Abstract

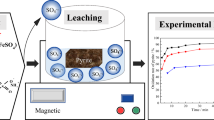

Numerous studies have demonstrated that Na2SO4 can significantly inhibit the reduction of iron oxide in the selective reduction process of laterite nickel ore. FeS generated in the process plays an important role in selective reduction, but the generation process of FeS and its inhibition mechanism on iron reduction are not clear. To figure this out, X-ray diffraction and scanning electron microscopy analyses were conducted to study the roasted ore. The results show that when Na2SO4 is added in the roasting, the FeO content in the roasted ore increases accompanied by the emergence of FeS phase. Further analysis indicates that Na2S formed by the reaction of Na2SO4 with CO reacts with SiO2 at the FeO surface to generate FeS and Na2Si2O5. As a result, a thin film forms on the surface of FeO, hindering the contact between reducing gas and FeO. Therefore, the reduction of iron is depressed, and the FeO content in the roasted ore increases.

Similar content being viewed by others

References

Y.J. Li, H.C. Yu, D.Q. Wang, W.X. Yin, and Y.S. Bai, The current status of laterite ore resources and its processing technology, Met. Mine, (2010), No. 11, p. 5.

M.J. Rao, G.H. Li., T. Jiang, J. Luo, Y.B. Zhang, and X.H. Fan, Carbothermic reduction of nickeliferous laterite ores for nickel pig iron production in China: a review, JOM, 65(2013), No. 11, p. 1573.

C.Y. Wang, F. Yin, Y.Q. Chen, Z. Wang, and J. Wang, Worldwide processing technologies and progress of nickel laterites, Chin. J. Nonferrous Met., 18(2008), No. S1, p. 1.

A.D. Dalvi, W.G. Bacon, and R.C. Osborne, The Past and the Future of Nickel Laterites, 2004. http://wenku.baidu.com/view/fd6841293169a4517723a33f.html

G.H. Li, T.M. Shi, M.J. Rao, T. Jiang, and Y.B. Zhang, Beneficiation of nickeliferous laterite by reduction roasting in the presence of sodium sulfate, Miner. Eng., 32(2012), p. 19.

J. Kim, G. Dodbiba, H. Tanno, K. Okaya, S. Matsuo, and T. Fujita, Calcination of low-grade laterite for concentration of Ni by magnetic separation, Miner. Eng., 23(2010). No. 4, p. 282.

G.L. Zheng, D.Q. Zhu, J. Pan, Q.H. Li, Y.M. An, J.H. Zhu, and Z.H. Liu, Pilot scale test of producing nickel concentrate from low-grade saprolitic laterite by direct reduction-magnetic separation, J. Cent. South Univ., 21(2014), No. 5, p. 1771.

B. Li, H. Wang, and Y.G. Wei, The reduction of nickel from low-grade nickel laterite ore using a solid-state deoxidisation method, Miner. Eng., 24(2011), No. 14, p. 1556.

W. Liang, H. Wang, J.G. Fu, and Z.X. He, High recovery of ferro-nickel from low grade nickel laterite ore, J. Cent. South Univ., 42(2011), No. 8, p. 2173.

G.H. Li, M.J. Rao, T. Jiang, Q.Q. Huang, T.M. Tang, and Y.B. Zhang, Innovative process for preparing ferronickel materials from laterite ore by reduction roasting-magnetic separation, Chin. J. Nonferrous Met., 21(2011), No. 12, p. 3137.

D.H. Huang, J.L. Zhang, C.C. Lin, and R. Mao, Production of ferro-nickel granules from nickel laterite ore/coal composite briquettes by direct reduction, J. Univ. Sci. Technol. Beijing, 33(2011), No. 12, p. 1442.

Z.C. Cao, T.C. Sun, H.F. Yang, J.J. Wang, and X.D. Wu, Recovery of iron and nickel from nickel laterite ore by direct reduction roasting and magnetic separation, J. Univ. Sci. Technol. Beijing, 32(2010), No. 6, p. 708.

T.C. Sun, Y.N. Ji, and M. Jiang, Influence mechanism of different types of coal on selective nickel reduction in nickel laterite reduction roasting, J. Univ. Sci. Technol. Beijing, 33(2011), No. 10, p. 1197.

M. Jiang, T.C. Sun, Z.G. Liu, J. Kou, N. Liu, Y.Y. Cao, and S.Y. Zhang, Effects of coal types and additives on selective direct reduction of nickel laterite, Min. Metall. Eng., 32(2012), No. 5, p. 77.

G.H. Li, M.J. Rao, T. Jiang, T.M. Shi, and Q.Q. Huang, Reduction roasting-magnetic separation mechanisms of nickelferous laterite ore in presence of sodium salts, Chin. J. Nonferrous Met., 22(2012), No. 1, p. 274.

T.C. Sun, M. Jiang, Z.G. Liu, N. Liu, S.Y. Zhang, J. Kou, and C.Y. Xu, Research on the effect of additive on selective reduction of the laterite ores with low nickel and high iron content, J. China Univ. Min. Technol., 42(2013), No. 5, p. 838.

D.Q. Zhu, Y. Cui, K. Vining, S. Hapugoda, J. Douglas, J. Pan, and G.L. Zheng, Upgrading low nickel content laterite ores using selective reduction followed by magnetic separation, Int. J. Miner. Process, 106-109(2012), p. 1.

M. Valix and W.H. Cheung, Effect of sulfur on the mineral phases of laterite ores at high temperature reduction, Miner. Eng., 15(2002), No. 7, p. 523.

J. Lu, S.J. Liu, J. Shangguan, W.G. Du, F. Pan, and S. Yang, The effect of sodium sulphate on the hydrogen reduction process of nickel laterite ore, Miner. Eng., 49(2013), p. 154.

M. Jiang, T.C. Sun, Z.G. Liu, J. Kou, N. Liu, and S.Y. Zhang, Mechanism of sodium sulfate in promoting selective reduction of nickel laterite ore during reduction roasting process, Int. J. Miner. Process, 123(2013), p. 32.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Zg., Sun, Tc., Wang, Xp. et al. Generation process of FeS and its inhibition mechanism on iron mineral reduction in selective direct reduction of laterite nickel ore. Int J Miner Metall Mater 22, 901–906 (2015). https://doi.org/10.1007/s12613-015-1148-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1148-1