Abstract

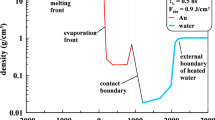

Laser shock processing during high-intensity beam ablation of the metallic surface is examined. The phase change due to evaporation and melting is modeled using an energy method. The vapor front expansion and pressure build-up in the laser-produced cavity are obtained numerically using a control volume approach. Elasto-plastic response of the substrate material due to mechanical loading of pressure field developed in the cavity is modeled and predicted using a finite element method. It is found that a high-pressure region is developed in the vicinity of the cavity edge, which, in turn, results in excessive stresses and plastic strain in this region. The depth of the plastic region in the order of a few micrometers below the surface is predicted.

Similar content being viewed by others

References

Yilbas BS, Naqavi IZ, Shuja SZ (2002) Modeling and experimental study into the laser-assisted nitriding of Ti–6Al–4V. ASME. J Manuf Sci Eng 124:863–874 doi:10.1115/1.1511171

Yilbas BS (2003) Laser shortpulse heating of gold: variable properties case. Int J Heat Mass Transfer 46:3511–3520 doi:10.1016/S0017-9310(03)00131-5

Montross CS, Wei T, Ye L, Clark G, Mai YW (2002) Laser shock processing and its effects on microstructure and properties of metal alloy: a review. Int J Fatigue 24:1021–1036 doi:10.1016/S0142-1123(02)00022-1

Thorslund T, Kahlen FJ, Kar A (2003) Temperatures, pressures and stresses during laser shock processing. Opt Lasers Eng 39:51–71 doi:10.1016/S0143-8166(02)00040-4

Senecha VK, Zhang J, Wang W, Pant HC (2002) Numerical simulation study of laser-driven shock wave propagation in planar aluminium foils. J Phys Condens Matter 14:10917–10920 doi:10.1088/0953-8984/14/44/401

Ding K, Ye L (2003) Three-dimensional dynamic finite element analysis of multiple laser shock peening processes. Surf Eng 19(5):351–358 doi:10.1179/026708403225007563

Yin S, Zhang Y, Zhou J, Yang J (2005) Movement control of forming by laser shock wave. Proc SPIE-Int Soc Opt Eng 6043 I, MIPPR 2005: SAR and Multispectral Image Processing

Berthe L, Fabbro R, Peyre P, Bartnicki E (1997) Laser shock processing of materials: Experimental study of breakdown plasma effects at the surface of confining water. Proc SPIE-The Int Soc Opt Eng 3097:570–575

Chen JP, Ni XW, Lu J, Bian BM, Wang YW (2000) Laser-induced plasma shock wave and cavity on metal surface underwater. Microw Opt Technol Lett 25(5):307–311 doi:10.1002/(SICI)1098-2760(20000605)25:5<307::AID-MOP6>3.0.CO;2-1

Faraggi E, Wang S, Gerstman B (2005) Stress confinement, shock wave formation and laser induced damage. Progress in Biomedical Optics and Imaging-Proceedings of SPIE, Vol. 5695, Optical Interactions with Tissue and Cells XVI, 2005, pp. 209–215.

Schmidt-Uhlig T, Karlitschek P, Yoda M, Sano Y, Marowsky G (2000) Laser shock processing with 20 MW laser pulses delivered by optical fibres. EPJ Appl Phys 9(3):235–238 doi:10.1051/epjap:2000109

Zhang Y, Cai L, Yang J, Ren N (1997) Measurements of laser-induced shock pressures using PVDF transducer. Chin J Lasers B B6(1):81–85 English Edition

Yilbas BS, Gondal MA, Arif AMF, Shuja SZ (2004) Laser shock processing of Ti–6Al–4V alloy. Proc I MECH E Part B, J Eng Manuf 218(5):473–482

Yilbas BS, Naqavi IZ (2003) Laser heating including phase change process and thermal stress generation in relation to drilling. Proc Instn Mech Engrs Part B: J Eng Manuf 217:977–991

Yilbas BS, Naqavi I (2006) Laser heating and thermal stresses time exponentially heating pulse case. Trans Can Soc Mech Eng 30:113–142

Mansoor SB (2006) Laser evaporative heating in relation to machining, M.Sc. Thesis, Mech. Eng. Dept., KFUPM

Naqavi IZ (2001) Conduction and non-conduction limited laser heating process—mathematical simulation, M.Sc. Thesis, Mech. Eng. Dept., KFUPM

Patankar SV (1980) Numerical heat transfer. McGraw-Hill, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yilbas, B.S., Mansoor, S.B. & Arif, A.F.M. Laser shock processing: modeling of evaporation and pressure field developed in the laser-produced cavity. Int J Adv Manuf Technol 42, 250–262 (2009). https://doi.org/10.1007/s00170-008-1601-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1601-7