Abstract

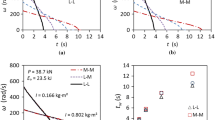

A two-dimensional axisymmetric model for the inertia friction welding (IFW) of a nickel-based superalloy was developed. The influences from the axial pressure, initial rotational speed, and moment of inertia of the flywheel on the interface temperature and axial shortening were systemically examined. The analysis shows that the mechanical energy mainly depends on the initial rotational speed, and a relatively high axial pressure will increase conversion efficiency from mechanical energy to effective welding heat. The axial shortening is found to be approximately proportional to the square of initial rotational speed while logarithmical to the axial pressure. Based on this work, the weldability criteria for IFW nickel-based superalloy was established. Additionally, the approach for welding parameter optimization was performed considering the evolution of temperature profiles from various parameters. The results show that the axial pressure has a more obvious effect on the width of high-temperature zone than the rotational speed during the quick shortening stage.

Similar content being viewed by others

References

Sathiya P, Aravindan S, Noorul A (2007) Effect of friction welding parameters on mechanical and metallurgical properties of ferritic stainless steel. Int J Adv Manuf Technol 31:1076–1082

Kalsi NS, Sharma VS (2011) A statistical analysis of rotary friction welding of steel with varying carbon in workpieces. Int J Adv Manuf Technol 57:957–967

Maalekian M (2007) Friction welding-critical assessment of literature. Sci Technol Weld J 12:738–759

Wang KK, Nagappan P (1970) Transient temperature distribution in inertia welding of steels. Weld J 49:419–426

Sluzalec A (1990) Transient temperature distribution in inertia welding of steels. Int J Mech Sci 32:467–78

Moal A, Massoni E (1995) Finite element simulation of the two similar parts. Eng Comput 12:497–512

Fu L, Duan LY, Du SG (2003) The coupled deformation and heat flow analysis by finite element method during friction welding. Weld J 82:65–70

Lee K, Samant A, Wu WT, Srivatsa S (2001) Finite element modeling of the inertia welding process. In: Mori KI (ed) Simulation of Materials Processing: Theory, Methods and Applications: Proc Conf NUMIFORM 2001, Toyohashi, Japan. pp 1095-1100

D’Alvise L, Massoni E, Walløe SJ (2002) Finite element modeling of the inertia friction welding process between dissimilar material. J Mat Process Tech Suppl 125–126:387–391

Wang L, Preuss M, Withers PJ, Baxter G, Wilson P (2005) Energy input based finite element process modeling of inertia welding. Metall Mater Trans B 36:513–523

Zhang QZ, Zhang LW, Liu WW, Zhang XG, Zhu WH, Qu S (2006) 3D rigid viscoplastic FE modeling of continuous drive friction welding process. Sci Technol Weld Joi 11:737–743

Maalekian M, Kozeschnik E, Brantner HP, Cerjak H (2008) Comparative analysis of heat generation in friction welding of steel bars. Acta Mater 56:2843–2855

Bennett CJ, Hyde TH, Shipway PH (2011) A transient finite element analysis of thermoelastic effects during inertia friction welding. Comput Mater Sci 50:2592–2598

Li WY, Wang FF (2011) Modeling of continuous drive friction welding of mild steel. Mater Sci Eng A 528:5921–5926

Xie XS, Dong JX, Fu SH, Zhang MC (2010) Research and development of γ″ and γ′ strengthened Ni–Fe base superalloy GH4169. Acta Metall Sin 40:1289–1302

Preuss M, Withers PJ, Baxter GJ (2006) A comparison of inertia friction welds in three nickel base superalloys. Mater Sci Eng A 437:38–45

Zhang LW, Pei JB, Zhang QZ, Liu CD, Zhu WH, Qu S, Wang JH (2007) The coupled fem analysis of the transient temperature field during inertia friction welding of GH4169. Acta Metall Sin (Engl Lett) 20:301–306

Lewandowski MS, Overfelt RA (1999) High temperature deformation behavior of solid and semi-solid alloy 718. Acta Mater 47:4695–4710

Demange JJ, Prakash V, Pereira JM (2009) Effects of material microstructure on blunt projectile penetration of a nickel-based super alloy. Int J Impact Eng 36:1027–1043

Grant B, Preuss M, Withers PJ, Baxter G, Rowlson M (2009) Finite element process modeling of inertia friction welding advanced nickel-based superalloy. Mat Sci Eng A 513–514:366–375

Ates H, Turker M, Kurt A (2007) Effect of friction pressure on the properties of friction welded MA956 iron-based superalloy. Mater Design 28:948–953

Yang LB, Gebelin JC, Reed RC (2011) Modelling of inertia welding of IN718 superalloy. Mater Sci Technol 27:1249–1264

Liu FC, Lin X, Zhao WW, Zhao XM, Chen J, Huang WD (2010) Effects of solution treatment temperature on microstructures and properties of laser solid forming GH4169 superalloy. Rare Metal Mater Eng 39:1519–1524

Bennett CJ, Hyde TH, Williams EJ (2007) Modeling and simulation of the inertia friction welding of shafts. P I Mech Eng L-J Mat 221:275–284

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, F.F., Li, W.Y., Li, J.L. et al. Process parameter analysis of inertia friction welding nickel-based superalloy. Int J Adv Manuf Technol 71, 1909–1918 (2014). https://doi.org/10.1007/s00170-013-5569-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5569-6