Abstract

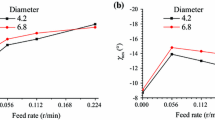

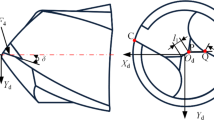

This paper presents a comprehensive mathematical model for analysis of the geometries of conical, hyperboloidal, and ellipsoidal drills. The proposed method includes three particular features. The first is that a rotational disk-type abrasive wheel is modeled by revolution geometry, thus allowing for the normal and tangent vectors of an abrasive wheel to be obtained explicitly. Consequently, the tangent and normal vectors along the cutting edges and chisel edges of the produced drill can be obtained. The second feature is the ability of the model to determine and express drill geometries and characteristics (semi-point angle, tool cutting edge inclination, chisel angle, normal rake angle and normal clearance angle) according to all current international standards. Thirdly, the drill’s working geometries are investigated by taking the effect of feed motion into consideration. We found that cutting edge geometry can be studied without significant error even though we neglect the effect of feed. The chisel edge working geometry shows greater variation than tool geometry. Consequently, the effect of feed must be taken into consideration when studying chisel edge action during drilling operation.

Similar content being viewed by others

References

Ema S, Fujii H, Marui E, Kato S (1988) New type drill with three major cutting edges. Int J Mach Tools Des Res 28:461–473

Ema S, Fujii H, Marui E (1991) Cutting performance of drills with three cutting edges: effects of chisel edge shapes on the cutting performance. Int J Mach Tools Manuf 31:361–369

Agapiou JS (1993) Design characteristics of new types of drill and evaluation of their performance drilling cast iron II: drills with four major cutting edges. Int J Mach Tools Manuf 33:321–341

Agapiou, JS (1993) Design characteristics of new types of drill and evaluation of their performance drilling cast iron II: drills with three major cutting edges. Int J Mach Tools Manuf 33:343–365

Oxford CJ (1955) On the drilling of metals 1: basic mechanics of the process. Trans ASME 77:103–114

Galloway DF (1957) Some experiments on the influence of various factors on drill performance. Trans ASME 79:191–231

Fujii S, DeVries MF, Wu SM (1970) An analysis of drill geometry for optimum drill design by computer 1: drill geometry analysis. J Eng Ind Trans ASME 92:647–656

Fujii S, DeVries MF, Wu SM (1971) An analysis of the chisel edge and the effect of the d-theta relationship on drill point geometry. J Eng Ind Trans ASME 93:1093–1105

Armarego EJA, Rotenberg A (1973) An investigation of drill point sharpening by the straight lip conical grinding method 1: basic analysis. Int J Mach Tool Des Res 13:155–164

Armarego EJA, Rotenberg A (1973) An investigation of drill point sharpening by the straight lip conical grinding method 2: a criterion for selecting a solution. Int J Mach Tool Des Res 13:165–182

Tasi WD, Wu SM (1979) Computer analysis of drill point geometry. Int J Mach Tools Des Res 19:95–108

Watson, AR (1985) Geometry of drill elements. Int J Mach Tools Des Res 25:209–227

Salama AS, ElSawy AH (1996) The dynamic geometry of a twist drill point. Int J Mater Process Technol 65:45–53

Hsieh JF, Lin PD (2002) Mathematical model of multi-flute drill point. Int J Mach Tools Manuf 42:1181–1193

Boothroyd G (1975) Fundamentals of metal machining and machine tools. McGraw-Hill, New York

Lin C, Kang SK, Ehmann KF (1995) Helical micro-drill point design and grinding. ASME J Eng Ind 117:277–287

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsieh, JF., Lin, P. Drill point geometry of multi-flute drills. Int J Adv Manuf Technol 26, 466–476 (2005). https://doi.org/10.1007/s00170-003-2027-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-2027-x