Abstract

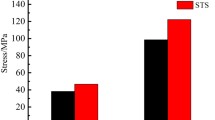

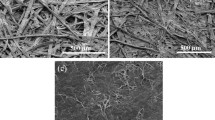

Wetlaid/spunlace (wetlace) materials consisting of wood pulp and short-cut fibers are leading the way in the development of dispersible moist wipes due to their wet strength during use and disintegration under flow field. However, short-cut fibers are still not well understood in terms of reasonable balance between material wet strength and dispersibility. In this study, wetlace materials were prepared via four types of water-jet pressure sums, and the effects of four types of short-cut fibers (Lyocell, Danufil, Viloft and hydrophilic polyester) on the wet strength and dispersibility of wetlace materials were investigated for the first time. The results suggest that at a water-jet pressure sum of around 190 bars, wood pulp/Lyocell wetlace material reaches the dispersion threshold, but wood pulp/hydrophilic polyester material has lost dispersibility, and the former wet strength is much higher than the latter. However, the required water-jet pressure sum at the dispersion threshold of wood pulp/Danufil or wood pulp/Viloft wetlace materials are more than 200 bars, and the corresponding wet strength is close to that of wood pulp/Lyocell wetlace material. Overall, Lyocell entanglements as reinforcement of wetlace material can achieve sufficient wet strength and excellent dispersibilty with low water-jet pressure sum, providing guidelines for the production of excellent pulp-based moist wipes.

Similar content being viewed by others

References

Al-Johany SS, Alqahtani AS, Alqahtani FY, Alzahrani AH (2011) Evaluation of different esthetic smile criteria. Int J Prosthodont 24(1):64–70

Amiot M, Lewandowski M, Leite P, Thomas M, Perwuelz A (2014) An evaluation of fiber orientation and organization in nonwoven fabrics by tensile, air permeability and compression measurements. J Mater sci 49:52–61

Annis VR, McDade MA(2010) Disposable nonwoven wiping fabric and method of production. Patent 7732357B2, US

Bernt I (2011) Fine-tuning of paper characteristics by incorporation of viscose fibres. Lenzinger Berichte 2011:78–85

EN ISO 9073-3:1989 Textiles-test methods for nonwovens-part 3: determination of tensile strength and elongation

Fischer G, Li VC (2007) Effect of fiber reinforcement on the response of structural members. Eng Fract Mech 74:258–272

Grishanov S, Tausif M, Russell SJ (2012) Characterisation of fibre entanglement in nonwoven fabrics based on knot theory. Compos Sci Technol 72:1331–1337

Hong W, Xiangyu J, Ningtao M, Russell SJ (2010) Differences in the tensile properties and failure mechanism of PP/PE core/sheath bicomponent and PP spunbond fabrics in uniaxial conditions. Tex Res J 80:1759–1767

Hubbe MA, Koukoulas AA (2016) Wet-laid nonwovens manufacture—chemical approaches using synthetic and cellulosic fibers. Bioresources 11:5500–5552

Industrial Fabrics Association International (2014) Trützschler and Voith awarded quality certificate. https://advancedtextilessource.com/2014/01/11/trutzschler- and-voith-awarded-quality- certificate/. Accessed 12 May 2018

Latifi M, Tafreshi HV, Pourdeyhimi B (2008) A note on an optical method to evaluate fiber dispersion in wet-laid nonwoven process. Text Res J 78:518–523

Manning JH, Miller JH, Quantrille TE(1988) Hydroentangled disintegratable fabric. Patent 4755421, US

Mao N, Russell S (2005) Structure-process-property relationships of hydroentangled fabrics. Lenzinger Berichte 84:50–61

Mao N, Russell SJ (2006) A framework for determining the bonding intensity in hydroentangled nonwoven fabrics. Compos Sci Technol 66:80–91

Migneault S, Koubaa A, Erchiqui F, Chaala A, Englund K, Wolcott MP (2011) Application of micromechanical models to tensile properties of wood–plastic composites. Wood Sci Technol 45(3):521–532

Olivo T (2016) Personal care wipes: a growing market. http://www.nonwovens-industry.com/issues/2016-02-01/viewfeatures/personal-care-wipes-a-growing-market/. Accessed 12 May 2018

Philip M (2004) Flushable wipes-past, present and future. Nonwovens Industry. http://www.thefreelibrary.com/Flushable+wipes--past%2c+present+and+future.-a0126490873. Accessed 12 May 2018

Rawal A, Moyo D, Soukupova V, Anandjiwala R (2007) Optimization of parameters in hydroentanglement process. J Ind Text 36:207–220

Roggenstein W (2011) Viscose fibres with new functional qualities. Lenzinger Berichte 89:72–77

Russell SJ (2006) Handbook of nonwovens. Woodhead Publishing, UK

Sawhney APS, Condon B, Reynolds M, Slopek R, Hui D (2010) Advent of greige cotton non-wovens made using a hydro-entanglement process. Text Res J 80:1540–1549

Seyam A, Shiffler D, Zheng H (2005) An examination of the hydroentangling process variables. Int Nonwoven J 14:25–33

Strandqvist MS (2012) Flushable moist wipe or hygiene tissue. Patent 0199301A1, US

Suragani Venu LB, Shim E, Anantharamaiah N, Pourdeyhimi B (2014) Impacts of high-speed waterjets on web structures. J Text I 105:430–443

Viazmensky H, Benjamin ER (1994) Wet wipe. Patent 5292581, US

Viazmensky H, Richard CE, Williamson JE (1991) Water entanglement process and product. Patent 5009747, US

Wang H, Pang LS, Jin XY, Yin BP, Wu HB (2010) The influences of hydrophilic finishing of PET fibers on the properties of hydroentangled nonwoven fabrics. J Eng Fiber Fabr 5:26–32

Xiang P, Kuznetsov AV (2008) Simulation of shape dynamics of a long flexible fiber in a turbulent flow in the hydroentanglement process. Int Commun Heat Mass 35:529–534

Xiang P, Kuznetsov AV, Seyam AM (2006) Modeling of the hydroentanglement process. J Eng Fiber Fabr 1(2):1–15

Yan HW, Norman B, Lindstrom T, Ankerfors M (2006) Fibre length effect on fibre suspension flocculation and sheet formation. Nor Pulp Pap Res J 21:30–35

Yu W (2006) Textile samples. China Textile Press, Beijing

Yu W, Chu C (2002) Textile physics. Donghua University Press, Shanghai

Zhang Y, Jin X (2018) The influence of pressure sum, fiber blend ratio, and basis weight on wet strength and dispersibility of wood pulp/Lyocell wetlaid/spunlace nonwovens. J Wood Sci. https://doi.org/10.1007/s10086-018-1699-7

Zhang Y, Zhao Y, Latifi M, Wang R, Jin X (2017) Investigation of the mechanical and dispersible properties of wood pulp/Danufil wetlaid nonwovens with/without hydroentanglement. J Text I. https://doi.org/10.1080/00405000.2017.1362747

Zhang Y, Deng C, Wang Y, Huang C, Zhao Y, Jin X (2018) A new dispersible moist wipe from wetlaid/spunlace nonwoven: development and characterization. J Ind Text. https://doi.org/10.1177/1528083718757524

Zwick KJ, Vogel NJ, Baker JK (2013) Dispersible moist wipe. Patent 063737AI, WO

Zwick KJ, Vogel NJ, Lee W, Baker JK, Ackroyd C (2015) Dispersible hydroentangled basesheet with triggerable binder. Patent 0216374AI, US

Acknowledgements

The authors wish to express their sincere gratitude to Zhejiang Hezhong Nonwoven Co., Ltd for their support in providing the means for conducting experiments. This work was supported by the Shaoxing University Scientific Research Staring Foundation [grant number 20185026] and the Fundamental Research Funds for the Central Universities [grant number CUSF-DH-D-2016017].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Xu, Y., Zhao, Y. et al. Effects of short-cut fiber type and water-jet pressure sum on wet strength and dispersibility of wood pulp-based wetlaid/spunlace wipes. Eur. J. Wood Prod. 77, 33–43 (2019). https://doi.org/10.1007/s00107-018-1369-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1369-x