Abstract

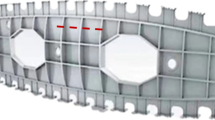

The forming quality in the transitional region largely determines the formability of local loading forming of the large-scale rib-web component. Thus, it is very critical to determine the forming limit considering defects in the transitional region during local loading forming. In this paper, the stepwise searching method based on Kriging metamodels of defect indexes is adopted to determine the above forming limit. First, the finite element (FE) simulation of the transitional region during local loading forming and the evaluation indexes for folding and cavum defects are introduced. Then, the Kriging metamodels of defect indexes are developed based on quantities of FE simulation results under various geometry parameters. During Kriging metamodeling, in order to guarantee the accuracy of the metamodel in the global design space and interesting region simultaneously, the space-filling maximin Latin hypercube designs (maximin LHDs) and sequential sampling approach are employed to design sample points. After metamodeling, extra random samples designed within the whole space are simulated to validate the developed Kriging metamodels. At last, the method of determining the forming limit considering defects in the transitional region is presented and applied to two specific transitional region models. It is realized through stepwise searching based on Kriging metamodels of defect indexes. The application results show that the proposed method is an effective and reliable method to determine the forming limit considering defects in the transitional region. It would provide an important guideline in the processing design of local loading forming of titanium alloy large-scale rib-web components.

Similar content being viewed by others

References

Shen G, Furrer D (2000) Manufacturing of aerospace forgings. J Mater Process Technol 98:189–195

Zhang DW, Yang H, Sun ZC, Fan XG (2012) Deformation behavior of variable-thickness region of billet in rib-web component isothermal local loading process. Int J Adv Manuf Technol 63(1–4):1–12

Zhang DW, Yang H (2013) Metal flow characteristics of local loading forming process for rib-web component with unequal-thickness billet. Int J Adv Manuf Technol 68(9–12):1949–1965

Zhang DW, Yang H, Sun ZC (2010) Analysis of local loading forming for titanium-alloy T-shaped components using slab method. J Mater Process Technol 210:258–266

Zhang DW, Yang H (2013) Preform design for large-scale bulkhead of TA15 titanium alloy based on local loading features. Int J Adv Manuf Technol 67:2551–2562

Sun ZC, Yang H (2009) Microstructure and mechanical properties of TA15 titanium alloy under defects-step local loading forming. Mater Sci Eng A 523(1–2):184–192

Fan XG, Yang H, Sun ZC, Zhang DW (2010) Effect of deformation inhomogeneity on the microstructure and mechanical properties of large-scale rib-web component of titanium alloy under local loading forming. Mater Sci Eng A 527:5391–5399

Gao PF, Yang H, Fan XG (2014) Quantitative analysis of the material flow in transitional region during isothermal local loading forming of Ti-alloy rib-web component. Int J Adv Manuf Technol 75(9–12):1339–1347

Zhang DW, Yang H (2013) Numerical study of the friction effects on the metal flow under local loading way. Int J Adv Manuf Technol 68:1339–1350

Zhang DW, Yang H, Sun ZC, Fan XG (2011) Deformation behavior under die partitioning boundary during titanium alloy large-scale rib-web component forming by isothermal local loading. Proceedings of the 12th World Conference on Titanium. Science Press, Beijing, p 328

Zhang DW, Yang H (2014) Distribution of metal flowing into unloaded area in the local loading process of titanium alloy rib-web component. Rare Metal Mater Eng 43(2):296–300

Gao PF, Yang H, Fan XG, Lei PH (2014) Forming defects control in transitional region during isothermal local loading of Ti-alloy rib-web component. Int J Adv Manuf Technol 76(5–8):857–868

Chen FK, Huang TB, Wang SJ (2007) A study of flow-through phenomenon in the press forging of magnesium-alloy sheets. J Mater Process Technol 187–188:770–774

Sun ZC, Yang H (2007) Study on forming limit and feasibility of tube axial compressive process. J Mater Process Technol 187–188:292–295

Wang GG, Shan S (2006) Review of metamodeling techniques in support of engineering design optimization. J Mech Des 129(4):370–380

Chen V, Tsui KL, Barton RR, Meckesheimer M (2006) A review on design, modeling and applications of computer experiments. IIE Trans 38(4):273–291

Guan Y, Bai X, Liu M, Song L, Zhao G (2015) Preform design in forging process of complex parts by using quasi-equipotential field and response surface methods. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6775-6

Kleijnen J (2009) Kriging metamodeling in simulation: a review. Eur J Oper Res 192:707–716

Beers W, Kleijnen J (2004) Kriging interpolation in simulation: a survey. Proceedings of the 2004 Winter Simulation Conference

Martin JD, Simpson TW (2003) A study on the use of Kriging models to approximate deterministic computer models. Proceedings of DETC’03 ASME 2003 Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, September 2–6

Martin JD, Simpson TW (2004) On the use of Kriging models to approximate deterministic computer models. Proceedings of DETC’04: ASME 2004 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Salt Lake City, September 28 - October 2

Gao PF, Yang H, Fan XG, Lei PH (2015) Quick prediction of the folding defect in transitional region during isothermal local loading forming of titanium alloy large-scale rib-web component based on folding index. J Mater Process Technol 219:101–111

Shen CW (2007) Research on material constitution models of TA15 and TC11 titanium alloys in hot deformation process. Master Thesis, Northwestern Polytechnical University

Guo HZ (2009) Forging of alloy steel and nonferrous alloy, 2nd edn. Northwestern Polytechnical University Press, Xi’an, pp 220–256 (in Chinese)

Simpson TW, Lin D, Chen W (2001) Sampling strategies for computer experiments: design and analysis. Int J Reliab Appl 2(3):209–240

Jin R, Chen W, Sudjianto A (2002) On sequential sampling for global metamodeling in engineering design. Proceedings of DETC’02: ASME 2002 Design Engineering Technical Conferences And Computers and Information in Engineering Conference. Montreal, September 29-October 2

Jin R, Chen W, Simpson TW (2001) Comparative studies of metamodeling techniques under multiple modeling criteria. Struct Multidiscip Optim 23(1):1–13

Simpson TW (1998) Comparison of response surface and Kriging models in the multidisciplinary design of an aerospike nozzle. Langley Research Center, NASA NASA/CR-1998-206935, Hampton, VA, February

Lophaven SN, Nielsen HB, Sondergaard J (2002) DACE: a Matlab Kriging toolbox, version 2.0. IMM Technical University of Denmark, Lyngby. ISBN DACE: a Matlab Kriging toolbox

Kleijnen J, Van BW, Van NI (2010) Constrained optimization in expensive simulation: novel approach. Eur J Oper Res 202(1):164–174

Rennen G, Husslage B, Dam ER, Hertog DD (2009) Nested maximin Latin hypercube designs. ISSN 0924–7815, No. 2009–06

Grosso A, Jamali A, Locatelli M (2009) Finding maximin Latin hypercube designs by Iterated Local Search heuristics. Eur J Oper Res 197(2):541–547

Shipley RJ (1988) Precision forging, forging process, ASM Handbook. ASM International, USA

Ge XW, Han XH, Chen W, Zhou XH (2010) Processing parameters optimization based on Kriging metamodel for gas-assisted injection molding. J Chem Ind Eng 61(4):909–915 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, P., Yang, H., Fan, X. et al. Forming limit of local loading forming of Ti-alloy large-scale rib-web components considering defects in the transitional region. Int J Adv Manuf Technol 80, 1015–1026 (2015). https://doi.org/10.1007/s00170-015-7061-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7061-y