Abstract

Three Closed Transfer Systems (CTS) were evaluated for their reduction of operator exposure to plant protection products during mixing and loading: the inverted extraction systems, easyFlow M and easyconnect, and the probe extraction system, GoatThroat®. Exposure data were generated for gloves, hands, head, inner and outer body dosimeters generated in 4 European countries for high rate (Sorbitol) and low rate (Xylitol) surrogate products used by 12 operators. Exposure values were compared with predicted data using the Agricultural Operator Exposure Model as a benchmark for open pour loading (used in the EFSA Guidance). The CTS types conformed with the ISO 21191 standard for CTS performance, and their potential to significantly reduce operator exposure was confirmed in this study. There was no statistical difference in potential (naked) or actual (one layer of clothing) operator exposure using both inverted CTS types; allowing these data to be pooled. The inverted CTS types resulted in higher mean protection (> 98% potential exposure and > 95% actual exposure) than GoatThroat® (> 80% potential exposure and > 95% actual exposure). These data can be used to derive reduction factors that could be used in the AOEM model for calculations involving mitigation e.g., 0.05 for inverted CTS since they reduced exposure by > 95% and 0.3 for probe extraction CTS types. All 3 CTS significantly reduced operator exposure to products during M&L. These and future CTS types which comply with ISO 21191 standards could be considered as mitigation devices. These findings will help to build confidence of farmers to use CTS routinely, resulting in safer pesticide handling.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Plant protection products (PPPs) are applied to crops while ensuring an accurate dose is applied with minimal exposure of the active substance to the operator. The authorization process for PPPs ensures that only safe and effective PPPs are introduced or remain on the market. Such non-dietary risk assessments ensure that exposure remains below the toxicological threshold known as the Acceptable Operator Exposure Level (AOEL). The Agricultural Operator Exposure Model (AOEM) is used in Tier 1 of a safety assessment to estimate operator exposure, which is compared to AOEL, derived from regulatory animal tests. When exposure estimates from models, e.g., the AOEM, are below the AOEL, the risk is considered acceptable from a regulatory standpoint. The AOEM is currently used in the EU to estimate operator exposure for European registration processes of PPPs (EFSA et al. 2022).

It has been reported for ground boom spray application that ~ 90% of the total chemical exposure is due to the operator handling the PPP during mixing and loading (M&L) of the spray mixture, while the applicator (sitting in a closed cabin) receives the remaining 10% during spraying (Hofman 1994; Großkopf et al. 2013; CLE et al. 2023). Importantly, contamination of the user should be kept as low as possible and one way to achieve this is to use coveralls combined with personal protective equipment, which can reduce exposure by > 95% (MacFarlane et al. 2013; Thouvenin et al. 2017). An emerging technology designed to minimize further exposure of operators to PPPs during M&L of the spray tank is the use of CTS. These devices allow liquid pesticide mixtures to be transferred from their container to the spray tank without splashing or spilling of the PPP, to reduce exposure of the operator and the environment. By contrast, open pour practices may leave the operator and the environment open to significant exposure due to spillage. There are only a few field studies which report the exposure to operators using CTS during M&L of PPPs. Due to the lack of appropriate data to demonstrate the safety of CTS in the field, the European Food Safety Authority (EFSA) and other regulators hesitate to accept these risk mitigation measures in a regulatory context and the efficacy of these systems in terms of operator safety (EFSA et al. 2022). To address this, an operator exposure study was conducted to determine the reduction of operator exposure with 3 types of CTS during M&L under realistic field conditions. The systems were easyFlow M, easyconnect and GoatThroat®. EasyFlow and easyconnect are inverted extraction systems (i.e., the bottle is turned upside down) with mechanical rinsing for cleaning (Fig. 1). The main difference between easyFlow and easyconnect is how the container is connected to the CTS. EasyFlow uses an adapter that is screwed on the PPP container to replace the original cap, which means the PPP container must have an additional foil seal to avoid contact with the product during removal of the cap. Easyconnect is a system where the PPP containers are pre-fitted with a special cap and do not need an additional foil seal. Both systems were specifically designed to mitigate exposure during the filling process of liquid products into large tanks. GoatThroat® is a probe extraction system with manual rinsing for cleaning (shaking), for which the PPP containers must have a foil seal. This CTS type was designed for smaller rigs but was included in this study to cover the variability of the use of different CTS. The use of different types of CTS covered a common variability used on farms, which increases the scientific validity of the study.

Currently, the only international standard available for CTS is the ISO 21191:2021-02 (ISO 2021), which specifies the operator and environment-related safety requirements and their verification for the design and manufacture of CTS for liquid formulations of PPPs. Importantly, it was designed to also cover future CTS developments and machineries (all three CTS types evaluated in this study were tested to ISO 21191 standards) (ISO 2021). This ISO standard lists 3 parameters with direct relevance to the operator: (1) no leakage during transfer and rinsing; (2) maximum residue on coupling after disconnection should be < 0.25 mL of undiluted product and (3) the maximum residue in any container rinsed shall not exceed 0.01% of the original content of the container. CTS types passing these tests have the potential to significantly reduce the operator exposure. However, there are only a few field studies published regarding the exposure to operators during M&L of PPPs (Knaak et al. 1980; Wild et al. 2000; Aprea et al. 2016) and no reports proving that the potential of CTS to reduce operator exposure under realistic field conditions. Therefore, this study was conducted in 4 countries to evaluate the general efficiency of CTS to reduce exposure during M&L. This was calculated by comparing the operator exposure values using CTS with existing data from the AOEM as a benchmark for open pour loading (BfR 2013; Großkopf et al. 2013). These data were also used to derive reduction factors for calculating the exposure to PPPs during M&L when using CTS as part of a risk assessment. A CTS type that would reduce the exposure by at least 90% compared with open-pour data from the AOEM model, would allow a recommendation to apply a universal reduction factor as a risk mitigation measure when using a CTS. CTS types that fulfil the ISO standard could then use the same reduction factor.

2 Material and methods

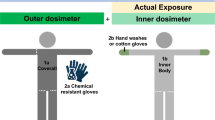

Details of study design and analytical methods are described in Online Resource 1 (Supplementary Material), and a summary of the main parameters are shown in Table 1. The study generated samples of gloves, hands, head, inner and outer body dosimeters in 4 countries (Germany, the Netherlands, Spain, and France), which were all analysed in a single laboratory, for 3 CTS types and 2 products, each tested on consecutive days by 12 operators. The products were Sorbitol, which represents a higher active substance concentration product with a higher use rate (4.6 kg a.s./ha), and Xylitol, which represents a lower active substance concentration product with a lower use rate (0.053 kg a.s./ha). These rates were chosen since they correlate with the rates used in the studies upon which the AOEM was developed. Each operator handled 3 Xylitol containers and 25 Sorbitol containers; therefore, the effect of the volume handled was accounted for. The study monitored the M&L for two theoretical spray tank volumes (1000 L and 5000 L), which represent the lower and upper range of spray tank volumes in regular commercial use. The number of M&L activities was based on an application to 50 ha, which is representative of a typical working day. Dermal exposure to the test item was measured by the operators wearing two layers of whole-body dosimeters to determine potential (naked) and actual (one layer of clothing and protective gloves) exposure.

Each CTS type was pre-tested to a subset of the ISO 21191 standard (non-GLP) and the actual operator exposure study was conducted according to GLP. The study focussed on exposure to liquids; inhalation exposure was not measured since respiratory exposure to a pesticide in liquid form is reported to be generally more than one order of magnitude lower than exposure to a pesticide in granular form (Knaak et al. 1980; Aprea et al. 2016). The study by Aprea et al. (2016) also showed that the dermal route was the major route of exposure.

3 Results

3.1 Predicted exposure without CTS using AOEM

The predicted operator exposure to Sorbitol and Xylitol used in outdoor open pour applications was calculated using the AOEM (Table 2 and Online Resource 2, Table S1, Supplementary Material). The 75th (chronic) and 95th (acute) centile values for potential and actual exposures for high and low application rates predicted by the AOEM were used to evaluate the reduction in exposure using the 3 CTS types.

3.2 Potential exposure reduction using 3 CTS types

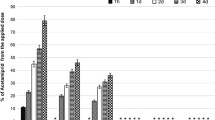

The potential exposure to Sorbitol and Xylitol using the CTS types is shown in Fig. 2 (the range, mean, 75th and 95th centiles are detailed in Online Resource 2, Table S2 and individual values for all samples are shown in Online Resource 2, Table S3, Supplementary Material). The mean values of Sorbitol for easyconnect (13.1 mg/person) and easyFlow (7.1 mg/person) were not statistically significantly different from each other and could thus be pooled to represent “inverted CTS” types. The same is true for the exposure to Xylitol, with mean values for easyconnect (0.27 mg/person) and easyFlow (0.29 mg/person) not statistically different from each other (p > 0.05). By contrast, the potential exposures to Sorbitol and Xylitol using the GoatThroat® CTS were statistically significantly higher (101.3 and 4.36 mg/person, respectively) than the inverted CTS results (p < 0.01). For this reason, these data were handled separately in the calculations for exposure reduction.

Potential exposure to a Sorbitol and b Xylitol measured on operators using easyconnect (green bars), easyFlow (blue bars); GoatThroat® (orange) CTS. Individual values are shown, together with the median, highest and lowest values (error bars, without outliers), 25th and 75th centiles, n.s. no statistical difference; **statistical difference p < 0.01, according to a student’s t test

Figure 3 shows individual operator values for the potential exposure to Sorbitol and Xylitol. The 75th and 95th centiles for Sorbitol using the inverted CTS types include the extremely high value measured for Operator 32 (using easyconnect, green bars) who unintentionally unscrewed the connector on the container (Fig. 3a). Despite this high value, it is still below 10% of the 95th centile of the AOEM. All other values for the inverted CTS type were below 10% of the AOEM 75th centile.

Individual operator values for the potential exposure to a Sorbitol and b Xylitol. Green bars denote easyconnect, blue bars denote easyFlow and orange bars denote GoatThroat®. The red line denotes 10% of the open-pour AOEM 95th centile and the purple line denotes 10% of the open-pour AOEM 75th centile

The handled amount of product containing Xylitol by each operator was much lower than for Sorbitol (2.65 kg Xylitol/day compared to 230 kg Sorbitol/day, respectively). Therefore, all values for potential (and actual) exposure of Xylitol are much lower than for Sorbitol (Fig. 3b). Operator 32 again exhibited a markedly high outlier exposure for Xylitol, which was also the highest measured exposure value for the inverted CTS types. Despite this, all values for actual exposure using the inverted CTS type were below 10% of the AOEM 75th centile.

3.3 Actual exposure reduction by using three CTS types

There was no statistically significant difference in the actual exposure when using the CTS types (Online Resource 2, Tables S2 and S3, Supplementary Material). Indeed, the actual exposure to Sorbitol and Xylitol appeared to be random across the different operators using all 3 CTS types (Fig. 4), with no correlation of the amount on face wipes, hand washes and inner dosimeters with the measured values on the gloves and outer dosimeters. All actual exposure values for Sorbitol (ranging between 0.021 and 0.83 mg/person) were well below the value of 10% of the 75th centile of the AOEM. The Xylitol values ranged between 0.019 and 0.11 mg/person and were below the value of 10% of the 95th centile of the AOEM. However, more than half of the replicates, irrespective of the device used, exceeded 10% of the 75th centile of the exposure calculated with the AOEM.

3.4 Exposure reduction using CTS

All 3 CTS resulted in a marked reduction of the potential operator exposure compared to the AOEM value (Fig. 5). The % reduction values for each operator using inverted CTS types for Sorbitol and Xylitol were all > 90% for the 75th and 95th centiles, with the single exception of the 75th centile for Sorbitol for Operator 32 using easyconnect (Fig. 5a), for which the reduction was 77% caused by the accidentally higher exposure due to the incorrect use of the cap. Despite this, the overall median % reduction of potential exposure by the inverted CTS devices was 98.7% (Table 3). While the % reduction values using GoatThroat® for the 95th centile for Sorbitol and Xylitol were mostly above 90% (Fig. 5b and d), most of the values for the 75th centile were below 90% (Fig. 5a and c), resulting in an overall median % reduction of potential exposure of 82.0% (Table 3).

All CTS forms also markedly reduced actual exposure to Sorbitol and Xylitol (Fig. 6). For the high application rate substance, Sorbitol, the % reduction values for the 75% and 95th centiles by all 3 CTS forms were almost 100% (Fig. 6a and b; Table 3). This was also observed for Xylitol for the 95% centile (Fig. 6C); however, the values of the % reduction for the 75th centile for Xylitol were lower for both GoatThroat® (83.8%) and inverted CTS (85.3%) (Fig. 6c and Table 2). Despite this, the overall median % reduction of potential exposure by inverted CTS types and GoatThroat® were above 94% (Table 3).

4 Discussion

4.1 Choice of test substances

An unexpected finding was that the actual exposures (i.e., the sum of the amount in the inner dosimeter, face wipes and hand wash samples) to Sorbitol and Xylitol did not correlate with the amounts measured on the gloves and outer dosimeters. The values were more reflective of a random spread of amounts present on operators, independent of the CTS type. In theory, neither the hands nor the inner dosimeters should be exposed to the test substances because both are protected by nitrile gloves or the outer dosimeters. However, significant amounts of up to 0.63 µg of Sorbitol and 38 µg Xylitol were detected in the hand washes and up to 0.19 mg of Sorbitol and 0.061 mg Xylitol were detected on the inner dosimeters. The reason for random values could be due to the fact that Sorbitol and Xylitol are very common sweeteners and the use of these by the operators may have resulted in variable background levels. This may have interfered with the accurate measurement of residues generated during the study, resulting in an overestimation of the amounts measured for the hand washes and inner dosimeters. Indeed, in all cases, the residues measured on the protected hands and the inner dosimeters were higher than the unprotected head and neck (the measurements of which ranged between 0.22 and 6.4 µg/person), indicating a certain background level contamination—especially with the inner dosimeters. The higher background is more conservative in a regulatory context since these result in a higher apparent exposure and lower value for the reduction factor.

The 2 test substances have several advantages, including a good water solubility, making them easy to use in the test liquid formulations. The substances can be used to modulate the viscosity without the use of additives. Since they are food grade, there are no operator exposure concerns and there are fewer problems regarding their disposal at the end of the study. In addition to the disadvantage observed in the current study of both substances exhibiting background contaminations due to their ubiquitous use, they can also be impacted by microbiological degradation when they are in solution and have relatively limited analytical sensitivities compared to other substances. While this study provides the first results of the difference in exposure due to the type of CTS used, future studies could be conducted using actual PPPs with minimal background levels to extend the number of products tested and, potentially, lead to a higher calculated reduction in exposure due to the lower background levels of these products.

4.2 Recovery rates

For the field recovery and travel fortification samples, the spiked amounts included several concentrations which were purposefully very low (e.g., 0.01 and 0.1 µg or µg/L) to ensure that they covered the expected (but at the time unknown) low exposures. However, the background levels of Sorbitol and Xylitol relative to the fortification level significantly interfered with the recovery, therefore, the results for these amounts were unusable. This did not impact the study results because these fortification levels were generally not relevant for the correction of the operator samples. Higher fortification levels generally reflected the residues detected in the operator samples and were thus considered valid (they confirmed the stability of Sorbitol and Xylitol under the environmental conditions during monitoring and during shipment and storage prior to analysis).

4.3 Exclusion of operator 1

Operator 1 was excluded from the data evaluation, despite there being no reason to do this from a statistical point of view. This operator used a different probe i.e., a telescope probe. The other operators using GoatThroat® used a standard dip tube. A telescope probe has a tube within another, so that the product can be caught between the 2 tubes, making it difficult to rinse the PPP effectively. As a follow up to this, a reduced ISO evaluation of the 3 CTS types was conducted in which samples were taken from the standard tube as well as the overlapping part of the telescopic tube after rinsing the container. This revealed that that the rinsing water did not reach the overlapping areas of the telescopic tube, which are only accessible after the telescopic tube was extended again (Online Resource 3, Fig. S1, Supplementary Material)). Therefore, the GoatThroat® system with the telescopic tube does not pass the ISO certification (test 5.2.2) (ISO 2021) due to excessive residues on the tube (> 100-fold higher than the standard tube), whereas the standard tubes pass this test. While the use of the telescopic tube by Operator 1 did not result in a markedly higher exposure to Sorbitol (Fig. 3a), this operator did have the highest residue measured for Xylitol (Fig. 3b). This could be explained by the marked difference in viscosity of both test items. The sorbitol solution with very low viscosity (15 mPas) could be rinsed out between the 2 overlapping tubes, while the highly viscous (470 mPas) xylitol solution would be very difficult to remove.

4.4 Potential outliers due to operator error

There was one outlier in the easyconnect dataset. This was due to the operator unintentionally loosening the cap instead of tightening it. This operator error occurred only once during the study and was quickly detected. This operator error can potentially occur with all systems that require rotation of the container along the vertical axis during rinsing. As a result, subsequent training sessions of both systems that require this operation (easyconnect and easyFlow) included advice regarding the unintended unscrewing of the adapter. By increasing the routine of the operators, this user error disappeared. Despite this incident with one operator, the 75th and 95th centile values still resulted in an exposure reduction of > 95%. Additionally, there are mechanical mitigation measures that are being implemented both on the container as well as on the machine side, e.g., a higher resistance against unintended unscrewing of the container (higher closing torque as well as an increased resistance of the tamper evidence band). Systems are in development that do not require rotation during rinsing, effectively eliminating this risk of unintentionally unscrewing the container.

Cleaning of the containers with GoatThroat® system was performed manually (shaking). The fatigue factor of the operator when manually rinsing 27 containers is important and probably led to reduced diligence by the operators to properly clean the equipment generating more contamination than is expected when the directions are properly followed. There was also one incident in which the spray tank overflowed during the rinsing of a container with Sorbitol by Operator 15 using easyconnect. The operator immediately stopped his activities and moved away from the affected area. During the overflow, there were no obvious splashes reaching the operator and the spillage was cleaned away by another person. The results indicated that this did not result in increased exposure to Operator 15.

4.5 Exposure reduction

The study showed that, for the inverted CTS types, there was an exposure reduction of > 95% for low and high loading rates for the 75th and 95th centiles (Table 3). Based on this, a reduction factor of up to 0.05 can be applied as a risk mitigation measure when using an inverted CTS.

The potential and actual exposure to Sorbitol and Xylitol were < 10% of the 95th centile of the exposure calculated with the AOEM. Sorbitol exposure was also < 10% of the AOEM 75th centile; however, more than half of the replicates for Xylitol, irrespective of the device used, exceeded 10% of the 75th centile. This observation could be expected since all residue values for this compound are low and thus impacted by the relatively high background levels of this compound. In all cases, the residues measured on protected hands and the inner dosimeters were higher than those on the unprotected head and neck, indicating there was background contamination especially relating to the inner dosimeters. In addition, the values for the actual exposure (face wipes, + hand washes + inner dosimeters) are not correlated to the exposure of the outer dosimeters. Therefore, values for the actual exposure for Xylitol cannot be used to determine the reduction of its exposure by different CTS types.

The GoatThroat® CTS achieved a significant exposure reduction of > 70% with respect to the 75th centile for the low and high-rate product compared to open pouring. Based on this, a reduction factor of up to 0.3 can be applied as a risk mitigation measure when using a probe extraction CTS. However, the exposure reduction for the 95th centile was higher, with > 85% for the high rate and > 90% for the low-rate product. Despite not achieving the 90% goal, the levels of reduction measured here are higher than those reported by others. For example, the US EPA published results for probe systems tested in the US that revealed higher exposures for the CTS than for open pour exposures (US EPA 2020). Notably, the US EPA study was not comparable with ours in terms of rinsing, with 28 out of 38 systems used being returnable systems, which are often not rinsed at all. None of the systems evaluated in the US EPA study were tested for the ISO 21191 compliance; indeed, 10 systems were not completely closed and only 2 systems evaluated were non-returnable completely closed systems. Therefore, only < 5% of the US EPA data set could be compared directly with the scenario covered in this study.

There are several reasons for the lower exposure reduction exhibited by the GoatThroat compared to that of the inverted CTS. GoatThroat® was designed to fill smaller spray rigs with fewer loadings per day than easyconnect and easyFlow which were specifically designed for transfer of large amounts of PPPs. This introduces a fatigue factor of the operator when manually rinsing 27 containers, which could well lead to reduced diligence by the operators to properly clean the equipment, thus generating more contamination than expected than when the directions are followed properly. This hypothesis is strengthened by the results of the ISO testing in which the measured residues which could potentially lead to an exposure to the PPP were very low with only 2–3 loadings.

The container size for the low-rate substance, Xylitol, was 5 L and for the high-rate substance, Sorbitol, it was 10 L (the latter representing the worst-case scenario). This meant that for each operator only 3 Xylitol containers were needed compared to 25 Sorbitol containers. Despite the difference in the number of canisters, there was no difference in the extent of protection between the substances. Therefore, even when using larger tanks and multiple loadings per day, the ISO tests were confirmed. There were also no apparent differences for the loading of small sprayers (for which more partial dosing is required – considered to a worst case) and large sprayers. Likewise, there was no difference in the operator exposure between the countries in which the study was performed.

5 Conclusions

The key objective of this project was to increase the regulatory acceptance of CTS by measuring operator exposure during the use of CTS under realistic field scenarios and providing data for quantitative risk assessment. Except for GoatThroat® using the telescope dip pipe, the CTS tested complied with the ISO standards in field trials with larger tanks and multiple loadings per day. A combination of gloves and any of the 3 CTS results in a similar reduction of exposure that almost completely prevents actual exposure to PPPs during M&L. Therefore, when calculating exposure using the AOEM, reduction factors of up to 0.05 and 0.3 can be applied as a risk mitigation measure when using an inverted and probe extraction CTS type, respectively. This study will also represent future CTS solutions that comply with tests relevant for operator safety from the ISO 21191:2021. The long-term ambition is to make CTS technologies available to all European agriculture operators by 2030 and this study represents one step to achieve this goal.

References

Aprea MC, Bosi A, Manara M et al (2016) Assessment of exposure to pesticides during mixing/loading and spraying of tomatoes in the open field. J Occup Environ Hyg 13:476–489. https://doi.org/10.1080/15459624.2016.1143948

BfR (2013) Bundesinstitut für Risikobewertung. Joint development of a new Agricultural Operator Exposure Model. Project report. Retrieved from [website]: https://www.bfr.bund.de/cm/350/joint-development-of-a-new-agricultural-operator-exposure-model.pdf. Accessed March 15 2023

Kuster C, Durand-Reville J, Kluxen F et al. (2023) CropLife Europe. Questions and answers concerning the topic: Personal protective equipment in European pesticide risk assessment - an industry perspective. Retrieved from [website]: https://croplifeeurope.eu/wp-content/uploads/2023/03/CropLife_QA_FEB_0445.pdf. Accessed March 15 2023

EFSA, Charistou A, Coja T et al (2022) European Food Safety. Authority Guidance on the assessment of exposure of operators, workers, residents and bystanders in risk assessment of plant protection products. EFSA J 20:e07032. https://doi.org/10.2903/j.efsa.2022.7032

Großkopf C, Mielke H, Westphal D et al (2013) A new model for the prediction of agricultural operator exposure during professional application of plant protection products in outdoor crops. J Verbrauch Lebensm 8:143–153. https://doi.org/10.1007/s00003-013-0836-x

Hofman V (1994) Closed transfer systems. Book Closed transfer systems, city

ISO (2021) ISO 21191:2021 Equipment for crop protection—Closed transfer systems (CTS)—Performance specification. Retrieved from [website]: https://www.iso.org/standard/70063.html. Accessed March 15 2023

Knaak JB, Jackson T, Fredrickson AS et al (1980) Safety effectiveness of closed-transfer, mixing-loading, and application equipment in preventing exposure to pesticides. Arch Environ Contam Toxicol 9:231–245. https://doi.org/10.1007/bf01055377

MacFarlane E, Carey R, Keegel T et al (2013) Dermal exposure associated with occupational end use of pesticides and the role of protective measures. Saf Health Work 4:136–141. https://doi.org/10.1016/j.shaw.2013.07.004

Thouvenin I, Bouneb F, Mercier T (2017) Operator dermal exposure and protection provided by personal protective equipment and working coveralls during mixing/loading, application and sprayer cleaning in vineyards. Int J Occup Saf Ergon 23:229–239. https://doi.org/10.1080/10803548.2016.1195130

US EPA (2020) Review of agricultural handler exposure task force (AHETF) monograph: “mechanical transfer of liquids” (AHE1022). Retrieved from [website]: https://www.epa.gov/sites/default/files/2020-01/documents/epa_review_ahe1022_monograph_d454706.pdf. Accessed March 15 2023

Wild SA, Mathers JJ, Glass CR (2000) The potential for operator hand contamination to pesticides during the mixing and loading procedure. Asp Appl Biol 57:179–183

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors. The research was conducted as scientific expert contribution of the authors to the above-mentioned industry association CropLife Europe teams. The editorial work on the manuscript (Nicola Hewitt) was partly sponsored by CropLife Europe.

Author information

Authors and Affiliations

Contributions

JS, CJK, UB, FS, TO, JPH, SA, NM, KV, and MK made substantial contributions to the conception and design of the study, as well as the analysis and interpretation of data. JS, CJK and NJH drafted the manuscript. All authors revised and approved the version for publication.

Corresponding author

Ethics declarations

Conflict of interest

J. Sasturain, U. Blaschke, F. Stauber, T. Oteyza, JP. Huby, S. Adham, N. Morgan, K. Vinck, CJ. Kuster all work for different companies within the agrochemical industry. T. Oteyza is the chair of CTS working group of CropLife Europe, Brussels, Belgium. M. Kicinski works for CropLife Europe, the European agrochemical industry association (former ECPA). J. Sasturain, C.J. Kuster, U. Blaschke, F. Stauber, T. Oteyza, J.P. Huby, S. Adham, N. Morgan, K. Vinck and M. Kicinski are members of CropLife Europe. N.J. Hewitt is a scientific consultant. Funding for this project was provided by CropLife Europe. The authors declare no other conflict of interest relating to the material presented in this article. The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sasturain, J., Blaschke, U., Stauber, F. et al. Minimizing operator exposure: field data analysis of three closed transfer systems for pesticide mixing and loading. J Consum Prot Food Saf 19, 143–153 (2024). https://doi.org/10.1007/s00003-023-01472-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00003-023-01472-7