Abstract

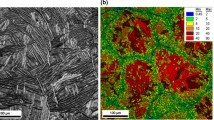

The wall thickness of hydro-formed micro-tubes is not uniform due to the low ratio of the wall thickness and the grain size. The features of localised thinning are different from those of the traditional hydroforming process, and this is related directly to the ratio of the wall thickness and the grain size of the material, and also to the amount of deformation. Macro-mechanics finite element (FE) modelling cannot be used to simulate such effects encountered in micro-tube hydroforming processes. In this paper, a simplified plane-strain crystal-plasticity finite element (CPFE)-based modelling technique has been developed and used to capture the localised thinning features in the hydroforming of micro-tubes. The grain structures within the tube workpiece, and their distributions and orientations, are generated automatically using the developed VGRAIN system. A set of crystal-viscoplasticity models is implemented in ABAQUS/Explicit FE code through the user-defined sub-routine, VUMAT. Single-crystal and multi-crystal structures have been studied, and the localised thinning has been analysed for different microstructures of the material using the CPFE modelling technique. It is confirmed from the analysis that the localised thinning in the hydroforming of micro-tubes is affected significantly by the microstructure and grain orientations of the material.

Similar content being viewed by others

References

Ahmetoglu M, Altan T (2000) Tube hydroforming. State of the art and future trends. J Mater Process Technol 98:25. doi:10.1016/S0924-0136(99)00302-7

Hart C (2005) Research and advances in fundamentals and industrial applications of hydroforming. J Mater Process Technol 167:283–392. doi:10.1016/j.jmatprotec.2005.06.053

Aue-u-lan Y, Ngaile G, Altan T (2004) Optimizing tube hydroforming using process simulation and experimental verification. J Mater Process Technol 146:137–143. doi:10.1016/S0924-0136(03)00854-9

Kim J, Kim WJ, Kang BS (2005) Analytical and numerical approach to prediction of forming limit in tube hydroforming. Int J Mech Sci 47:1023–1037. doi:10.1016/j.ijmecsci.2005.02.011

Kang SJ, Kim HK, Kang BS (2005) Size effect on hydroforming formability. J Mater Process Technol 160:24–33. doi:10.1016/j.jmatprotec.2004.02.035

Zamiri A, Pourboghrat F, Barlat F (2007) An effective computational algorithm for rate-independent crystal plasticity based on a single crystal yield surface with an application to tube hydroforming. Int J Plast 23:1126–1147. doi:10.1016/j.ijplas.2006.10.012

Jansson M, Nilsson L, Simonsson K (2008) Tube hydroforming of aluminium extrusions using a conical die and extensive feeding. J Mater Process Technol 198:14–21. doi:10.1016/j.jmatprotec.2007.09.043

Taylor GI (1938) Plastic strains in metals. J Inst Met 62:307–324

Hill R, Rice JR (1972) Constitutive analysis of elastic–plastic crystals at arbitrary strain. J Mech Phys Solids 20:401–413. doi:10.1016/0022-5096(72)90017-8

Asaro RJ (1983) Crystal plasticity. J Appl Mech 50:921–934

Peirce D, Asaro RJ, Needleman A (1982) Material rate dependence and localized deformation in crystalline solids. Acta Metall 31:1951–1976. doi:10.1016/0001-6160(83)90014-7

Harewood FJ, McHugh PE (2007) Comparison of the implicit and explicit finite element methods using crystal plasticity. Comput Mater Sci 39:481–494. doi:10.1016/j.commatsci.2006.08.002

Ho KC, Zhang N, Lin J Dean, T.A. (2007) An integrated approach for virtual microstructure generation and micromechanics modelling for micro-forming simulation, Proceedings of ASME, MNC2007, Pitchumani, R., MicroNanoChina07, Sanya, Hainan, 10–13 January 2007.

Cao J, Zhuang W, Wang S, Ho KC, Zhang N, Lin J, Dean TA (2009) An integrated crystal plasticity FE system for microforming simulation. J Multiscale Model 1(1):107–124. doi:10.1142/S1756973709000037

Huang Y (1991) A user-material subroutine incorporating single crystal plasticity in the ABAQUS finite element program. Harvard University Report, MECH 178

Kutt LM, Pifko AB, Nardiello JA, Papazian JM (1998) Slow-dynamic finite element simulation of manufacturing processes. Comput Struct 66:1–17. doi:10.1016/S0045-7949(97)00069-2

Chung WJ, Cho JW, Belytschko T (1998) On the dynamic effects of explicit FEM in sheet metal forming analysis. Eng Comput 15:750–776. doi:10.1108/02644409810231880

Choi H-H, Hwang S-M, Kang YH, Kim J, Kang BS (2002) Comparison of implicit and explicit finite element methods for the hydroforming process of an automobile lower arm. Int J Adv Manuf Technol 20:407–413. doi:10.1007/s001700200170

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhuang, W., Wang, S., Cao, J. et al. Modelling of localised thinning features in the hydroforming of micro-tubes using the crystal-plasticity FE method. Int J Adv Manuf Technol 47, 859–865 (2010). https://doi.org/10.1007/s00170-009-2134-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2134-4