Abstract

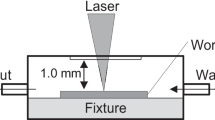

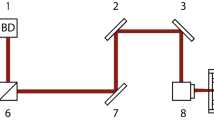

Underwater laser ablation is typically used to scribe a silicon wafer with low thermal damage and less redeposition of cut debris on the workpiece surface. However, the hydrodynamic characteristics of water and some particles suspending in water are able to disturb the laser beam during the ablation. As such, the overall laser cutting performance in water and cut results can become poor or even unacceptable in some ablating conditions. This study thus aims at enhancing the underwater laser ablation process by controlling the water flow rate and flow direction in a closed water chamber setup. A single-crystalline silicon wafer selected as a work sample in this study was grooved by a nanosecond pulse laser under different water flow rates in order to carry the excessive heat and cut debris away from the workpiece. According to the experimental findings, a deeper groove and less redeposition can be obtained when the ablation was performed in a higher water flow rate. By processing silicon in the flowing water, the significant disturbances of air bubbles, water waves, and cut debris to the laser beam can be minimized, hence gaining a better ablating performance than the laser ablation in still water. Furthermore, the plastic deformation of silicon was evident as per the presence of slip bands on the cut surface, where the band size was found to decrease with the increased water flow rate.

Similar content being viewed by others

References

Brousseau EB, Dimov SS, Pham DT (2010) Some recent advances in multi-material micro- and nano-manufacturing. Int J Adv Manuf Technol 47(1–4):161–180. doi:10.1007/s00170-009-2214-5

Hsiao WT, Tseng SF, Huang KC, Wang YH, Chen MF (2011) Pulsed Nd:YAG laser treatment of monocrystalline silicon substrate. Int J Adv Manuf Technol 56(1–4):223–231. doi:10.1007/s00170-011-3170-4

Sundaram SK, Mazur E (2002) Inducing and probing non-thermal transitions in semiconductors using femtosecond laser pulses. Nat Mater 1(4):217–224

Zhao X, Shin YC (2014) Ablation enhancement of silicon by ultrashort double-pulse laser ablation. Appl Phys Lett 105 (11):-. doi:doi:http://dx.doi.org/10.1063/1.4896350

Wan DP, Wang J, Mathew P (2011) Energy deposition and non-thermal ablation in femtosecond laser grooving of silicon. Mach Sci Technol 15(3):263–283. doi:10.1080/10910344.2011.595324

Tangwarodomnukun V, Wang J, Huang CZ, Zhu HT (2012) An investigation of hybrid laser–waterjet ablation of silicon substrates. Int J Mach Tools Manuf 56:39–49

Tangwarodomnukun V, Wang J (2009) Laser micromachining of silicon substrates. Adv Mater Res 76–78:416–421

Molian R, Neumann C, Shrotriya P, Molian P (2008) Novel laser/water-jet hybrid manufacturing process for cutting ceramics. J Manuf Sci E-T ASME 130(3):0310081–03100810

Richerzhagen B, Kutsuna M, Okada H, Ikeda T Waterjet-guided laser processing. In: Miyamoto I, Kobayashi KF, Sugioka K, Poprawe R, Helvajian H (eds) Proceedings of SPIE—The International Society for Optical Engineering, Osaka, 2002. Third Int Symp Laser Precis Microfabrication. pp 91–94

Kaakkunen JJJ, Silvennoinen M, Paivasaari K, Vahimaa P Water-assisted femtosecond laser pulse ablation of high aspect ratio holes. In: 6th International WLT Conference on Lasers in Manufacturing, LiM, Munich, 2011. pp 88–93. doi:10.1016/j.phpro.2011.03.110

Silvennoinen M, Kaakkunen JJJ, Paivasaari K, Vahimaa P (2013) Water spray assisted ultrashort laser pulse ablation. Appl Surf Sci 265:865–869. doi:10.1016/j.apsusc.2012.11.135

Mullick S, Madhukar YK, Roy S, Kumar S, Shukla DK, Nath AK (2013) Development and parametric study of a water-jet assisted underwater laser cutting process. Int J Mach Tools Manuf 68(0):48–55

Kruusing A (2004) Underwater and water-assisted laser processing: part 1—general features, steam cleaning and shock processing. Opt Lasers Eng 41(2):307–327

Tamura A, Sakka T, Fukami K, Ogata YH (2013) Dynamics of cavitation bubbles generated by multi-pulse laser irradiation of a solid target in water. Appl Phys A-Mater 112(1):209–213

Li M, Zhang H, Shen Z, Lu J, Ni X (2005) Physical analyses of optical breakdown and plasma formation in water induced by laser. Guangzi Xuebao 34(11):1610–1614

Chen X, Xu RQ, Chen JP, Shen ZH, Jian L, Ni XW (2004) Shock-wave propagation and cavitation bubble oscillation by Nd:YAG laser ablation of a metal in water. Appl Opt 43(16):3251–3257. doi:10.1364/ao.43.003251

Fabbro R, Fournier J, Ballard P, Devaux D, Virmont J (1990) Physical study of laser-produced plasma in confined geometry. J Appl Phys 68(2):775–784

Daminelli G, Kruger J, Kautek W (2004) Femtosecond laser interaction with silicon under water confinement. Thin Solid Films 467(1–2):334–341

Liu H, Chen F, Wang X, Yang Q, Bian H, Si J, Hou X (2010) Influence of liquid environments on femtosecond laser ablation of silicon. Thin Solid Films 518(18):5188–5194. doi:10.1016/j.tsf.2010.04.043

Choo KL, Ogawa Y, Kanbargi G, Otra V, Raff LM, Komanduri R (2004) Micromachining of silicon by short-pulse laser ablation in air and under water. Mater Sci Eng A 372(1–2):145–162. doi:10.1016/j.msea.2003.12.021

Yuhong L, Liangcai X, Tielin S (2011) The research on mechanical effect etching Si in pulsed laser micromaching under water. Appl Surf Sci 257(8):3677–3681. doi:10.1016/j.apsusc.2010.11.105

Wee LM, Ng EYK, Prathama AH, Zheng H (2011) Micro-machining of silicon wafer in air and under water. Opt Laser Technol 43(1):62–71

Ali N, Bashir S, Umm IK, Akram M, Mahmood K (2013) Effect of dry and wet ambient environment on the pulsed laser ablation of titanium. Appl Surf Sci 270:49–57

Bashir S, Rafique MS, Nathala CS, Husinsky W (2014) Surface and structural modifications of titanium induced by various pulse energies of a femtosecond laser in liquid and dry environment. Appl Phys A-Mater 114:243–251

Iwatani N, Doan HD, Fushinobu K (2014) Optimization of near-infrared laser drilling of silicon carbide under water. Int J Heat Mass Transf 71:515–520. doi:10.1016/j.ijheatmasstransfer.2013.12.046

Krstulovic N, Shannon S, Stefanuik R, Fanara C (2013) Underwater-laser drilling of aluminum. Int J Adv Manuf Technol:1–9

Muhammad N, Whitehead D, Boor A, Li L (2010) Comparison of dry and wet fibre laser profile cutting of thin 316L stainless steel tubes for medical device applications. J Mater Process Technol 210(15):2261–2267

Duangwas S, Tangwarodomnukun V, Dumkum C (2014) Development of an overflow-assisted underwater laser ablation. Mater Manuf Process 29(10):1226–1231. doi:10.1080/10426914.2014.930896

Tangwarodomnukun V, Wang J, Mathew P (2010) A comparison of dry and underwater laser micromachining of silicon substrates. Key Eng Mater 443:693–698

Optics and Optical Instruments Catalog (2012). Edmund optics, Singapore

Miller DC, Kempe MD, Kennedy CE, Kurtz SR (2011) Analysis of transmitted optical spectrum enabling accelerated testing of multijunction concentrating photovoltaic designs. Opt Eng 50(1):013003–013017. doi:10.1117/1.3530092

Yasutake K, Shimizu S, Umeno M, Kawabe H (1987) Velocity of twinning partial dislocations in silicon. J Appl Phys 61(3):940–946. doi:10.1063/1.338146

Ning XJ, Huvey N (1996) Observation of twins formed by gliding of successive surface-nucleated partial dislocations in silicon. Philos Mag Lett 74(4):241–245

Korte S, Barnard JS, Stearn RJ, Clegg WJ (2011) Deformation of silicon—insights from microcompression testing at 25–500 °C. Int J Plast 27(11):1853–1866. doi:10.1016/j.ijplas.2011.05.009

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Charee, W., Tangwarodomnukun, V. & Dumkum, C. Laser ablation of silicon in water under different flow rates. Int J Adv Manuf Technol 78, 19–29 (2015). https://doi.org/10.1007/s00170-014-6625-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6625-6