Abstract

Friction plays an important role in bulk metal-forming process. Especially, it has an important influence on metal flow in the local loading process. In the present study, the influence of friction on the metal flow in local loading forming process of rib-web component was analyzed by using analytical method, numerical simulation, and experiment. Constant shear friction model was employed in the analytical analysis and numerical simulation. Two kinds of local loading experiment were carried out, which differ in the shape of billet. The results in the present study indicated that (a) in local loading state, increasing friction is beneficial to reduce or avoid the occurrence of shearing deformation behavior; (b) the metal flowing into rib cavity would increase if friction factor increases; (c) as the width of local loading increases or thickness difference of variable-thickness region decreases, the friction effect will reduce.

Similar content being viewed by others

References

Yang H, Fan XG, Sun ZC, Guo LG, Zhan M (2011) Recent developments in plastic forming technology of titanium alloys. Sci China Tech Sci 54:490–501

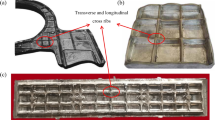

Shan D, Xu W, Si C, Lu Y (2007) Research on local loading method for an aluminium-alloy hatch with cross ribs and thin webs. J Mater Process Technol 187–188:480–485

Sun ZC, Yang H (2008) Mechanism of unequal deformation during large-scale complex integral component isothermal local loading forming. Steel Res Int 79:601–608 (Special Edition 1)

Kalpakjiana S (1985) Recent progress in metal forming tribology. Ann CIRP 34(2):585–592

Petersen SB, Martins PAF, Bay N (1997) Friction in bulk metal forming: a general friction model vs. the law of constant friction. J Mater Process Technol 66:186–194

Tan X (2002) Comparisons of friction models in bulk metal forming. Tribol Int 35:385–393

Joun MS, Moon HG, Choi IS, Lee MC, Jun BY (2009) Effects of friction laws on metal forming processes. Tribol Int 42:311–319

Liu Y, Yang H, Zhan M, Fu Z (2002) A study of the influence of friction conditions on the forging process of a blade with a tenon. J Mater Process Technol 123:42–46

Hsing SH, Ho HL (2004) Investigation of the influence of various process parameters on the radial forging processes by the finite element method (FEM). Int J Adv Manuf Technol 23:627–635

Malayappan S, Narayanasamy R (2004) An experiment analysis of upset forging of aluminium cylindrical billets considering the dissimilar friction conditions at flat die surface. Int J Adv Manuf Technol 23:636–643

Menezes PL, Kishore KK, Kailas SV (2009) Influence of friction during forming process—a study using a numerical simulation technique. Int J Adv Manuf Technol 40:1067–1076

Li F, Yuan SJ, Liu G, He ZB (2008) Research of metal flow behavior during extrusion with active friction. J Mater Eng Perform 17(1):7–14

Kobayashi S, Oh SI, Altan T (1989) Metal forming and the finite-element method. Oxford University Press, New York

Ghassemali E, Jarfors AEW, Tan MJ, Lim SCV (2013) On the microstructure of micro-pins manufactured by a novel progressive microforming process. Int J Mater Form 6(1):65–74

Ghassemali E, Tan MJ, Jarfors AEW, Lim SCV (2012) Progressive microforming process: towards the mass production of micro-parts using sheet metal. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4352-4

Zhang DW, Yang H, Sun ZC (2010) Analysis of local loading forming for titanium-alloy T-shaped components using slab method. J Mater Process Technol 210:258–266

Zhang LL, Dai YR, Cao F, Zeng Q (2003) Optimization of material flow in forging by using local friction. Forg Stamp Technol 28(3):40–43 (in Chinese)

Fan XG, Yang H, Sun ZC, Zhang DW (2010) Effect of deformation inhomogeneity on the microstructure and mechanical properties of large-scale rib-web component of titanium alloy under local loading forming. Mater Sci Eng, A 527(21–22):5391–5399

Sun ZC, Yang H (2009) Forming quality of titanium alloy large-scale integral components isothermal local loading. Arab J Sci Eng 34(1C):35–45

Zhang DW, Yang H, Li HW, Fan XG (2012) Friction factor evaluation by FEM and experiment for TA15 titanium alloy in isothermal forming process. Int J Adv Manuf Technol 60:527–536

Li LX, Peng DS, Liu JA, Liu ZQ, Jiang Y (2000) An experiment study of the lubrication behavior of A5 glass lubricant by means of the ring compression tests. J Mater Process Technol 102:138–142

Zhang DW, Yang H, Sun ZC, Fan XG (2010) A new FE modeling method for isothermal local loading process of large-scale complex titanium alloy components based on DEFORM-3D. In: Barlat F, Moon YH, Lee MG (Eds.) AIP Conference Proceedings 1252, American Institute of Physics, Melville, New York, pp. 439–446

Zhang DW, Yang H (2013) Metal flow characteristics of local loading forming process for rib-web component with unequal-thickness billet. Int J Adv Manuf Technol. doi:10.1007/s00170-013-4800-9

Shen CW (2007) Research on material constitution models of TA15 and TC11 titanium alloys in hot deformation processes. Master Thesis, Northwestern Polytechnical University (in Chinese)

Dutta A, Rao AV (1997) Simulation of isothermal forging of compressor disc by combined numerical and physical modeling techniques. J Mater Process Technol 72:392–395

Zhang DW (2012) Forming regulation and preform design of large-scale complex titanium alloy component in isothermal local loading process. PhD Dissertation, Northwestern Polytechnical University (in Chinese)

Zhang DW, Yang H, Sun ZC, Fan XG (2011) Influences of fillet radius and draft angle on the local loading process of titanium alloy T-shaped components. Trans Nonferrous Met Soc China 21(12):2693–2074

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, DW., Yang, H. Numerical study of the friction effects on the metal flow under local loading way. Int J Adv Manuf Technol 68, 1339–1350 (2013). https://doi.org/10.1007/s00170-013-4925-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-4925-x