Abstract

Design of multiscale structures is a challenging task due to a vast design space of both materials and structures. Consideration of load uncertainty adds another level of complexity. In this paper, a robust concurrent TO (topology optimization) approach is developed for designing multiscale structures composed of multiple porous materials under random field loading uncertainty. To determine the optimal distribution of the porous materials at the macro/structural scale, our key idea is to employ the discrete material optimization method to interpolate the material properties for multiple porous materials. In addition, for the first time we interpret the interpolation schemes in the existing concurrent TO model of porous material with a clear physical meaning by putting forward a SIMP-like single interpolation scheme. This scheme integrates the SIMP (Solid Isotropic Material with Penalization) at the microscale and PAMP (Porous Anisotropic Material with Penalization) at the macroscale into a single equation. Efficient uncertainty characterization and propagation methods based on K-L expansion and linear superposition are introduced, and several important improvements in objective function evaluation and sensitivity analysis are presented. Improved sensitivity analysis equations are derived for volume preserving filtering, which is employed to deal with numerical instabilities at the macro and micro scales in the robust concurrent TO model. Measures to ensure manufacturability and to improve analysis accuracy and efficiency are devised. 2D and 3D examples demonstrate the effectiveness of the proposed approach in simultaneously obtaining robust optimal macro structural topology and material microstructural topologies.

Similar content being viewed by others

References

Amir O, Sigmund O (2011) On reducing computational effort in topology optimization: how far can we go? Struct Multidiscip Optim 44(1):25–29

Bendsøe MP (1989) Optimal shape design as a material distribution problem. Struct optim 1(4):193–202

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71(2):197–224

Bendsoe MP, Sigmund O (1999) Material interpolation schemes in topology optimization. Arch Appl Mech 69(9–10):635–654

Bendsoe MP, Guedes JM, Haber RB, Pedersen P, Taylor JE (1994) An analytical model to predict optimal material properties in the context of optimal structural design. J Appl Mech Transactions of the Asme 61(4):930–937

Bensoussan A, Lions JL, Papanicolaou G (1978) Asymptotic analysis for periodic structures. (Vol. 5) Amsterdam: North-Holland Publishing Company

Bourdin B (2001) Filters in topology optimization. Int J Numer Methods Eng 50(9):2143–2158

Bruns TE, Tortorelli DA (2001) Topology optimization of non-linear elastic structures and compliant mechanisms. Comput Methods Appl Mech Eng 190(26):3443–3459

Chen SK, Chen W, Lee SH (2010) Level set based robust shape and topology optimization under random field uncertainties. Struct Multidiscip Optim 41(4):507–524

Cheng K-T, Olhoff N (1981) An investigation concerning optimal design of solid elastic plates. Int J Solids Struct 17(3):305–323

Deng J, Yan J, Cheng G (2011) Thermo-mechanical coupling topology optimization of structures composed of optimal homogeneous ultra-light porous materials. In: 9th World Congress on Structural and Multidisciplinary Optimization. Shizuoka, Japan

Deng J, Yan J, Cheng G (2013) Multi-objective concurrent topology optimization of thermoelastic structures composed of homogeneous porous material. Struct Multidiscip Optim 47(4):583–597

Duan Z, Yan J, Zhao G (2015) Integrated optimization of the material and structure of composites based on the Heaviside penalization of discrete material model. Structural and Multidisciplinary Optimization 51(3):721-732

Dunning PD, Kim HA (2013) Robust topology optimization: minimization of expected and variance of compliance. AIAA J 51(11):2656–2664

Dunning PD, Kim HA, Mullineux G (2011) Introducing loading uncertainty in topology optimization. AIAA J 49(4):760–768

Guedes JM, Lubrano E, Rodrigues HC, Turteltaub S (2006) Hierarchical optimization of material and structure for thermal transient problems. In: IUTAM Symposium on Topological Design Optimization of Structures, Machines and Materials. Springer Netherlands 527-536

Guest JK, Prévost JH, Belytschko T (2004) Achieving minimum length scale in topology optimization using nodal design variables and projection functions. Int J Numer Methods Eng 61(2):238–254

Guo X, Zhao X, Zhang W, Yan J, Sun G (2015) Multi-scale robust design and optimization considering load uncertainties. Comput Methods Appl Mech Eng 283:994–1009

Hestenes MR, Stiefel E (1952). Methods of conjugate gradients for solving linear systems, NBS. 49:1

Lee SH, Chen W (2009) A comparative study of uncertainty propagation methods for black-box-type problems. Struct Multidiscip Optim 37(3):239–253

Liu ST, Cheng GD, Gu Y, Zheng XG (2002) Mapping method for sensitivity analysis of composite material property. Struct Multidiscip Optim 24(3):212–217

Liu L, Yan J, Cheng GD (2008) Optimum structure with homogeneous optimum truss-like material. Comput Struct 86(13–14):1417–1425

Niu B, Yan J, Cheng GD (2009) Optimum structure with homogeneous optimum cellular material for maximum fundamental frequency. Struct Multidiscip Optim 39(2):115–132

Patzak B, Bittnar Z (2001) Design of object oriented finite element code. Adv Eng Softw 32(10–11):759–767

Ringertz UT (1993) On finding the optimal distribution of material properties. Struct Optim 5(4):265–267

Rodrigues H, Guedes JM, Bendsoe MP (2002) Hierarchical optimization of material and structure. Struct Multidiscip Optim 24(1):1–10

Schury F (2012) Two-Scale Material Design - From Theory to Practice. PhD, University of Erlangen-Nuremberg

Schury F, Stingl M, Wein F (2012) Efficient two-scale optimization of Manufacturable graded structures. SIAM J Sci Comput 34(6):B711–B733

Sigmund O (2007) Morphology-based black and white filters for topology optimization. Struct Multidiscip Optim 33(4–5):401–424

Sigmund O, Torquato S (1997) Design of materials with extreme thermal expansion using a three-phase topology optimization method. Journal of the Mechanics and Physics of Solids 45(6):1037-1067

Sivapuram R, Dunning PD, Kim HA (2016) Simultaneous material and structural optimization by multiscale topology optimization. Struct Multidiscip Optim 54(5):1267–1281

Stegmann J, Lund E (2005) Discrete material optimization of general composite shell structures. Int J Numer Methods Eng 62(14):2009–2027

Svanberg K (2002) A class of globally convergent optimization methods based on conservative convex separable approximations. SIAM J Optim 12(2):555–573

Terada K, Kikuchi N (2001) A class of general algorithms for multi-scale analyses of heterogeneous media. Comput Methods Appl Mech Eng 190(40–41):5427–5464

Theocaris PS, Stavroulakis GE (1999) Optimal material design in composites: an iterative approach based on homogenized cells. Comput Methods Appl Mech Eng 169(1–2):31–42

Wang F, Lazarov BS, Sigmund O (2011) On projection methods, convergence and robust formulations in topology optimization. Struct Multidiscip Optim 43(6):767–784

Xu SL, Cai YW, Cheng GD (2010) Volume preserving nonlinear density filter based on heaviside functions. Struct Multidiscip Optim 41(4):495–505

Yan X, Huang X, Sun G, Xie YM (2015) Two-scale optimal design of structures with thermal insulation materials. Compos Struct 120:358–365

Yin X, Lee S, Chen W, Liu WK, Horstemeyer MF (2009) Efficient random field uncertainty propagation in design using Multiscale analysis. ASME J Mech Des 131(2):021006 (021010 pages)

Zhao J, Wang C (2014a) Robust structural topology optimization under random field loading uncertainty. Struct Multidiscip Optim 50(3):517–522

Zhao J, Wang C (2014b) Robust topology optimization under loading uncertainty based on linear elastic theory and orthogonal diagonalization of symmetric matrices. Comput Methods Appl Mech Eng 273:204–218

Acknowledgements

Grant support from NIST 70NANB14H012 under Advanced Materials Center for Excellence: Center for Hierarchical Materials Design (CHiMaD) is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A - Improved Sensitivity Analysis for Volume Preserving Filter

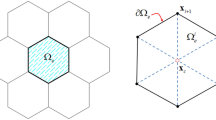

In this section, we will derive improved sensitivity for topology optimization using volume preserving filtering (Xu et al. 2010). Assuming the design domain is meshed into N finite elements and given pseudo density (design variables) ρ i of the ith element (i ∈ {1, 2, ... , N}), after linear density filtering, we obtain density \( {\overline{\rho}}_e \) for the eth element as,

where v i represents the volume of the ith element. w i is the weighting coefficient given by

where x i is the center location vector of element i and r is the filter radius. Ψ e in (52) denotes the neighborhood of element e, which is specified by the elements whose centers are located within r of element e, i.e.

Then, \( {\overline{\rho}}_e \) is filtered by the volume preserving nonlinear density filter and the filtered/physical density is

where β is the smooth parameter in the Heaviside function. η is the volume preserving parameter to ensure the volume is the same before and after nonlinear filtering in (55). η is determined by method of bisection meeting the following volume preserving condition,

By virtue of the chain rule, the sensitivities of a general performance function f with respect to the design variable ρ i is obtained as follows in the literature (Xu et al. 2010),

where \( \partial {\tilde{\rho}}_e/\partial {\overline{\rho}}_e \) and \( \partial {\overline{\rho}}_e/\partial {\rho}_i \) should be deduced from (55) and (52).

We discovered that the numerical sensitivities obtained using (57) usually have some discrepancy with the sensitivities obtained using the finite difference method. To remove this discrepancy, the improved analytical sensitivity analysis should be stated as,

where ∂η/∂ρ i can be obtained by taking the derivative of the volume preserving condition dg/dρ i = 0 as

Finally for a general performance function f, its sensitivity can be sated as,

which is different from (57).

Appendix B - PCG with Rounding-off Error Correction

For a linear system Ax = kwith A symmetric and positive definite, the following formulas are used in conjugate gradient method:

where x 0 is an arbitrary starting point.

With the correction to remove rounding-off error, the above routine is refined by the following formulas:

The above is for conjugate gradient method. For preconditioned conjugate gradient method in OOFEM, similar corrections can be incorporated as well.

Rights and permissions

About this article

Cite this article

Deng, J., Chen, W. Concurrent topology optimization of multiscale structures with multiple porous materials under random field loading uncertainty. Struct Multidisc Optim 56, 1–19 (2017). https://doi.org/10.1007/s00158-017-1689-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-017-1689-1