Abstract

A new predictive model for the estimation of agricultural operator exposure has been developed on the basis of new exposure data to improve the current agricultural operator exposure and risk assessment in the EU. The new operator exposure model represents current application techniques and practices in EU Member States (MS) and is applicable for national or zonal authorisation of plant protection products as well as for approval of active substances in plant protection products (PPP) supporting a stepwise risk assessment. 34 unpublished exposure studies conducted between 1994 and 2009 were evaluated for the new model. To ensure a very high quality of data the studies had to meet a set of quality criteria, e.g. GLP conformity or compliance with OECD guidance. Exposure data and supplementary information on the trials were used for a statistical analysis of exposure factors. The statistical analyses resulted in six validated models for typical outdoor scenarios of pesticide mixing/loading and application. As a major factor contributing to the exposure of operators, the amount of active substance used per day was identified. Other parameters such as formulation type, droplet size, presence of a cabin or density of the canopy were selected as factors for sub-scenarios. For two scenarios the corresponding datasets were too small to identify reliable exposure factors; instead the relevant percentiles of the exposure distribution were used. The whole project report on the development of the new model (including the underlying study data) and the corresponding exposure calculators will be published at the BfR website (http://www.bfr.bund.de) after confirmation of the model by EU MS.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Several models have been used for more than 20 years to estimate the exposure of professional operators during application of plant protection products. Estimation of operator exposure is an integral part of the risk assessment during approval of plant protection products in Europe according to Regulation No 1107/2009, but despite several attempts no harmonised European model is available for the authorisation of PPP and approval of active substances in PPP so far. Currently, the Member States apply different approaches, e.g. the German Model (Lundehn et al. 1992) or the UK predictive operator exposure model (UK POEM; Hamey 1992), resulting in different estimates for the same exposure scenario. With the implementation of zonal registrations this practice has become questionable, as different exposure estimates are not compatible with a joint authorisation of plant protection products in European member states (MS). The existing models pose a further disadvantage: They are based on old data and do not reflect current application equipment and practices.

To overcome these problems, the BfR has initiated the establishment of a project team to develop a harmonised operator exposure model that is based on empirical data from up-to-date and scientifically valid exposure studies, i.e. studies were performed according to accepted criteria and are representative for relevant application systems. The focus was set on typical outdoor application scenarios, in particular on:

-

Low crop tractor/vehicle-mounted or trailed application (LCTM)

-

Low crop hand-held application (LCHH)

-

High crop tractor/vehicle-mounted or trailed application (HCTM)

-

High crop hand-held application (HCHH)

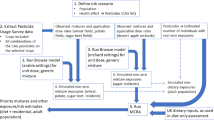

A comprehensive statistical approach was chosen for the analysis of the exposure data and the development of the model including the identification of exposure factors. The whole use process for plant protection products (PPP) was considered comprising the mixing/loading (ML) operations and the application (A) of the plant protection product including the cleaning and the maintenance of application equipment when considered part of the daily practice. The aim was to create a transparent, flexible and adjustable model for registration purposes that allows defined and stepwise consideration of risk mitigation measures (tiered approach).

2 Study selection and database

The European crop protection association (ECPA), its member companies as well as two further companies provided a collection of current exposure studies that had recently been used to support product authorisation in the EU. An expert group consisting of regulatory body representatives and industry representatives analysed the studies regarding their suitability for the model. To ensure a very high quality of data the studies that were accepted for inclusion in the model had to meet a set of quality criteria, which are listed below.

-

Full compliance with GLP (good laboratory practice)

-

Representative application methods and application techniques reflecting current agricultural application practices in Europe

-

Compliance with OECD guidance on the conduct of agricultural exposure studies (OECD 1997)Footnote 1

-

Monitoring of professional agricultural operators (e.g. farmers and contractors) working in accordance with GAP (good agricultural practice)

-

Data recording and observations according to current scientific knowledge

-

Consistent field recovery (any outlying data must be explainable on a scientific basis)

-

Suitable data form for model development (e.g. separately measured head, hand and body exposure)

-

Whole body dosimetry for dermal exposure (exclusion of patch data)

-

Inhalation exposure determined with appropriate personal air samplers

In total, 34 studies conducted in different European MS between 1994 and 2009 were accepted for evaluation (see Fig. 1 for a study overview). Most of the studies were designed to monitor exposure during a typical working day comprising the mixing and loading as well as the application of the PPP. In the cases where cleaning was performed it was usually not monitored separately but included in the application task. The equipment used comprised tractor/vehicle-mounted/-trailed or self-propelled sprayers as well as hand-held spray lances and knapsack (backpack) sprayers for application in low crops or high crops. Target area and total amount of active substance (sum of active substance applied per day) varied depending on the type of application and equipment used. The largest areas and highest amounts of active substance (a.s.) per day were observed for tractor/vehicle-mounted/-trailed application in low crops (Table 1).

Study overview; most of the operators were monitored in France, Spain or Germany and they treated grapevine or cereals; in the majority of the studies the operators used vehicle-mounted/vehicle-trailed spray equipment in low crops (LCTM) and high crops (HCTM); hand-held applications in low crops (LCHH) were performed with knapsack sprayers while spray lances (connected to a tank) were used for hand-held application in high crops (HCHH); different formulation types were applied, liquid formulations (EC emulsifiable concentrate, EW emulsion, oil in water; SC suspension concentrate, SL soluble concentrate) were the most commonly used ones, two studies were performed with powder formulations (WP wettable powder) and eight studies were performed with granular formulations (WG water soluble granules)

To create a database for the new model the exposure data were extracted from the studies and collected in a spreadsheet. In principle, each data record consisted of exposure values for inhalation, the head, the body and the hands. The potential dermal exposure of the body (excluding head and hands) was compiled from the measured residues on inner dosimeters (representing exposure of the skin below one layer of work clothing; actual exposure) and the measured residues on the outer dosimeters (normal work clothes). Potential hand exposure (unprotected hands) and actual hand exposure (protected hands) were determined from analysing (protective) outer gloves and hand washes/inner gloves. Various dosimeters, ranging from caps and hoods to headbands or face/neck wipes, were analysed to determine head exposure and personal air samplers with glass fibre filters or sampling tubes were used to quantify inhalation exposure. In total, the database contained more than 2900 individual values from 280 mixer/loaders and 344 applicators (Table 2).

In some cases the original exposure values had to be processed, e.g. in the case that values were below the limit of quantification (LOQ) (calculated with ½ LOQ) or below the limit of detection (LOD) (calculated with 0.01 μg/dosimeter). If the field recovery was below 70 %, a correction was applied. Other modifications were only done in rare cases, in which an extrapolation of the value was necessary (e.g. to extrapolate from short underwear to long-sleeved or long-legged underwear). Correction factors were established to account for the different head dosimeters used in the studies. For a conservative estimation of the whole head exposure the values derived from headbands were adjusted by a factor of 4, values from hats or caps by a factor of 2, values from hoods by a factor of 1.5 and values from face/neck wipes by a factor of 2. The exposure via inhalation was calculated from the amount of residue determined on the filter or tube of the air sampler and the flow rate of the air-sampling pump assuming a default breathing rate of 1.25 m3/h. This rate corresponds to normal work activity and is used as standard for estimating inhalation exposure of operators applying biocides (TNsG 2007).

In addition to exposure data further information regarding the pesticide product, the work task, the working conditions, the equipment and the operator were collected in the database. Overall, more than 50 parameters, which describe application conditions and might affect the extent of exposure were compiled and comprehensively studied.

3 Statistical evaluations

According to the application type and the spray equipment used in the selected studies, six different scenarios were identified—two scenarios for mixing/loading and four scenarios for application. Both mixing/loading scenarios, tank mixing/loading and knapsack mixing/loading, occurred in combination with hand-held equipment, while only tank mixing/loading took place when vehicle sprayers were used. Application was separated into scenarios for tractor/vehicle-mounted/-trailed equipment, either directed downwards (LCTM) or upwards (HCTM), and scenarios for hand-held sprayers, either directed downwards (LCHH) or upwards (HCHH).

For each scenario the following exposure variables were defined:

-

Inhalation exposure

-

Head exposure

-

‘Inner’ body exposure (actual body exposure, body exposure without using special personal protective equipment but with normal work clothes)

-

Total body exposure (potential body exposure, sum of inner and outer body dosimeter)

-

Protected hand exposure (hand exposure using personal protective equipment)

-

Total/unprotected hand exposure (potential hand exposure).

The exposure variables were separately modelled. As expected, the exposure data were approximately log-normally distributed. Therefore, a log-linear model was assumed to explain the exposure values X by A, e.g. the total amount of active substance used per operator per day, and a number of additional categorical factors Fi. The general form of the model was:

The logarithmic model has several desirable properties: the factors of the model contribute to the resulting exposure in a multiplicative way and the correlation between exposure and e.g. the total amount of active substance used can be described as sub-linear (exponent α < 1). This is assumed to be realistic as exposure tends to increase to a lesser extent when high amounts of active substance are used. However, a logarithmic model could also result in a superlinear dependency (α > 1, exposure increases to a higher extent when e.g. high amounts of active substance are applied) which is assumed to be implausible for an exposure model. Therefore, the exponent α was forced to be ≤1.

During model development the focus was set on selection of key factors which were expected to primarily determine the exposure and which were considered to be practicable for use in the authorisation procedure.

For the exposure calculation during mixing/loading the following factors were considered:

-

Formulation type

-

Total amount of active substance used

-

Number of containers handled

-

Number of mixing/loading tasks

-

Concentration of active substance in the product

-

Equipment (e.g. induction hopper)

-

Duration of mixing/loading

For the exposure calculation during application eight factors were chosen to be examined:

-

Formulation type

-

Total amount of active substance used

-

Concentration of active substance in spray solution

-

Equipment (e.g. cabin/no cabin)

-

Size of area treated

-

Droplet size

-

Cleaning

-

Duration of application

The impact of each factor alone and the impact of combinations of several factors (without interactions) were explored by the following process: Models describing the respective factors and their multiple combinations were fitted for each scenario by least squares regression and model diagnostics such as p value, R2 and AIC (Akaike information criterion) were evaluated. Based on the model diagnostics suitable factors were chosen for the respective scenarios by the expert group and the fitting process was started, i.e. the fit was inspected in detail and irrelevant factors were removed. This approach was chosen in order to make consistent and plausible choices for the different exposure variables and to avoid over-prediction. Relevant percentiles were then computed by quantile regression (Koenker 2005), a non-parametric method providing an independent estimate for every percentile which was found to be more robust than percentiles computed by linear regression. As recommended by EFSA (2010), the 75th percentile was used for all statistical issues concerning the development of the model. In parallel, the 95th percentile was considered in order to comply with possible future requirements for an acute risk assessment. In general the confidence in the estimate of a 95th percentile is lower than the confidence in the estimate of the 75th percentile.

4 Results

The results of the statistical analysis for the six scenarios are described below. Table 3 gives a summary of the results. The fit of the models and the model computations are presented in the project report which will be available on the BfR website.

4.1 M/L tank

The inhalation exposure and the dermal exposure to head, hands and body were clearly correlated with the total amount of active substance handled and the formulation type. Three categories of formulations can be distinguished:

-

WP formulations (were associated with relatively higher exposure)

-

WG formulations (were associated with relatively lower exposure) and

-

Liquid formulations (were associated with intermediate exposure, the data for the liquid formulations had to be pooled as no robust differentiation between EC (organic solvent-based) and SC/SL formulations (water-based) was possible).

The face/neck wipe data for operators who wore a face shield during mixing/loading form a subset and can be used as a scenario considering personal protective equipment (PPE) for the head (face shield plus hood).

4.2 M/L knapsack

Due to the small number of data for knapsack mixing/loading no modelling factors could be identified for predicting the exposure. Instead, it was proposed to calculate the 75th percentile. The 75th percentiles are based on the absolute exposure values and are assumed valid for up to 1.5 kg of active substance. A linear extrapolation for higher amounts will be possible as a ‘worst case’ assumption, because exposures are not expected to increase as much as this model predicts.

All head exposure data were obtained from face/neck wipes from operators wearing a face shield. As the exposure to the head is generally considered very low during that task it was accepted to apply the data for a PPE scenario (face shield and hood) and a non-PPE scenario.

4.3 LCTM application

Good correlation with the exposure was observed for the total amount of active substance and the size of the area treated, but using both as predictors was excluded since both factors are highly correlated. The impact of the area mainly referred to one exposure study for herbicide application in grapevine where small areas were treated but the resulting exposure was relatively high. The spray equipment used in the study was smaller than in other studies and the vehicles were not fitted with cabins. Therefore, it was decided to create a subset for herbicide application in high crops consisting of data from this study. As a further factor for the model the droplet size was identified. All nozzles for field crop sprayers that were classified for at least 50 % drift reduction have a so called “coarse droplet spectrum” (according to the definition developed by the Julius Kühn-InstitutFootnote 2). Operators using sprayers with this type of nozzles had a lower exposure than operators spraying with other types of nozzles. A clear impact on the exposure was also obvious when distinguishing between vehicles with a cabin (closed cabin or open cabin) and vehicles without. However, only the smaller spraying equipment used for herbicide applications in grapevine was not equipped with a cabin, a fact that is already addressed when considering this application scenario as a subset of LCTM application. A correlation with exposure was found for the concentration of active substance in the spray solution. Nevertheless, it was not considered as a factor as exposure was highly correlated with the total amount of active substance. The statistical analysis also revealed that cleaning is not a major factor for exposure. The total hand exposure of operators was comparable regardless of whether they conducted a cleaning operation or not.

4.4 HCTM application

The inhalation exposure and the exposure to the head and the body were clearly correlated with the total amount of active substance and the cabin status (cabin versus no cabin). The overall exposure of operators using vehicles with cabins was typically much lower than the exposure of operators using vehicles without cabins. For the unprotected/total hand exposure and the protected hand exposure conclusive correlations are less obvious. Nevertheless, it was decided to apply the same model for all exposure variables. The impact of cleaning was also analysed but a clear trend was not observed and cleaning was not considered further as a modelling factor. No data were available to distinguish between coarse and “non-coarse” droplet sizes.

4.5 LCHH application

Few data were available for hand-held applications in low crops. Therefore, it was decided to calculate the 75th percentile instead of modelling the exposure parameter(s). The 75th percentile is based on absolute measured exposure values and is assumed to be valid for up to 1.5 kg of active substance. Linear extrapolation for higher amounts will be possible as a ‘worst case’ assumption, because exposures are not expected to increase as far as this model predicts.

4.6 HCHH application

The exposure for HCHH application was highly correlated with the total amount of active substance handled. Additionally, the statistical evaluation indicated a strong dependency between the extent of exposure and certain application scenarios. The impact was referred to two exposure studies conducted in dense citrus orchards. The operators incurred significant exposure to the plant protection product while walking through the dense canopy. It was decided to define a subset for application in dense crops—a special scenario where intensive contact with sprayed crops cannot be avoided and exposure appears to be mainly based on dislodgeable spray deposits.

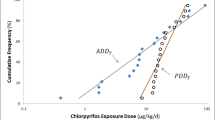

5 Validation

Independent validation is a very important issue during model development. The robustness and predictive capabilities of the new exposure model were tested using different strategies. The approach of cross validation (for an overview see Hastie et al. 2009) is to randomly remove a portion of the data (‘test set’) or single studies (one study per test set) and to compare the models obtained with the reduced data sets (‘training set’). The comparison of the reduced data sets and the original data set revealed that, in general, the resulting models were quite similar indicating robustness of the model. Additionally, study data which were collected in the database but could not be used for modelling because mixing/loading and application exposure were not measured separately were compared with the exposure estimates calculated with the model. The exposures predicted by the model were in good agreement with those measured.

Due to the structure of the model individual exposures for head, hands and body are predicted. To calculate the exposure for the whole body the respective percentiles are added which might result in a very conservative estimate presuming a certain extent (given by the percentiles) of exposure to all parts of the body. By comparing the sum of 75th percentile predictions with the 75th percentile of the observed whole body exposures in the studies it was investigated whether the model was too conservative. It turned out that both values were in reasonable agreement, which can be explained by the fact that the exposure in each scenario was dominated by one exposure variable.

More information on the validation of the model is given in the project report.

6 Predictive exposure model

The overall operator exposure (in mg/kg bw/d) was estimated by the models which corresponds to the exposure of a professional operator (wearing PPE or not) during a whole working day comprising mixing/loading (including rinsing the containers or vessels) and application of the PPP (including cleaning and maintenance of the equipment). It is composed of the dermal exposure DEO (including head (C), body (B) and hands (H)) and the inhalation exposure IEO from both tasks:

-

\( {\text{DE}}_{\text{O}} = {\text{DE}}_{{{\text{OML}}({\text{H}})}} + {\text{DE}}_{{{\text{OML}}({\text{B}})}} + {\text{DE}}_{{{\text{OML}}({\text{C}})}} + {\text{DE}}_{{{\text{OA}}({\text{H}})}} + {\text{DE}}_{{{\text{OA}}({\text{B}})}} + {\text{DE}}_{{{\text{OA}}({\text{C}})}} \)

-

\( {\text{IE}}_{\text{O}} = {\text{IE}}_{\text{OML}} + {\text{IE}}_{\text{OA}} \)

Each systemic exposure term results from the specific dermal exposure (Dx(y)) or specific inhalation exposure (Ix) taking account of the dermal or inhalative absorption of the active substance (DA; IA), a default body weight of the operator and, if necessary, the risk mitigation factor for using personal protective equipment (PPE):

-

\( {\text{DE}}_{\text{OX(Y)}} = \left( {{\text{D}}_{\text{X(Y)}} \times \left( {\text{PPE}} \right) \times {\text{DA}}}\right)/{\text{BW}} \)

-

\( {\text{IE}}_{\text{OX}} = \left( {{\text{I}}_{\text{X}} \times \left( {\text{PPE}} \right) \times {\text{IA}}} \right)/{\text{BW}} \)

The values for the specific exposure are based on the model equations or percentiles that resulted from the statistical analysis of the exposure studies (see Tables 4, 5). All calculations and model equations/percentiles were included in a calculator, an electronic tool, which, after entering the required information, gives an exposure estimate for every application scenario chosen. The calculator will be available on the BfR website; the respective user guidance is included in the project report.

In most of the selected studies the treated area corresponded to a typical workday. Therefore, the areas used in the model are based on the areas treated in the studies (based on the 75th percentile of the respective data; see Table 1). The default values for the area range from 50 ha for LCTM with normal equipment to 1 ha for knapsack sprayers in low or high crops as well as for HCHH in dense cultures. For HCTM application and LCTM application with small equipment (on small areas) an area of 10 ha is assumed and for hand-held application using tank sprayers with lances a default of 4 ha is used. However, the values for the area can be adjusted to specific conditions in different MS.

The calculation of the overall operator exposure starts with the assumption that, according to good agricultural practice, the operator is wearing at least one layer of work clothing completely covering the body, arms and legs when mixing/loading or applying pesticides (potential exposure can be calculated in addition, if necessary). It is calculated by combining the following specific exposures or variables:

-

Inhalation exposure (=potential inhalation exposure) ML, A

-

Total hand exposure (=potential hand exposure) ML, A

-

Head exposure (=potential head exposure) ML, A

-

‘Inner’ body exposure (=actual body exposure) ML, A.

According to the study data wearing work clothes reduces the body exposure by 85–98 % depending on the scenario considered. The actual dermal exposure (exposure to the skin beneath clothing and/or PPE) can be further reduced by considering standard personal protective equipment (PPE), e.g. a protective suit against chemicals using respective risk mitigation factors.

Exposure data for protected hands (using protective gloves continuously during mixing/loading or application) were available from the database and revealed an exposure mitigation of 89–99 % in comparison with bare hands. Hand exposure values were also considered to represent the ‘protected hand’ scenario when the operator was sitting in a closed cabin during application and only wore gloves when performing minor repair or maintenance work.

Head exposure data obtained by analysing face and neck wipes of operators who wore a face shield during mixing/loading were used to create a PPE scenario for the head. The model for head exposure during tank mixing/loading considers these data with an additional adjustment factor multiplying exposure when a face shield (+hood) is not used. The use of a face shield reduced head exposure by 98 %. No data were available for head exposure during knapsack mixing/loading without the use of a face shield. As the vast majority of these values were below the limit of quantification (LOQ) no correction was made to create a non-PPE scenario. Instead, the same values were used for the non-PPE and PPE scenarios.

In addition to the risk mitigation derived from the measured exposure data in the database default factors for specified PPE can be used for exposure calculation. The default factors in the BfR calculator are based on the risk mitigation factors used in the ‘German model’; however, the factors can be adapted to match e.g. with specific national conditions or recommendations by EFSA.

7 Data gaps

Despite the large number of data used for the development of the model, additional exposure values are needed to address certain scenarios. For example, exposure values from only three studies cover the scenario for knapsack mixing/loading and for hand-held applications in low crops. Due to the limited data (e.g. no exposure data for WP formulations and only a small range of total amount of active substance applied per day) no statistical model could be derived for these scenarios. Therefore, more data covering the different formulation types and a wider range of active substance applied per day are necessary to gain statistical power and to improve the models for these scenarios. In addition, data are completely lacking for high crop applications with knapsack sprayers and for low crop applications using tank sprayers with hand-held lances. As these data are not available it has to be assumed that exposure during hand-held application in low or high crops are similar irrespective of the exact equipment used.

A further gap consists in the lack of exposure data for mixing/loading WP formulations. The database only contains two studies with this formulation type, both conducted in Spain on hand-held application of the same insecticide in citrus. Hence, application conditions and equipment used were quite similar and the range of applied amount of active substance was small. Studies on WP formulations applied with tractor-associated equipment and more studies on WP formulations applied with hand-held equipment would be necessary to analyse and consider exposure factors in more detail.

8 Conclusions

A new exposure model for professional operators applying PPPs outdoors has been developed using previously unpublished field data that were subjected to a comprehensive statistical evaluation. The analysis of the data revealed that exposure mainly depends on the total amount of active substance used per day and can be further described by additional factors or particular use scenarios. The new model supports a tiered approach starting with estimating exposure for operators wearing at least one layer of clothing; risk mitigation by using personal protective equipment can be considered if the reference value is exceeded. As the majority of the studies were conducted in the last decade in several countries all over Europe the model reflects current application techniques and typical work conditions in Europe represented e.g. by work durations, field sizes or weather conditions in the studies. Therefore, the model is applicable both for national and for zonal authorisations of plant protection products including the approval of active substances in plant protection products in the EU.

The whole process of model development and the underlying data are described in more detail in a project report which will be available on http://www.bfr.bund.de. Calculators that are based on the new model (either on the level of the 75th percentile or on the level of the 95th percentile) will be available on that site, too. Updated versions of the model will be provided.

Notes

Compliance with the criteria of that guidance was also confirmed for studies conducted prior to 1997.

References

EFSA (European Food Safety Authority) (2010) Scientific opinion on preparation of a guidance document on pesticide exposure assessment for workers, operators, bystanders and residents. EFSA J 8(2):1501

Hamey PY (1992) Predictive operator exposure model (POEM): a user’s guide. MAFF pesticides safety division, York

Hastie T, Tibshirani R, Friedman J (2009) The elements of statistical learning-data mining, interference and prediction. In: Springer series in statistics, 2nd edn. Springer, Berlin

Koenker R (2005) Quantile regression. In: Chesher A, Jackson ME (eds) Conometric society monographs No. 38. Cambridge university press, Cambridge

Lundehn J-R, Westphal D, Kieczka H, Löchler-Bolz S, Maasfeld W, Pick E-D (1992) Uniform principles for safeguarding the health of applicators of plant protection products (Uniform principles for operator protection). Mitteilungen aus der Biologischen Bundesanstalt für Land- und Forstwirtschaft Berlin-Dahlem, Heft 277, Berlin

OECD (Organisation for Economic Co-operation and Development) (1997) Guidance document for the conduct of studies of occupational exposure to pesticides during agricultural application. OECD series on testing and assessment No. 9, Paris

Technical Notes for Guidance (TNsG) (2007) Human exposure to biocidal products. JRC website. http://ihcp.jrc.ec.europa.eu/our_activities/public-health/risk_assessment_of_Biocides/doc/TNsG/TNsG_ON_HUMAN_EXPOSURE/TNsG%20-Human-Exposure-2007.pdf

Acknowledgments

We wish to thank M. Tiramani from EFSA (European Food Safety Authority) and R. Gerritsen-Ebben and S. Spaan from TNO (Nederlandse Organisatie voor Toegepast Natuurwetenschappelijk Onderzoek-Dutch Organization for Applied Scientific Research) for their expert knowledge during the development of the model. We also wish to thank the members of the ECPA Operator, Bystander Exposure Expert Group for their contributions to the project development.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Großkopf, C., Mielke, H., Westphal, D. et al. A new model for the prediction of agricultural operator exposure during professional application of plant protection products in outdoor crops. J. Verbr. Lebensm. 8, 143–153 (2013). https://doi.org/10.1007/s00003-013-0836-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00003-013-0836-x