Abstract

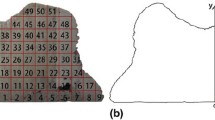

Present investigation pertains to analyse some aspect on the cold deformation behaviour of sintered silicon–copper steel preforms. The well-established phenomenon for raising the density in the powder metallurgy preform is to induce the extended strain. An attempt has been made to understand the attained densification as a function of new strain parameter \( {e^{{\varepsilon_z} - {\varepsilon_\theta }}} \), which results in a power law relationship. Further interest has shown to compare the conventional plastic Poisson’s ratio to instantaneous Poisson’s ratio, for which theoretical description were also made. This analysis shows some marginal difference between them; however, its characteristic nature is unique. In addition, various stresses that influence the deformation behaviour are also studied with respect to the induced axial strain.

Similar content being viewed by others

References

Andrej Šalak, Selecka M, Danninger H (2005) Machinability of powder metallurgy steels, 2nd edn. Cambridge Int Science Publishing, pp 63-73

Badawy A (1988) Survey and recommendations on the selection of optimum powder forging temperature. J Mater Shap Technol 6(1):31–40

Goto R (2003) Powder metallurgy growth in the automotive market. In: Business Briefing: Global Automotive Manufacturing and Technology. Materials, London, pp 44–45

Odhar RK, Pasha S (2003) Prediction of process parameter of metal powder preform using artificial neural network. J Mater Process Technol 132(1–3):227–234

Cho HK, Suh J, Kim KT (1994) Densification of porous alloy steel preforms at high temperature. Int J Mech Sci 36(4):317–328

Vamsi Krishna B, Sidhu RK (2002) Analysis of center burst during hot forging. J Fail Anal and Preven 2(5):61–66

Narayanasamy R, Senthilkumar V, Pandey KS (2008) Some features on hot forging of powder metallurgy sintered high strength 4%titanium carbide composite steel preforms under different stress state conditions. Mater Des 29(7):1380–1400

Zhang XQ, Peng YH, Ruan XY, Li MQ, Wu SC (2000) Study of workability limits of porous materials under different upsetting conditions by compressible rigid plastic element method. J of Materi Eng and Perform 9(2):164–169

Rajeshkannan A, Pandey KS, Shanmugam S (2006) Some studies on barreling of powder preforms during cold upsetting. J Mech Behav Mater 17(6):415–430

Anderson JC, Leavers KD, Leevers P, Rawlings RD (2003) Materials science for engineers, 5th edn. Nelson Thornes, UK, pp 212–217

Hua L, Qin X, Mao H, Zhao Y (2006) Plastic deformation and yield criterion for compressible sintered powder materials. J Mater Process Technol 180(1–3):174–178

Lawley A (1982) Advances in powder technology, 1981. In: Chin GY (ed) ASM materials science seminar. ASM, New York

McCormac JC (2008) Structural steel design, 4th edn. Prentice Hall, pp 1-34

Shanmugasundaram D, Chandramouli R, Kandavel TK (2009) Cold and hot deformation and densification studies on sintered Fe-C-Cr-Ni low alloy P/M steels. Int J Adv Manuf Technol 41(1–2):8–15

Moyer KH (1979) Measuring density of P/M materials with improved precision. Int J Powder Metall Powder Technol 15:33–42

Narayanasamy R, Pandey KS (1990) Some aspects of barreling of porous solid cylinders under axial compression. Powder Metall Sci Technol 1(2):24–34

El Wakil SD (1984) On the work hardening of sintered porous materials, Proc. Of 12th North American Manufacturing Research Conference, p 86

Rajeshkannan A, Pandey KS, Shanmugam S, Narayanasamy R (2008) Deformation behaviour of sintered high carbon alloy powder metallurgy steel in powder preform forging. Mater Des 29:1862–1867

Rajeshkannan A, Pandey KS, Shanmugam S (2008) Some investigation on the cold deformation behaviour of sintered iron–0.8% carbon alloy powder preforms. J Mater Process Technol 203:542–547

Kandavel TK, Chandramouli R, Shanmugasundram D (2009) Experimental study of the plastic deformation and densification behaviour of some sintered low alloy P/M steels. Mater Des 30(5):1768–1776

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ananthanarayanan, R. Deformation behaviour of sintered silicon–copper steel preforms of various aspect ratios during cold upsetting. Int J Adv Manuf Technol 50, 509–515 (2010). https://doi.org/10.1007/s00170-010-2544-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2544-3