Abstract

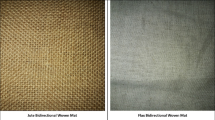

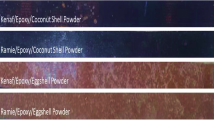

Bio-composites are a group of composite materials that use polymer as the matrix and fiber as reinforcement for the matrix. Due to their unique synergistic multifunction through incorporation of multiple components into one compatible entity, they have found broad applications in electronic, magnetic, optical, and electrochromic. Existing works do not focus on use of natural fiber reinforcement along with natural nanofillers. The goal of this study is to find and evaluate the properties of bio-nanocomposites made using different combinations of jute and flax fiber mat as reinforcement, epoxy as matrix, and coconut shell powder and eggshell powder as nanofiller. Jute-reinforced nanocomposites were found to absorb more water than other nanocomposite samples. It also had higher surface roughness than other nanocomposites with jute/epoxy/coconut shell having highest surface roughness of 0.08. Jute/epoxy/eggshell had the highest tensile strength, Young’s modulus, and elongation at break of 34.3291 MPa, 782.5489 MPa, and 4.3885% respectively. Flexural strength was highest for jute/epoxy/coconut shell at 32.3690 MPa. Impact strength was also highest for jute/epoxy/coconut shell at 8.9 kJ/m2. From the SEM analysis, it was found that jute showed minimum debonding with matrix phase due to rough surface and better wettability with matrix phase which provided better strength than flax fiber hence it performed better in mechanical testing. Thus, it was found that jute fiber provided better strength to the nanocomposite along with coconut shell powder making it a slightly better alternative than the other nanocomposite sample.

Similar content being viewed by others

Data availability

Not applicable.

References

Nurazzi NM et al (2021) A review on natural fiber reinforced polymer composite for bullet proof and ballistic applications. Polymers 13(4):646. https://doi.org/10.3390/POLYM13040646

Chandramohan D, Marimuthu K (2011) Applications of natural fiber composites for replacement of orthopaedic alloys. In: International Conference on Nanoscience, Engineering and Technology (ICONSET 2011). IEEE, pp 137–145. https://doi.org/10.1109/ICONSET.2011.6167942

Mahir FI, Keya KN, Sarker B, Nahiun KM, Khan RA (2019) A brief review on natural fiber used as a replacement of synthetic fiber in polymer composites. Mater Eng Res 1(2):86–97. https://doi.org/10.25082/MER.2019.02.007

Sam ST, Nuradibah MA, Chin KM, Hani N (2016) Current application and challenges on packaging industry based on natural polymer blending. In: Natural polymers: Industry techniques and applications, pp 163–184. https://doi.org/10.1007/978-3-319-26414-1_6

Chandgude S, Salunkhe S (2021) In state of art: Mechanical behavior of natural fiber-based hybrid polymeric composites for application of automobile components. Polym Compos 42(6):2678–2703. https://doi.org/10.1002/PC.26045

Yan L, Kasal B, Huang L (2016) A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos B Eng 92:94–132. https://doi.org/10.1016/J.COMPOSITESB.2016.02.002

Balakrishnan P, John MJ, Pothen L, Sreekala MS, Thomas S (2016) Natural fibre and polymer matrix composites and their applications in aerospace engineering. In: Advanced composite materials for aerospace engineering. Woodhead Publishing, pp 365–383. https://doi.org/10.1016/B978-0-08-100037-3.00012-2

Mohammed L, Ansari MN, Pua G, Jawaid M, Islam MS (2015) A review on natural fiber reinforced polymer composite and its applications. Int J Polym Sci 2015. https://doi.org/10.1155/2015/243947

Koniuszewska AG, Kaczmar JW (2016) Application of polymer based composite materials in transportation. Prog Rubber Plast Recycl Technol 32(1):1–24. https://doi.org/10.1177/147776061603200101

Saba N, Jawaid M (2017) Epoxy resin based hybrid polymer composites. Hybrid Polym Compos Mater 57–82. https://doi.org/10.1016/B978-0-08-100787-7.00003-2

Mittal V, Saini R, Sinha S (2016) Natural fiber-mediated epoxy composites – a review. Compos B Eng 99:425–435. https://doi.org/10.1016/J.COMPOSITESB.2016.06.051

Saba N, Jawaid M, Alothman OY, Paridah MT, Hassan A (2015) Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. J Reinf Plast Compos 35(6):447–470. https://doi.org/10.1177/0731684415618459

Vinay SS, Sanjay MR, Siengchin S, Venkatesh CV (2021) Effect of Al2O3 nanofillers in basalt/epoxy composites: mechanical and tribological properties. Polym Compos 42(4):1727–1740. https://doi.org/10.1002/pc.25927

Amjad A, Awais H, Anjang Ab Rahman A, Abidin MSZ (2021) Effect of nanofillers on mechanical and water absorption properties of alkaline treated flax/PLA fibre reinforced epoxy hybrid nanocomposites. Adv Compos Mater 31(4):351–369. https://doi.org/10.1080/09243046.2021.1993563

Amjad A, Anjang Ab Rahman A, Abidin MSZ (2022) Effect of nanofillers on mechanical and water absorption properties of alkaline treated jute fiber reinforced epoxy bio nanocomposites. J Nat Fibers 19(16):14592–14608. https://doi.org/10.1080/15440478.2022.2068171

Dhanasekar K, Krishnan AM, Kaliyaperumal G, De Poures MV, Chandramohan P, Parthipan N, Negash K (2023) Influences of nanosilica particles on density, mechanical, and tribological properties of sisal/hemp hybrid nanocomposite. Adv Polym Technol 2023. https://doi.org/10.1155/2023/3684253

Nejat T, Naghdi R, Nadali E, Asgharzadeh Avajeghi P, Jafari R (2023) Effects of nanoclay cloisite 20A and alkali treatments on structure-property relationships of bagasse/recycled polypropylene nanocomposites. J Thermoplast Compos Mater. https://doi.org/10.1177/08927057231170802

Jha MK, Das PP, Pandey V, Gupta P, Chaudhary V, Gupta S (2022) Water immersion aging of polymer composites: architectural change of reinforcement, mechanical, and morphological analysis. Biomass Convers Biorefin:1–15

Chaudhary V, Bajpai PK, Maheshwari S (2020) Effect of moisture absorption on the mechanical performance of natural fiber reinforced woven hybrid bio-composites. J Nat Fibers 17(1):84–100. https://doi.org/10.1080/15440478.2018.1469451

Abdel-Rahim RH, Mohammed RA (2019) Experimental investigation of some properties of epoxy reinforced by egg shell particles. Int J Mech EngTechnol 10(1):152–163

Bhaskar J, Bhaskar J, Singh VK (2013) Water absorption and compressive properties of coconut shell particle reinforced-epoxy composite. J Mater Environ Sci 4(1):113–118 (https://www.researchgate.net/publication/268805452)

Gideon R, Atalie D (2022) Mechanical and water absorption properties of jute/palm leaf fiber-reinforced recycled polypropylene hybrid composites. Int J Polym Sci 2022. https://doi.org/10.1155/2022/4408455

Sanjay MR, Yogesha B (2016) Study on water absorption behaviour of jute and kenaf fabric reinforced epoxy composites: hybridization effect of E-glass fabric. Int J Compos Mater 6(2):55–62. https://doi.org/10.5923/J.CMATERIALS.20160602.03

Biswas S, Shahinur S, Hasan M, Ahsan Q (2015) Physical, mechanical and thermal properties of jute and bamboo fiber reinforced unidirectional epoxy composites. Procedia Eng 933–939. https://doi.org/10.1016/j.proeng.2015.05.118

Hunain MB, Alnomani SN, Razzaq Q (2021) An investigation of tensile and thermal properties of epoxy polymer modified by activated carbon particle. IOP Conf Ser Mater Sci Eng 1094(1):012164

Awais H, Nawab Y, Amjad A, Anjang A, MdAkil H, ZainolAbidin MS (2019) Effect of comingling techniques on mechanical properties of natural fibre reinforced cross-ply thermoplastic composites. Compos B Eng 177:107279. https://doi.org/10.1016/J.COMPOSITESB.2019.107279

Saw SK, Purwar R, Nandy S, Ghose J, Sarkhel G (2013) Fabrication, characterization, and evaluation of Luffa cylindrica fiber reinforced epoxy composites. Bioresources 8(4):4805–4826. https://doi.org/10.15376/BIORES.8.4.4805-4826

Chaudhary V, Sahu R, Manral A, Ahmad F (2020) Comparative study of mechanical properties of dry and water aged jute/flax/epoxy hybrid composite. Mater Today Proc 25:857–861. https://doi.org/10.1016/J.MATPR.2019.11.053

Amjad A, Abidin MSZ, Alshahrani H, Ab Rahman AA (2021) Effect of fibre surface treatment and nanofiller addition on the mechanical properties of flax/PLA fibre reinforced epoxy hybrid nanocomposite. Polymers 13(21):3842. https://doi.org/10.3390/POLYM13213842

Chaudhary V, Bajpai PK, Maheshwari S (2017) Studies on mechanical and morphological characterization of developed jute/hemp/flax reinforced hybrid composites for structural applications. J Nat Fibers 15(1):80–97. https://doi.org/10.1080/15440478.2017.1320260

Ashok KG, Kalaichelvan K, Damodaran A (2020) Effect of nano fillers on mechanical properties of luffa fiber epoxy composites. J Nat Fibers 19(4):1472–1489. https://doi.org/10.1080/15440478.2020.1779898

Madhu P, Bharath KN, Sanjay MR, Arpitha GR, Saravanabavan D (2021) Effect of nano fillers on glass/silk fibers based reinforced polymer composites. Mater Today: Proc 46:9032–9035. https://doi.org/10.1016/j.matpr.2021.05.383

Shunmugasundaram M, Kumar AP, Baig MAA, Kasu Y (2021) Investigation on the effect of nano fillers on tensile property of neem fiber composite fabricated by vacuum infused molding technique. IOP Conf Ser Mater Sci Eng 1057(1):012019. https://doi.org/10.1088/1757-899x/1057/1/012019

Wang H, Memon H, Hassan EAM, Miah MS, Ali MA (2019) Effect of jute fiber modification on mechanical properties of jute fiber composite. Materials 12(8):1226. https://doi.org/10.3390/MA12081226

Lim KS, Mariatti M, Kamarol M, Ghani ABA, Shafi Halim H, Abu Bakar A (2019) Properties of nanofillers/crosslinked polyethylene composites for cable insulation. J Vinyl Addit Technol 25(S1):E147–E154. https://doi.org/10.1002/VNL.21671

Nurul MS, Mariatti M (2013) Effect of hybrid nanofillers on the thermal, mechanical, and physical properties of polypropylene composites. Polym Bull 70(3):871–884. https://doi.org/10.1007/S00289-012-0893-9

Ramasubbu R, Madasamy S (2020) Fabrication of automobile component using hybrid natural fiber reinforced polymer composite. J Nat Fibers 19(2):736–746. https://doi.org/10.1080/15440478.2020.1761927

Verma D, Goh KL (2021) Effect of mercerization/alkali surface treatment of natural fibres and their utilization in polymer composites: mechanical and morphological studies. J Compos Sci 5(7):175. https://doi.org/10.3390/JCS5070175

Khan Z, Yousif BF, Islam M (2017) Fracture behaviour of bamboo fiber reinforced epoxy composites. Compos B Eng 116:186–199. https://doi.org/10.1016/J.COMPOSITESB.2017.02.015

Gupta MK, Srivastava RK (2017) Studies on mechanical, thermal and dynamic mechanical analysis of Jute fiber reinforced epoxy composite. Indian J Fibre Text Res 42:64–71. Available: https://www.researchgate.net/publication/288838082. Accessed March 2017

Kavalastrahiremath SC, Siddeswarappa B, Channalli M (2016) Evaluation of tensile and flexural properties of coconut coir and coconut shell powder reinforced epoxy composites. Int J Eng Res 5(2):36–40

Cerbu C (2015) Mechanical characterization of the flax/epoxy composite material. Procedia Technol 19:268–275. https://doi.org/10.1016/J.PROTCY.2015.02.039

Wang L, He C (2022) “Water resistance and flexural properties of three nano-fillers reinforced corn straw/polyvinyl chloride composites. J Adhes Sci Technol 36(20):2199–2212. https://doi.org/10.1080/01694243.2021.2004740

Hallad SA et al (2022) Investigation of flexural properties of epoxy composite by utilizing graphene nanofillers and natural hemp fibre reinforcement. Polym Polym Compos 30:1–11. https://doi.org/10.1177/09673911221093646

Boopalan M, Niranjanaa M, Umapathy MJ (2013) Study on the mechanical properties and thermal properties of jute and banana fiber reinforced epoxy hybrid composites. Compos B Eng 51:54–57. https://doi.org/10.1016/J.COMPOSITESB.2013.02.033

Abd-El-baky MA, Attia MA, Abdelhaleem MM, Hassan MA (2020) Mechanical characterization of hybrid composites based on flax, basalt and glass fibers. J Compos Mater 54(27):4185–4205

Singh JIP, Singh S, Dhawan V (2020) Effect of alkali treatment on mechanical properties of jute fiberreinforced partially biodegradable green composites using epoxy resin matrix. Polym Polym Compos 28(6):388–397. https://doi.org/10.1177/0967391119880046

Bensadoun F, Depuydt D, Baets J, Verpoest I, van Vuure AW (2017) Low velocity impact properties of flax composites. Compos Struct 176:933–944. https://doi.org/10.1016/J.COMPSTRUCT.2017.05.005

Rafiq A, Merah N, Boukhili R, Al-Qadhi M (2017) Impact resistance of hybrid glass fiber reinforced epoxy/nanoclay composite. Polym Test 57:1–11. https://doi.org/10.1016/J.POLYMERTESTING.2016.11.005

Landowski M, Strugała G, Budzik M, Imielińska K (2017) Impact damage in SiO2 nanoparticle enhanced epoxy – carbon fibre composites. Compos B Eng 113:91–99. https://doi.org/10.1016/J.COMPOSITESB.2017.01.003

Kamatchi T, Saravanan R, Rangappa SM, Siengchin S (2023) Effect of filler content and size on the mechanical properties of graphene-filled natural fiber-based nanocomposites. Biomass Convers Biorefin 13:11311–11320. https://doi.org/10.1007/s13399-023-03911-9

Author information

Authors and Affiliations

Contributions

Sidharth Radhakrishnan: writing—original manuscript; Vijay Chaudhary, Shashi Prakash Dwivedi, Pallav Gupta, Sumit Gupta, and Bhasha Sharma: ideas, conceptualization, supervision, Anas Khan: writing—reviewing and editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Radhakrishnan, S., Khan, A., Dwivedi, S.P. et al. Studies on mechanical, thermal, and water immersion of plant and animal wastage nanofiller–based bio-fiber-reinforced composites. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04788-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04788-4