Abstract

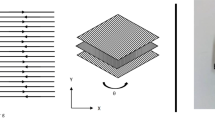

The stress state is an important parameter in metal forming processes, which significantly influences the strain state and microstructure of products, affecting their surface qualities. In order to make the metal products have a good surface quality, the surface stress state must be optimised. In this study, two classical methods, the upper bound method and the crystal plasticity finite element method, were investigated. The differences between the two methods were discussed in regard to the model, the velocity field, and the strain field. Then the related surface roughness is deduced.

Similar content being viewed by others

References

Degarmo E.P., Black J.T., Kohser R.A.: Materials and Processes in Manufacturing (9th ed.). Wiley, New York (2003)

Osakada K., Oyane M.: On the roughing of free surface in deformation process. Bull. JSME 14, 171–177 (1971)

Tokizawa M., Yosikawa Y.: The mechanism of lubricant trapping under the cold compression of metals. J. Jpn. Inst. Met. 37, 19–25 (1973)

Chen G., Shen H., Hu S., Baudelet B.: Roughening of the free surfaces of metallic sheets during stretching forming. Mat. Sci. Eng A. 128, 33–38 (1990)

Becker R.: Effect of strain localization on surface roughening during sheet forming. Acta Mater. 46, 1385–1401 (1998)

Stoudt M.R., Ricker R.E.: The relationship between grain size and the surface roughening behaviour of Al–Mg alloys. Mater. Trans. A. 33, 2883–2889 (2002)

Sheu S., Wilson W.R.D.: Flattening of work piece surface asperities in Metal forming. Proc NAMRC XI, 172–178 (1983)

Wilson W.R.D., Lee W.M.: Mechanics of surface roughening in metal forming process. J. Manuf. Sci. Eng. 123, 279–283 (2001)

Makinouchi A., Ike H., Murakawa M., Koga N.: A finite element analysis of flattening of surface asperities by perfectly lubricated rigid dies in metal working processes. Wear 128, 109–122 (1988)

Sutcliffe M.P.F.: Surface asperity deformation in metal forming processes. Int. J. Mech. Sci. 11, 847–868 (1988)

Dieter G.E.: Mech, Metall. 3rd. McGraw-Hill, New York, NY (1986)

Wilson W.R.D.: Tribology in Cold Metal Forming. J. Manu. Sci. Eng. 119, 695–698 (1997)

Groche P., Schafer R., Justinger H., Ludwig M.: On the correlation between crystallographic grain size and surface evolution in metal forming processes. Int. J. Mech. Sci. 52, 523–530 (2010)

Groche, P., Schafer, R., Henning, M.: Finite element calculation of surface Evolution considering grain size and crystallographic texture effects, Proceedings of ICTMP2007.Yokohama: Yokohama National University, 219–226 (2007)

Nagpal Vijay.: A lower upper-bound approach to some metal forming problems, Ph.D Thesis, Georgia Institute of Technology (1974)

Bramley A.N., Osman F.H.: Numerical modelling of material deformation processes. Springer, London (1992)

Asaro R.J., Needleman A.: Texture development and strain hardening in rate dependent polycrystals. Acta Mater. 33, 923–953 (1985)

Hill R., Rice J.R.: Constitutive analysis of elastic-plastic crystals at arbitrary strain. J. Mech. Phys. Solids. 20, 401–413 (1972)

Pierce D., Asaro R.J., Needleman A.: An analysis of non-uniform and localized deformation in ductile single crystals. Acta Mater. 30, 1087–1119 (1982)

Kroner E.: On the plastic deformation of polycrystals. Acta Mater. 9, 155–161 (1961)

Kroner E.: Kontinuumstheorie der Versetzungen und Eigenspannungen. Springer, Berlin (1958)

Kroner, E.: In: Physics of defects. Amsterdam: North-Holland Publishing Company (1981)

Kroner E.: Allgemeine Kontinuumstheorie der Versetzungen und Eigenspannungen. Arch. Ration Mech. Anal. 4, 273–334 (1959)

Lee E.H., Liu D.T.: Finite-strain elastic-plastic theory with application to plane-wave analysis. J. Appl. Phys. 38, 19–27 (1967)

Li, H.J.: A study of surface roughness in the metal forming process, Ph.D Thesis, UOW (2012)

Li H.J., Jiang Z.Y., Wei D.B.: Crystal plasticity finite modelling of 3D surface asperity flattening in uniaxial planar compression. Tribol. Lett. 46, 101–112 (2012)

Ebrahimi R., Reihanian M., Kanaani M., Moshksar M.M.: An upper-bound analysis of the tube extrusion process. J. Mater. Process. Technol. 199, 214–220 (2008)

Komori K.: An upper bound method for analysis of three-dimensional deformation in the flatting rolling of bars. Int. J. Mech. Sci. 44, 37–55 (2002)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Rights and permissions

About this article

Cite this article

Li, H., Öchsner, A., Ni, G. et al. Analysis of surface asperity flattening based on two different methods. Continuum Mech. Thermodyn. 28, 1623–1634 (2016). https://doi.org/10.1007/s00161-016-0496-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-016-0496-z