Abstract

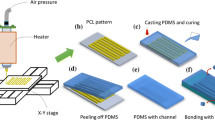

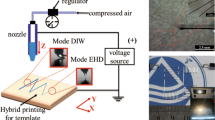

This study aims to investigate two peel demolding schemes through numerical simulations and experimental studies in order to improve the yield rate of the automated system for demolding of the polydimethylsiloxane (PDMS) micropillars with aspect ratio of 6. Numerical models based on the explicit dynamic finite element analysis by using LS-DYNA are developed to identify an optimal demolding scheme which can minimize the maximum stress of microstructures during demolding. A scale-up modeling approach is proposed to increase the numerical time-step for microscale problems in order to reduce the computational time. The experimental tests are also carried out which agree with the findings from numerical simulations. From this study, the roller-based demolding system is identified as the optimal approach in our analysis cases which can minimize the distortion and collapse of micropillars. The yield rate of the roller-based demolding system in our experimental study can be up to 99 %.

Similar content being viewed by others

References

Sollier E, Murray C, Maoddi P, Di Carlo D (2011) Rapid prototyping polymers for microfluidic devices and high pressure injections. Lab Chip 11:3752–3765

Jáuregui AL, Siller HR, Rodríguez CA, Elías-Zúñiga A (2010) Evaluation of micromechanical manufacturing processes for microfluidic devices. Int J Adv Manuf Technol 48:963–972

Chen P-C, Pan C-W, Lee W-C, Li K-M (2014) An experimental study of micromilling parameters to manufacture microchannels on a PMMA substrate. Int J Adv Manuf Technol 71:1623–1630

Chen L, Wang G, Lim C, Seong GH, Choo J, Lee EK, Kang SH, Song JM (2009) Evaluation of passive mixing behaviors in a pillar obstruction poly(dimethylsiloxane) microfluidic mixer using fluorescence microscopy. Microfluid Nanofluid 7:267–273

Lee D, Mekaru H, Hiroshima H, Matsumoto S, Itoh T, Takahashi M, Maeda R (2010) 3D UV-microreplication using cylindrical PDMS mold. Microsyst Technol 16:1399–1411

Yeh PY, Rossi N, Kizhakkedathu J, Chiao M (2010) A silicone-based microfluidic chip grafted with carboxyl functionalized hyperbranched polyglycerols for selective protein capture. Microfluid Nanofluid 9:199–209

Shao G, Wu J, Cai Z, Wang W (2012) Fabrication of elastomeric high-aspect-ratio microstructures using polydimethylsiloxane (PDMS) double casting technique. Sensors Actuators A Phys 178:230–236

Fujii T (2002) PDMS-based microfluidic devices for biomedical applications. Microelectron Eng 61–62:907–914

Zhang K, Zhao LB, Guo SS, Shi BX, Lam TL, Leung YC, Chen Y, Zhao XZ, Chan HLW, Wang Y (2010) A microfluidic system with surface modified piezoelectric sensor for trapping and detection of cancer cells. Biosens Bioelectron 26:935–939

Huang CJ, Chen YH, Wang CH, Chou TC, Lee GB (2007) Integrated microfluidic systems for automatic glucose sensing and insulin injection. Sensors Actuators B Chem 122:461–468

Gunda N, Joseph J, Tamayol A, Akbari M, Mitra S (2013) Measurement of pressure drop and flow resistance in microchannels with integrated micropillars. Microfluid Nanofluid 14:711–721

Merino S, Schift H, Retolaza A, Haatainen T (2007) The use of automatic demolding in nanoimprint lithography processes. Microelectron Eng 84:958–962

Trabadelo V, Schift H, Merino S, Bellini S, Gobrecht J (2008) Measurement of demolding forces in full wafer thermal nanoimprint. Microelectron Eng 85:907–909

Yeo LP, Lam YC, Chan-Park MB, Joshi SC, Hardt DE (2005) Demolding of high aspect ratio polymeric micro-patterning. Int J Nanosci 4:543–549

Yeo LP, Joshi SC, Lam YC, Chan-Park MB, Hardt DE (2009) Numerical analyses of peel demolding for UV embossing of high aspect ratio micro-patterning. Microsyst Technol 15:581–593

Liu C-H, Lee K-M (2012) Dynamic modeling of damping effects in highly damped compliant fingers for applications involving contacts, ASME J. of Dynamic Systems, Measurement, and Control 134, 011005-1-9

Lee K-M, Liu C-H (2012) Explicit dynamic finite element analysis of an automated grasping process using highly damped compliant fingers. Comput Mathematics Appl 64:965–977

Cook RD, Malkus DS, Plesha ME, Witt RJ (2001) Concepts and Applications of Finite Element Analysis, 4th Edition, Wiley

Hallquist J (2006) LS-DYNA Theorey Manual, Livermore Software Technology Corporation

Mark JE (1999) Polymer data handbook. Oxford University Press, New York

Ou KS, Yan HY, Chen KS (2008) Mechanical characterization of KMPR by nano-indentation for MEMS applications. Strain 44:267–271

Penskiy I, Gerratt AP, Bergbreiter S (2011) Friction, adhesion and wear properties of PDMS films on silicon sidewalls. J Micromech Microeng 21:105013

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, CH., Chen, W., Su, W. et al. Numerical and experimental analysis of the automated demolding process for PDMS microfluidic devices with high-aspect ratio micropillars. Int J Adv Manuf Technol 80, 401–409 (2015). https://doi.org/10.1007/s00170-015-6959-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6959-8