the surface hardness after the finishing of the workpiece with an error lower than 6 %.

Similar content being viewed by others

References

Liu M, Nguyen T, Zhang L, Wu Q, Sun D (2015) Effect of grinding-induced cyclic heating on the hardened layer generation in the plunge grinding of a cylindrical component. Int J Mach Tools Manuf 89:55–63

Brockhoff T (1999) Grind-hardening: a comprehensive view. Ann CIRP 48:255–260

Songyong L, Gang Y, Jiaqiang Z, Xiaohui L (2015) Numerical and experimental studies on grind-hardening cylindrical surface. Int J Adv Manuf Technol 76:487–499

Salonitis K, Chondros T, Chryssolouris G (2008) Grinding wheel effect in the grind-hardening process. Int J Adv Manuf Technol 38(1–2):48–58

Nguyen T, Zhang LC (2010) Realisation of grinding-hardening in workpieces of curved surfaces—part 1: plunge cylindrical grinding. Int JMach Tools Manuf 51(4):309–319

Kolkwitz B, Föckerer T, Heinzel C, Zäh MF, Brinksmeier E (2011) Experimental and numerical analysis of the surface integrity resulting from outer-diameter grind-hardening. Procedia Eng 19:222–227

Föckerer T, Kolkwitz B, Heinzel C, Zäh MF (2012) Experimental and numerical analysis of transient behaviour during grind-hardening of AISI 52100. Prod Eng 6(6):559–568

Malkin S, Guo C (2008) Grinding technology: theory and application of machining with abrasives. Industrial Press, New York

Jaeger JC (1942) Moving sources of heat and the temperature at sliding contacts. ProcRSoc New South Wales 76:203–224

Maksoud TMA (2005) Heat transfer model for creep-feed grinding. J Mater Process Technol 168:448–463

Jin T, Cai GQ (2001) Analytical thermal models of oblique moving heat source for deep grinding and cutting. J Manuf Sci Eng 123(2):185–190

Doman D, Warkentin A, Bauer R (2009) Finite element modelling approaches in grinding. Int J Mach Tools Manuf 49(2):109–116

M.Schneider (1999) Auswirkungen thermomechanischer Vorgänge beim Werkzeug-schleifen, University of Dortmund, (PhD Thesis)

Lefebvre A, Lanzetta F, Lipinski P, Torrance AA (2012) Measurement of grinding temperatures using a foil/thermocouple. Int J Mach Tools Manuf 58:1–10

Malkin S, Guo C (2007) Thermal analysis of grinding. Ann CIRP 56(2):760–782

Föckerer T, Zäh MF, Zhang OB (2013) A three-dimensional analytical model to predict the thermo-metallurgical effects within the surface layer during grinding and grind-hardening. Int J Heat Mass Transf 56:223–237

Zäh MF, Brinksmeier E, Heinzel C, Huntemann J-W, Föckerer T (2009) Experimental and numerical identification of process parameters of grind-hardening and resulting part distortions. Prod Eng 3(3):271–279

Salonitis K, Chryssolouris G (2007) Cooling in grind-hardening operations. Int J Adv Manuf Technol 33(3-4):285–297

Vincent Y, Jullien J, Gilles P (2005) Thermo-mechanical consequences of phase transformations in the heat-affected zone using a cyclic uniaxial test. Int J Solids and Struct 42(14):4077–4098

Zhang Y, Ge P, Be W (2015) Plane grind-hardening distortion analysis and the effect to grind-hardening layer. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6612-y

FP Incropera, DP Dewitt (1990) Fundamentals of heat and mass transfer, third ed. John Wiley & Sons Inc

Hollomon J, Jaffe L (1945) Time–temperature relations in tempering steel. Trans AIME 162:223–249

Rowe WB, Morgan MN, Qi HS, Zheng HW (1993) The effect of deformation on the contact area in grinding. Ann CIRP 42:409–412

M. Noyen (2008) Analyse der mechanischen Belastungsverteilung in der Kontaktzone beim Längs-Umfangs-Planschleifen, University of Dortmund, (PhD Thesis)

Brinksmeier E, Brockhoff T (1997) Advanced grinding processes for surface strengthening of structural parts. Mach Sci Technol 1(2):299–309

(1973) Atlas zur Wärmebehandlung der Stähle (3), Zeit-Temperatur-Austenitisierung-Schaubilder, Verlag Stahleisen, Düsseldorf

Leblond JB, Devaux J (1984) A new kinetic model for aniso-thermal metallurgical transformation in steels including effect of austenite grain size. Acta Metall 32(1):137–146

Jin T, Rowe W, McCormack D (2002) Temperatures in deep grinding of finite workpieces. Int J Mach Tools Manuf 42:53–59

Alonso U, Ortega N, Sanchez JA, Pombo I, Izquierdo B, Plaza S (2015) Hardness control of grind-hardening and finishing grinding by means of area-based specific energy. Int J Mach Tools Manuf 88:24–33

García E, Méresse D, Pombo I, Harmand S, Sánchez JA (2014) Identification of heat partition in grinding related to process parameters, using the inverse heat flux conduction model. Appl Therm Eng 66(1–2):122–130

Reti T, Felde I, Grum J, Colas R, Sanchez G, Moita de Deus A (2010) Extension of isothermal time-temperature parameters to non-isothermal conditions: application to the simulation of rapid tempering. Strojniški Vestn J Mech Eng 56(56):84–92

Grange RA, Braughman, RW (1956) Hardness of tempered martensite in carbon and low alloy steels. In: Transactions of American Society for Metals v. XLVII, 165-197

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ortega, N., Alonso, U., Sánchez, J.A. et al. Modelling of the hardening and finishing stages of grind-hardened workpieces. Int J Adv Manuf Technol 82, 435–449 (2016). https://doi.org/10.1007/s00170-015-7378-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7378-6