Abstract

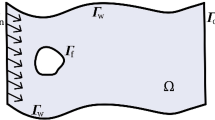

For most three-dimensional analytical solutions proposed for the extrusion of shaped sections, the axial component of the velocity vector has been assumed to be constant at each cross section throughout the deforming zone. This shortcoming means that these velocity fields are not in accordance with the reality of the extrusion problem, and hence, the upper bounds based on such fields give high values for the extrusion pressure. To overcome this, a new formulation has been presented in this paper for which a kinematically admissible velocity field has been developed using a variable axial velocity component. For this purpose, curved surfaces of velocity discontinuities at the entry and exit have been proposed and incorporated into the formulation for the extrusion of shaped sections from circular billets. As an example, a square profiled section has been chosen for the extrusion problem. The upper bound on extrusion pressure was computed using the new formulation. It was shown that the initial velocity discontinuity surface at the entry to the deforming region was flat, and as one travels into the deforming region towards the exit section, the velocity discontinuity surface gradually became convex, having the highest convexity at the exit section. This was contrary to what has been suggested in the literature so far. The measure of convexity depends on the extrusion parameters which have been investigated in this work. Experiments were also carried out to verify the theoretical results, and good agreements were observed between the two. Comparison of the present results with similar previous works showed good improvements as well.

Similar content being viewed by others

References

Gunasekera JS, Hoshino S (1980) Extrusion of non-circular sections through shaped dies. In: Proceedings of Annals of the CIRP 141–145

Han CH, Yang DY, Kiuchi M (1986) New formulation for three dimensional extrusions and its application to extrusion of clover sections. Int J Mech Sci 28:201–218

Chitkara NR, Abrinia K (1990) A generalized upper-bound solution for three-dimensional extrusion of shaped sections using CAD/CAM bilinear surface dies. In: Proceedings 28th. Int Matador Conf 18–19 April

Lee CM, Yang DY, Kim MU (1990) Numerical analysis of three-dimensional extrusion of arbitrarily shaped sections by the method of weighted residuals. Int J Mech Sci 32:65–82

Celik KF, Chitkara NR (2000) Application of an upper bound method to off-centric extrusion of square sections, analysis and experiments. Int J Mech Sci 42:321–345

Wu CW, Hsu RQ (2000) A universal velocity field for the extrusion of non-axisymmetric rods with non-uniform velocity distribution in the extrusion direction. J Mat Proc Tech 97:180–185

Abrinia K, Bloorbar H (2000) A new improved upper bound solution for the extrusion of shaped sections using CAD techniques. In: Proceedings of COMPLAS VI Conference, Barcelona, Spain

Ajiboye JS, Adeyemi MB (2007) Upper bound analysis for extrusion at various die land lengths and shaped profiles. Int J Mech Sci 49:335–351

Malpani M, Kumar S (2007) A feature based analysis of tube extrusion. J Mat Proc Tech 190:363–374

Abrinia K, Makaremi M (2008) A new three dimensional solution for the extrusions of sections with larger dimensions than the initial billet. J Mat Proc Tech 205:259–271

Assempour A, Hassannejadasl A (2009) Minimization of the exit profile curvature in non-symmetric T-shaped sections in the extrusion process. Mater Des 30:1350–1355

Sahoo RK, Samantaray PR, Sahoo SK, Sahoo B, Kar PK (2009) Round-to-channel section extrusion through linearly converging die: a three-dimensional analysis. Int J Adv Manuf Technol 41(7-8):677–683

Sahoo SK, Sahoo B, Patra LN, Paltasingh UC, Samantaray PR (2010) Three-dimensional analysis of round-to-angle section extrusion through straight converging die. Int J Adv Manuf Technol 49(5-8):505–512

Avitzur B (1968) Metal forming: processes and analysis. Original edition, McGraw-Hill Book Co., Reprint with revisions and corrections, 1979. Robert Krieger, New York

Gunasekera JS, Hoshino S (1985) Analysis of extrusion of polygonal sections through streamlined dies. J Eng Ind 107:229–233

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abrinia, K., Farahmand, P. & Parchami-Sarghin, M. Formulation of a new generalized kinematically admissible velocity field with a variable axial component for the forward extrusion of shaped sections. Int J Adv Manuf Technol 70, 1427–1435 (2014). https://doi.org/10.1007/s00170-013-5365-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5365-3