Abstract

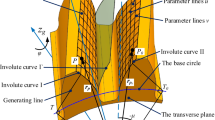

The envelope theory provides a solid mathematical tool for accurate computations and design of milling tools that generate helical surfaces such as disk or end mill tools. Given an analytical description of the helical surface to be generated, and considering that the machined surface and milling tools are reciprocally enwrapping during the generation motions, one can deduce equations for the milling tool profile. However, this usually involves transcendent equations that require significant computational resources for their solution. More importantly, analytical representations of the surfaces to be generated are not always available, as in the case of measured discrete surfaces. To alleviate the issue, polynomial approximations of the entire helical surface or only of a spatial curve along the surface can be used as already published in previous works. The present study focuses on the methodology of finding the simplest polynomials when only a small number of points are known or measured from the surface to be generated. The numerical simulation and real examples show that third degree Bezier polynomials are suitable approximations for many practical situations. In such cases, not only computation complexity is highly reduced but also the measurement process is significantly simplified. The paper presents a methodology for the design of disk-cutting tools reciprocally enwrapping cylindrical helical surfaces of constant pitch when the helical surface generatrix is known in discrete form. The suggested method is using a small number of points belonging to the helical surface to be machined. Due to the use of a low-order Bezier polynomials representation of the helical surface generatrix, a small approximation error is introduced as shown in our numerical examples. Using as a reference the analytical representation of the generatrix, the exact axial section of the disk tool can be computed and compared to the axial section obtained using the methodology described in this paper. The approximation errors seem to be acceptable for many technical applications. Numerical simulations and examples were performed using a Java-based implementation of the suggested algorithm.

Similar content being viewed by others

References

Anish P, Kapoor SG, De Vor RE (2005) A chiesel edge model for arbitrary drill point geometry. J Manuf Sci Eng 127:23–32

Favrolles JP (1998) Les surfaces complexes. Hermes, Paris

Hsieh JF, Lin PD (2005) Drill point geometry of multi-flute drills. Int J Adv Manuf Technol 26:466–476

Kaharaman A, Bajpai P, Anderson NE (2005) Influence of tooth profile deviations on helical gear wear. J Mech Des 127:656–663

Litvin FL (1984) Theory of gearing. NASA, Scientific and Technical Information Division, Washington DC

Oancea N (1996) Méthode numérique pour l’étude des surfaces enveloppées. Mech Mach Theory 31(7):954–972

Teodor V et al (2003) Method of generation trajectories. comparision between the Gohman method and the method of trajectories generation. The Annals of “Dunarea de Jos” University of Galati, Fascicle V, ISSN 1221-4566, year XXI(XXVI), pp 12–20

Sun Y, Wang J, Guo D, Zhang Q (2006) Modeling and numerical simulation for the machining of helical surfaces profiles on cutting tools. Int J Adv Manuf Technol 36:525–534. doi:10.1007/s00170-006-0860-4

Guanghui Z, Jing W, Li-Ming W (2007) Study on manufacturing theory of helicoids based on discrete points (abstract). China Mech Eng 18(10):1178–1182

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oancea, N., Popa, I., Teodor, V.G. et al. Tool profiling for generation of discrete helical surfaces. Int J Adv Manuf Technol 50, 37–46 (2010). https://doi.org/10.1007/s00170-009-2492-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2492-y