Abstract

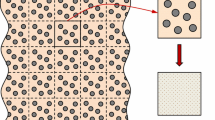

A two-scale material modeling approach is adopted in order to determine macroscopic thermal and elastic constitutive laws and the respective parameters for metal matrix composite (MMC). Since the common homogenization framework violates the thermodynamical consistency for non-constant temperature fields, i.e., the dissipation is not conserved through the scale transition, the respective error is calculated numerically in order to prove the applicability of the homogenization method. The thermomechanical homogenization is applied to compute the macroscopic mass density, thermal expansion, elasticity, heat capacity and thermal conductivity for two specific MMCs, i.e., aluminum alloy Al2024 reinforced with 17 or 30 % silicon carbide particles. The temperature dependency of the material properties has been considered in the range from 0 to \(500{\,}^\circ \mathrm {C}\), the melting temperature of the alloy. The numerically determined material properties are validated with experimental data from the literature as far as possible.

Similar content being viewed by others

References

Asad, M., Girardin, F., Mabrouki, T., Rigal, J.F.: Dry cutting study of an aluminium alloy (A2024-T351): a numerical and experimental approach. Int. J. Mater. Form. 1, 499–502 (2008)

Böhm, H.J., Rasool, A.: Effects of particle shape on the thermoelastoplastic behavior of particle reinforced composites. Int. J. Solids Struct. 87, 90–101 (2016). doi:10.1016/j.ijsolstr.2016.02.028

Böhm, H.J.: A short introduction to basic aspects of continuum micromechanics. Technical Report, CDLFMD Report, 020624, 31998 (1998)

Böhm, H.J., Rammerstorfer, F.G., Weissenbek, E.: Some simple models for micromechanical investigations of fiber arrangement effects in MMCs. Comput. Mater. Sci. 1(3), 177–194 (1993). doi:10.1016/0927-0256(93)90010-K

Brammer, J.A., Percival, C.M.: Elevated-temperature elastic moduli of 2024 aluminum obtained by a laser-pulse technique. Exp. Mech. 10(6), 245–250 (1970)

Budiansky, B.: Thermal and thermoelastic properties of isotropic composites. J. Compos. Mater. 4(3), 286–295 (1970). doi:10.1177/002199837000400301

Dirrenberger, J., Forest, S., Jeulin, D.: Elastoplasticity of auxetic materials. Comput. Mater. Sci. 64, 57–61 (2012). doi:10.1016/j.commatsci.2012.03.036

Fillep, S., Mergheim, J., Steinmann, P.: Computational modelling and homogenization of technical textiles. Eng. Struct. 50, 68–73 (2013)

Fritzen, F., Forest, S., Kondo, D., Böhlke, T.: Computational homogenization of porous materials of green type. Comput. Mech. 52(1), 121–134 (2013). doi:10.1007/s00466-012-0801-z

Han, W., Eckschlager, A., Böhm, H.J.: The effects of three-dimensional multi-particle arrangements on the mechanical behavior and damage initiation of particle-reinforced mmcs. Compos. Sci. Technol. 61(11), 1581–1590 (2001). doi:10.1016/S0266-3538(01)00061-6

Hasselman, D., Johnson, L.: Effective thermal conductivity of composites with interfacial thermal barrier resistance. J. Compos. Mater. 21(6), 508–515 (1987). doi:10.1177/002199838702100602. Cited By 657

Haupt, P.: Continuum Mechanics and Theory of Materials, Advanced Texts in Physics. Springer, Berlin (2002)

Hill, R.: Elastic properties of reinforced solids: some theoretical principles. J. Mech. Phys. Solids 11(5), 357–372 (1963)

Holzapfel, G.A.: Nonlinear Solid Mechanics—A Continuum Approach for Engineering. Wiley, Chichester (2000)

Javili, A., McBride, A., Mergheim, J., Steinmann, P., Schmidt, U.: Micro-to-macro transitions for continua with surface structure at the microscale. Int. J. Solids Struct. 50(2), 2561–2572 (2013)

Kanit, T., Forest, S., Galliet, I., Mounoury, V., Jeulin, D.: Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int. J. Solids Struct. 40(13–14), 3647–3679 (2003)

Mandel, J.: Contribution téorique à l’étude de l’écrouissage et des lois de l’écoulement plastique. In: Görtler, H. (ed.) Applied Mechanics: Proceedings of the Eleventh International Congress of Applied Mechanics Munich (Germany), pp. 502–509 (1966)

Mangipudi, K., Onck, P.: Multiscale modelling of damage and failure in two-dimensional metallic foams. J. Mech. Phys. Solids 59(7), 1437–1461 (2011). doi:10.1016/j.jmps.2011.02.008

Moakher, M., Norris, A.N.: The closest elastic tensor of arbitrary symmetry to an elasticity tensor of lower symmetry. J. Elast. 85(3), 215–263 (2006). doi:10.1007/s10659-006-9082-0

Munro, R.G.: Materials properties of a sintered \(\alpha \)-SiC. J. Phys. Chem. Ref. Data 26(5), 1195–1203 (1997)

Nguyen, V.D., Béchet, E., Geuzaine, C., Noels, L.: Imposing periodic boundary condition on arbitrary meshes by polynomial interpolation. Comput. Mater. Sci. 55, 390–406 (2012)

Ottosen, N., Ristinmaa, M.: The Mechanics of Constitutive Modeling. Elsevier Science, Amsterdam (2005)

Pfaller, S., Rahimi, M., Possart, G., Steinmann, P., Müller-Plathe, F., Böhm, M.C.: An arlequin-based method to couple molecular dynamics and finite element simulations of amorphous polymers and nanocomposites. Comput. Methods Appl. Mech. Eng. 260, 109–129 (2013)

Reuss, A.: Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle. J. Appl. Math. Mech. 9(1), 49–58 (1929). doi:10.1002/zamm.19290090104

Roters, F., Eisenlohr, P., Hantcherli, L., Tjahjanto, D., Bieler, T., Raabe, D.: Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: theory, experiments, applications. Acta Mater. 58(4), 1152–1211 (2010). doi:10.1016/j.actamat.2009.10.058

Shilkrot, L., Miller, R., Curtin, W.: Multiscale plasticity modeling: coupled atomistics and discrete dislocation mechanics. J. Mech. Phys. Solids 52(4), 755–787 (2004). doi:10.1016/j.jmps.2003.09.023

Song, M.: Effects of volume fraction of SiC particles on mechanical properties of SiC/Al composites. Trans. Nonferrous Metals Soc. China (English Edition) 19(6), 1400–1404 (2009). doi:10.1016/S1003-6326(09)60040-6

Tadmor, E.B., Miller, R.E.: Modeling Materials: Continuum, Atomistic and Multiscale Techniques. Cambridge University Press, Cambridge (2011)

Temizer, I., Wriggers, P.: Homogenization in finite thermoelasticity. J. Mech. Phys. Solids 59(2), 344–372 (2011). doi:10.1016/j.jmps.2010.10.004

Voigt, W.: Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper. Ann. Phys. 274(12), 573–587 (1889). doi:10.1002/andp.18892741206

Zhao, N., Yang, Yq, Han, M., Luo, X., Feng, Gh, Zhang, Rj: Finite element analysis of pressure on 2024 aluminum alloy created during restricting expansion-deformation heat-treatment. Trans. Nonferrous Met. Soc. China 22, 2226–2232 (2012)

Ziegler, T., Neubrand, A., Piat, R.: Multiscale homogenization models for the elastic behaviour of metal/ceramic composites with lamellar domains. Compos. Sci. Technol. 70(4), 664–670 (2010). doi:10.1016/j.compscitech.2009.12.022

Acknowledgments

The authors would like to thank the German research foundation (DFG) for funding the project “Thermal effects when turning Al-MMC—experiments and simulations AU 185/26, STE 544/42” within the priority program SPP 1480.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Rights and permissions

About this article

Cite this article

Schindler, S., Mergheim, J., Zimmermann, M. et al. Numerical homogenization of elastic and thermal material properties for metal matrix composites (MMC). Continuum Mech. Thermodyn. 29, 51–75 (2017). https://doi.org/10.1007/s00161-016-0515-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-016-0515-0