Abstract

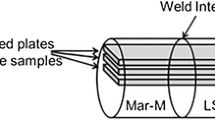

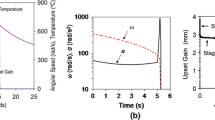

The inertia friction welding behavior of similar (LSHR to LSHR or Mar-M247 to Mar-M247) and dissimilar (LSHR to Mar-M247) alloy pairs was determined. The relationships between the IFW process parameters and welding response, such as the kinetics and efficiency of the transformation of the mechanical energy of the flywheel into heat of joining samples, weld duration, kinetics of flash formation, and bond quality were identified. Conditions resulting in sound welding were determined. It was found that the mechanistic behavior of each of the alloys during dissimilar welding can be approximated by the behavior of the respective alloy during similar welding. By contrast, the microstructure, microhardness and the thickness of the heat affected zone depended on the type of the alloy pair used during IFW.

Similar content being viewed by others

Abbreviations

- IFW:

-

Inertia friction welding

- I :

-

Flywheel moment of inertia

- E o :

-

Initial flywheel kinetic energy

- E :

-

Instant flywheel kinetic energy

- ω o :

-

Initial flywheel angular velocity

- ω :

-

Instant flywheel angular velocity

- P :

-

Axial compression force

- r :

-

Radius of cylindrical samples

- A = πr 2 :

-

Joining surface area

- σ = P/A :

-

Applied compression stress

- t :

-

Time

- t w :

-

Total welding time

- M :

-

Total torque

- M S :

-

Sample torque, i.e. torque caused by friction forces at the weld interface

- M B :

-

Machine torque

- \( E_{\text{S}} = \mathop \smallint \limits_{0}^{{t_{\text{w}} }} M_{\text{S}} \omega {\text{d}}t \) :

-

Sample energy (energy consumed at the weld interface)

- η = E S/E o :

-

Cumulative efficiency of the IFW process

- η inst = M S/M :

-

Instantaneous IFW process efficiency

- τ = 1.5M/(Ar):

-

Friction-induced shear stress

- L-L.X:

-

A LSHR to LSHR weldment (L-L) from a welding trial X, where X = 1, 2, 3, or 4

- M-M.X:

-

A Mar-M247 to Mar-M247 weldment (M-M) from a welding trial X, where X = 1, 2, 3, or 4

- L-M.X:

-

A LSHR to Mar-M247 weldment (L-M) from a welding trial X, where X = 1, 2, 3, or 4

- Δl :

-

Sample length loss during IFW

- Δl w :

-

Total sample length loss during IFW

- L :

-

The distance from the weld interface

- T :

-

Temperature

- T 0 :

-

Temperature at the weld interface

- T max0 :

-

Maximum temperature at the weld interface

- T 1mm :

-

Temperature on a cylindrical surface of a joining sample at L = 1 mm

- T max1mm :

-

Maximum registered temperature on a cylindrical surface of a joining sample at L = 1 mm

- Hv:

-

Vickers microhardness

- HAZ:

-

Heat affected zone

- ΔHAZ :

-

Thickness of heat affected zone

- YS:

-

Tensile yield stress

- UTS:

-

Ultimate tensile strength

- El:

-

Total tensile elongation to fracture

- E :

-

Young’s modulus

- SE:

-

Secondary electrons

- BSE:

-

Backscatter electrons

REFERENCES

F.J. Wallace, D.E. Spindler, and J.P. Thome: in Metals Handbook: Vol. 6: Welding, Brazing and Soldering, American Society for Metals, 1989.

M.M. Attallah, and M. Preuss: in Welding and Joining of Aerospace Materials, M.C. Chaturvedi, ed., Woodhead Publishing: Oxford, 2012.

A. Chamanfar, M. Jahazi and J. Cormier: Metall. Mater. Trans. A 2015, vol. 46, pp. 1639-1669.

O.N. Senkov, D.W. Mahaffey, S.L. Semiatin and C. Woodward: Metall. Mater. Trans A 2014, vol. 45, pp. 5545-5561.

O. N. Senkov, D. W. Mahaffey, S. L. Semiatin and C. Woodward: J. Mater. Eng. Perform. 2015, vol. 24, pp. 1173-1184.

Jian Luo, Longfei Li, Yaling Dong and Xiaoling Xu: International Journal of Advanced Manufacturing Technology 2014, vol. 70, pp. 1673-1681.

O.N. Senkov, D. W. Mahaffey and S. L. Semiatin: Metall. Mater. Trans. A 2016, vol. 47A, pp. 6121-6137.

D. W. Mahaffey, O. N. Senkov, R. Shivpuri and S. L. Semiatin: Metall. Mater. Trans. A 2016, vol. 47, pp. 3981-4000.

Z.W. Huang, H.Y. Li, M. Preuss, M. Karadge, P. Bowen, S. Bray, and G. Baxter: Metall. Mater. Trans. A, vol. 38A, pp. 1608–20, 2007.

M. Preuss, P. J. Withers and G. J. Baxter: Mater. Sci. Eng. A 2006, vol. 437, pp. 38-45.

F. Daus, H. Y. Li, G. Baxter, S. Bray and P. Bowen: Materials Science and Technology 2007, vol. 23, pp. 1424-1432.

Z. W. Huang, H. Y. Li, G. Baxter, S. Bray and P. Bowen: Journal of Materials Processing Technology 2011, vol. 211, pp. 1927-1936.

Z. W. Huang, H. Y. Li, G. Baxter, S. Bray and P. Bowen: Advanced Materials Research 2011, vol. 278, pp. 440-5.

O.N. Senkov, D.W. Mahaffey, D.J. Tung, W. Zhang and S.L. Semiatin: Metall. Mater. Trans A 2017, vol. 48, pp. 3328-3342.

O.N. Senkov, D.W. Mahaffey and S.L. Semiatin: J. Mater. Process. Technol. 2017, vol. 250, pp. 156-168.

S.L. Semiatin, K.E. MacClary, A.D. Rollett, C.G. Roberts, E.J. Payton, F. Zhang and T.P. Cabb: Metall. Mater. Trans. A 2013, vol. 44, pp. 2778-2798.

M. Kaufman: in Fifth International Symposium on Superalloys, TMS, Warrendale, PA, 1984, pp 43–52.

S.L. Semiatin, D.W. Mahaffey, D.J. Tung, W. Zhang and O.N. Senkov: Metall. Mater. Trans A 2017, vol. 48A, pp. 1864-1879.

ACKNOWLEDGMENTS

Inertia-friction-welding experiments were conducted at EWI, Inc., Columbus, Ohio with the technical assistance of David Workman (EWI) and Mark Ruddell (UDRI). Valuable discussions with Andrew Rosenberger (AFRL), William Musinski (AFRL), Daniel Tung (OSU), Rajiv Shivpuri (OSU), and Wei Zhang (OSU) are much appreciated. O.N. Senkov acknowledges financial support through the Air Force on-site Contract FA8650-15-D-5230 managed by UES, Inc., Dayton, OH.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 3, 2018.

Rights and permissions

About this article

Cite this article

Senkov, O.N., Mahaffey, D.W. & Semiatin, S.L. A Comparison of the Inertia Friction Welding Behavior of Similar and Dissimilar Ni-Based Superalloys. Metall Mater Trans A 49, 5428–5444 (2018). https://doi.org/10.1007/s11661-018-4853-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4853-3