Abstract

Ceramic matrix composites (CMCs) are promising materials for many high-technology engineering applications in harsh and severe environments due to their superior properties. However, in spite of all advantages, the employment of CMCs has been impeded by their high machining and finishing costs. Many of recently developed CMCs are very difficult to machine with the conventional machining technology, and improvement of the existing machining process is required and crucial. To overcome the existing technological constraints in the grinding of CMCs, a special designed block sonotrode was invented (and was registered for patent). The realization of ultrasonic-assisted machining on conventional machine tools can be carried out with much less effort by means of the new invented system. The invented block sonotrode is a specially designed perforated plate and demonstrates a multi-resonant frequency behavior. Experimental results illustrate the high performance of the presented method. A significant reduction in grinding forces and surface roughness and an increase in G-ratio have been achieved.

Similar content being viewed by others

References

Kazantsev VF (1979) Characteristic features of the plastic deformation of a material subjected to impact ultrasonic effects. AkustikaUl’trazvuk. Tekh., No. 15, pp 45–47

Markov AI (1980) Ultrasonic treatment of materials (in Russian). Mashinostroenie, Moscow

Nerubai MS (1987) Effect of ultrasonic vibrations on the mechanical properties of difficult-to-deform materials. Met Sci Heat Treat 29(4):254–258

Panin AV, Klimenov VA, Pochivalov YI, Son AA, Kazachenok MS (2004) The effect of ultrasonic treatment on mechanical behavior of titanium and steel specimens. Theor Appl Fract Mech 41:163–172

Severdenko P, Klubovichand VV, Stepanenko AV (1973) Pressure working of metals with ultrasound (in Russian). Nauka i Tekhnika, Minsk

Zhao B, Wu Y, Liu CS, Gaoand AH, Zhu XS (2006) The study on ductile removal mechanisms of ultrasonic vibration grinding nano-ZrO2 ceramics. Key Eng Mater 304–305:171–175

Zhao B, Wu Y, Jiao F, Gao GF, Zhu XS (2007) Experimental research on surface integrity of ceramic nanocomposites in two-dimensional ultrasonic vibration grinding. Key Eng Mater 329:445–450

Azarhoushang B, Tawakoli T (2009) Ultrasonicmachiningunit (in German), Deutsches Patent- und Markenamt, Aktenzeichen, 102009017248.3

Krenkel W (2008) Ceramic matrix composites. Wiley-VCH, Weinheim

Malkin S, Hwang T (1996) Grinding mechanisms for ceramics. Ann CIRP 45(2):569

Wagemann A (2001) Ceramic tools in metal forming (in German). Schmiedejournal

Li ZC, Jiao Y, Deines TW, Pei ZJ, Treadwell C (2005) Rotary ultrasonic machining of ceramic matrix composites: feasibility study and designed experiments. Int J Mach Tools Manuf 45:1402–1411

Tashiro T, Fujiwara J, Takenaka Y (2007) Grinding of C/C-SiC composite in dry method, in the book of towards synthesis of micro-/nano-systems, part 3. Springer, London, pp 351–352

Weinert K, Jansen T (2008) Machining aspects for the drilling of C/C-SiC materials. In: Krenkel W (ed) Ceramic matrix composites. Wiley-VCH, Weinheim, pp 287–301

Abdullah A, Pak A (2008) Correct prediction of the vibration behavior of the high power ultrasonic transducer by FEM simulation. Int J Adv Manuf Technol IJAMT 39(1–2):21–28

Azarhoushang B, Akbari J (2007) Ultrasonic-assisted drilling of Inconel 738-LC. Int J Mach Tools Manuf 47(7–8):1027–1033

Johnson DH, Pal D (2000) Simulation of an ultrasonic piezoelectric transducer. In: Proceedings of the 9th International ANSYS Conference, August 29

Prokic M (1997) A 1997 device for the generation of ultrasonic waves (in French). French patent application 2 743 929 (No d’enregistrement national: 9601029)

Prokic M (2001) Multifrequency ultrasonic structural actuator (MMM technology). European patent application, EP 1238715A1

Daus NA (2004) Ultrasonic assisted cross peripheral grinding (in German). Dissertation, Technische Universität Berlin

Tawakoliand T, Azarhoushang B (2008) Influence of ultrasonic vibrations on dry grinding of soft steel. Int J Mach Tools Manuf 48(14):1585–1591

Uhlmann E, Daus NA (2000) Ultrasonic assisted grinding—application advantages through an innovative grinding process (in German). BMBF-Abschlussbericht

Wu Y, Fan Y, Kato M, Kuriyagawa T, Syoji K, Tachibana T (2004) Development of an ultrasonic elliptic-vibration shoe centerless grinding technique. J Mater Process Technol 155–156:1780–1787

Cartsburg H (1993) Hard machining of ceramic composites (in German). Dissertation, Technische Universität Berlin

Qu W, Wang K, Miller MH, Huang Y, Chandra A (2000) Using vibration-assisted grinding to reduce subsurface damage. Precision Eng J 24:329–337

Frederick JR (1965) Ultrasonic engineering. Wiley, New York

Gordeev AV (1997) Wear resistance of segmental diamond wheels. Mach Tool (Eng translation Stanki Instrument) 48(2):21–22

Kim JD, Kang YH, Jin DX, Lee YS (1997) Development of discontinuous grinding wheel with multiporous grooves. Int J Mach Tools Manuf 37(11):1611–1624

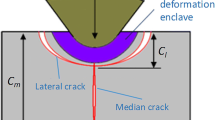

Lawn BR, Evans AG, Marshall DB (1980) Elastic/plastic indentation damage in ceramics: the median/radial crack system. J Am Ceram Soc 63(9–10):574–581

Evans AG, Wilshaw TR (1976) Quasi-plastic solid particle damage in brittle materials. Acta Metall 24:939–956

Brown RH, Saito K, Shaw MC (1971) Local elastic deflections in grinding. Ann CIRP 19:105–113

Yamada T, Lee HS (2005) Study on elastic deformations of grinding wheels due to centrifugal forces by means of the grinding wheels model consisting of abrasive grains and bonds. J Jpn Soc Abrasive Technol JSAT 49(10):576–581

Puw HY, Hocheng H (1999) Milling of polymer composites. In: Jahanmir S, Ramulu M, Koshy P (eds) Machining of ceramics and composites. CRC, Boca Raton, pp 267–294

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azarhoushang, B., Tawakoli, T. Development of a novel ultrasonic unit for grinding of ceramic matrix composites. Int J Adv Manuf Technol 57, 945–955 (2011). https://doi.org/10.1007/s00170-011-3347-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3347-x