Abstract

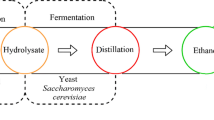

Acid and base saccharification (hydrolysis) are simple and direct ways to convert biomass into fermentable sugars to be used for the production of bioethanol as renewable liquid fuel. In this study, the marine green alga (Ulva fasciata) was converted to sugars by acid and base hydrolysis (Na OH, ammonium oxalate, HCL, and H2SO4) at different concentrations (1, 3, 5, 7 %) at 121 °C for one, two and three rounds in autoclave. Biological hydrolysis of alga was also done by bacterial growth and enzymatic hydrolysis of alga. The maximum amount of sugars was 700 ± 26.10 mg sugar/g alga biomass Ulva fasciata at one round of autoclave with 3 % sulphuric acid. The sugar ratio was 640.96 ± 9.6 mg sugar/g algal biomass Ulva fasciata that treated by a bacterial strain (Bacillus subtilis SH04). Sugar yields from Ulva fasciata by amylase partially purified from Bacillus subtilis SH04 (B4) and Bacillus cereus SH06 (B6) followed by autoclaving for one round gave 458.27 ± 6.55 and 516.07 ± 5.17 mg sugar/g algal biomass, respectively. The ethanol efficiency using Saccharomyces cerevisiae SH02 was 78.3 % ± 6 with 5 % sugar concentration that produced by acid hydrolysis. Ethanol production was 55.9 % ± 5.2 after enzymatic hydrolysis of alga and fermentation by Saccharomyces cerevisiae SH02.

Similar content being viewed by others

References

Abdel-Fattah AF, Edress M (1972) A study on the polysaccharide content of Ulva lactuca. Qualitas Plantarum Et Materiae Vegetabiles 6:15–22

Aehle W, Misset O (1999) Enzymes for industrial applications. In: Rehm HJ, Reed G (eds) Biotechnology, 2nd edn. Wiley-VCH, Germany

Aleem AA (1993) The marine algae of Alexandria (ED). Faculty of science. Alexandria university, Egypt

Aro N, Pakula T, Penttiillae M (2005) Transcriptional regulation of plant cell wall degradation by filamentous fungi. FEMS Microbiol Rev 29:719–739

Azad MA, Bae JH, Kim JS, Lim JK, Song KS, Shin BS, Kim HR (2009) Isolation and characterization of a novel thermo stable alpha-amylase from Korean pine seeds. N Biotechnol 26:143–149

Beveridge MCM, Sikdar PK, Frerichs GN, Millar S (1991) The ingestion of bacteria in suspension by the common carp Cyprinus carpio L. J of Fish Biology 39:825–831

Binder JB, Raines RT (2010) Fermentable sugars by chemical hydroysis of biomass. Proc Natl Acad Sci 107:4516–4521

Bisaria VS (1991) Bioprocessing of agro-residues to glucose and chemicals. In: Martin AM (ed) Elsevier, London pp 210–213

Bixler HJ, Porse H (2010) A decade of change in the seaweed hydrocolloids industry. J Appl Phycol 23:321–335

Bryhmi E (1978) Quantitative differences between polysaccharide compositions in normal differentiated Ulva mutabilis undifferentiated mutant lumpy. Phycologia 17:119–124

Çaylak K, Sukan F (1998) Comparison of different production process for bioethanol. Turk J Chem 22(4):351–359

Charitha MD, Kumar MS (2012) Production, optimization and partial purification of cellulase by Aspergillus niger fermented with paper and timber sawmill industrial wastes. Microbiol Biotech Res 2:120–128

Devakia T, Sathivel A, Rao H, Raghavendranc B (2009) Stabilization of mitochondrial and microsomal function by polysaccharide of Ulva lactuca on d-Galactosamine induced hepatitis in rats. Chem Biol Interact 177:83–88

Dubois M, Gilles KA, Hamilton JK, PA Rebers, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Duke CS, Litaker W, Ramus J (1989) Effects of the temperature, nitrogen supply and tissue nitrogen on ammonium uptake rates of the Chlorophyte seaweeds Ulva curvata and Codium decorcatum. J Phycol 25:113–120

El-Sheekh MM, Hamouda RA (2016) Lipids extraction from the green alga Ankistrodesmus falcatus using different methods. Rend Fis Acc Lincei 1–7. doi:10.1007/s12210-016-0528-4

Fakroddin Md, Abdul Quayum Md, Monzurmorsned A, Naiyyum C (2012) Analysis of key factors affecting ethanol production by Saccharomyces cerevisiae IFST-072011. Biotechnology 11(4):248–252

Ferreira OF, Montijo NA, Martins ES, Mutton MJR (2015) Production of α-amylase by solid state fermentation by Rhizopus oryzae. Afr J Biotechnol 14(7):622–628

Foreman PK, Brown D, Dankmeyer L, Dean R, Diener S, Dunn Coleman NS, Goedegebuur F, Houfek TD, England GJ, Kelley AS, Meerman HJ, Mitchell T, Mitchinson C, Olivares HA, Teunissen PJM, Yao J, Ward M (2003) Transcriptional regulation of biomass degrading enzymes in the filamentous fungus Trichoderma. J Biol Chem 278:31988–31997

Fujita RM (1985) The role of nitrogen status in regulating transient ammonium uptake and nitrogen storage by macroalgae. J Exp Marine Biol Ecol 92:283–301

Govindaswamy S, Vane LM (2010) Multi-stage continuous culture fermentation of glucose–xylose mixtures to fuel ethanol using genetically engineered Saccharomyces cerevisiae 424S. Bioresour Technol 101:1277–1284

Gunasekaran P, Karunakaran T, Kasthuribal M (1986) Fermentation pattern of Zymomonas mobilis strains on different substrates a comparative study. J Biosci 10(2):181–186

Hamouda RA, Hussein MH, Hamza HA, Yeheia DS (2013) Production of bioethanol from macrogreen algae. Egypt journal of Botany. 3rd International Conference pp 235–246

Hamouda RA, Hussein MH, El El-Naggar N (2015) Potential value of red and brown seaweed for sustainable bioethanol production. Bangladesh J Bot 44:565–570

Jacob MB, Gerstein MJ (1960) Handbook of Microbiology. D. Van Nostrand Co., Inc., Princeton New Jersey

Kadar ZS, Thomsen AB (2010) Biofuel production from macroalage, poster presented at 32nd symposium on Biotechnology for fuels and chemicals, 19–22 April, 2010, FL, USA

Knoshaug EP, Darzins A (2011) Algal biofuels: the process. Chem Eng Progr 107:37–47

Krishnaveni S, Balasubramanian T, Sadasivam S (1984) Sugar distribution in sweet stalk sorghum. Food Chem 15:229–232

Kumar S, Tamura K, Nei M (2004) MEGA3: integrated software for molecular evolutionary genetics analysis and sequence alignment. Brief Bioinform 5:150–163

Kumar CS, Ganesan P, Bhaskar N (2008) In vitro antioxidant activities of three selected brown seaweeds of India. Food Chem 107:707–713

Kumar RS, Shankar T, Anandapandian KTK (2011) Characterization of alcohol resistant yeast Saccharomyces cerevisiae isolated from Toddy. Int Res J Microbiol 2(10):399–405

Lahaye M, Axelos MAV (1993) Gelling properties of water soluble polysaccharides from proliferating marine green seaweeds (Ulva spp.). Carbohydr Polym 22:261–265

Lahaye M, Kaeffer B (1997) Seaweed dietary fibres: structure, physico-chemical and biological properties relevant to intestinal physiology. Sciences des Aliments 17:563–584

Lee YY, Iyer P, Torget RW (1999) Dilute-acid hydrolysis of lignocellulosic biomass: recent progress in bioconversion of lignocellulosics. Adv Biochem Eng Biotechnol 65:93–115

Lenihan P, Orozco AO, Neill E, Ahmad MNM, Rooney DW, Walker GM (2010) Dilute acid hydrolysis of lignocellulosic biomass. Chem Eng J 156:395–403

Lin LL, Hsu WH (1997) A gene encoding for an alpha-amylase from thermophilic Bacillus sp. strain TS-23 and its expression in Escherichia coli. J Appl Microbiol 82:325–334

Lynd LR (1996) Overview and evaluation of fuel ethanol from cellulosic biomass: technology, economics, the environment, and policy. Annu Rev Energy Environ 21:403–465

Mata TM, Martins ANA, Caetano NS (2010) Microalgae for biodiesel production and other applications: a review. Renew Sustain Energy Rev 14:217. doi:10.1016/j.rser.2009.07.020

McHugh DJ (1987) Production and utilization of products from commercial seaweeds. FAO Fish Tech Paper 288:1–189

Morand P, Briand X (1996) Excessive growth of macroalgae: a symptom of environmental disturbance. Bot Mar 39:491–516

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Murata M, Nakazoe J (2001) Production and use of marine algae in Japan. Jarq-Jpn Agric Res Quart 35:281–290

Niranjane AJ, Madhou P, Stevenson TW (2007) The effect of carbohydrate carbon sources on the production of cellulase by Phlebia gigantean. Enzyme Microbial Technol 40:1464–1468

Nokov N, Marinova M, Dimitrova-Konaklieve S (1984) Chemical composition and biology of Black sea seaweed Ulva rigida Ag. Part 1. Formatriya (Sofia) 34:24–26

Pádua Md, Sérgio P, Fontoura G, Mathias AL (2004) Chemical Composition of Ulvaria oxysperma (Kützing) Bliding, Ulva lactuca (Linnaeus) and Ulva fasciata. Delile 47:49–55

Pengzhan Y, Quanbin Z, Ning L, Zuhong X, Yanmei W, Zhien L (2003) Polysaccharides from Ulva pertusa (Chlorophyta) and preliminary studies on their antihyperlipidemia activity. Appl Phycol 15:21–27

Priest FG (1977) Extracellular enzyme synthesis in the genus Bacillus. Bacteriol Rev 41:711–753

Priyadarshani I, Rath B (2012) Commercial and industrial applications of micro algae—A review. J Algal Biomass Utln 3(4):89–100

Pultz O, Gross W (2004) Valuable products from biotechnology of microalgae. Appl Microbiol Biotechnol 65:635–648

Rainey FA, Ward-Rainey N, Kroppenstedt RM, Stackbrandt E (1996) The genus nocardiopsis represents a phylogenetically coherent taxon and a distinct Actinomycete Lineage: proDosal of Nocardiomaceae fam. nov. Int J Sys Bacteriol 46:1088–1092

Rajagopalan G, Krishnan C (2008) Alpha-amylase production from catabolite derepressed Bacillus subtilis KCC103 utilizing sugarcane bagasse hydrolysate. Bioresour Technol 99:3044–3050

Ross AB, Jones JM, Kubacki ML, Bridgeman T (2008) Classification of macroalgae as fuel and its thermochemical behavior. Bioresource Technol 99:6494–6504

Saha BC, Iten LB, Cotta MA, Wu YV (2005) Dilute acid pretreatment, enzymatic saccharification and fermentation of wheat straw to ethanol. Proc Biochem 40:3693–3700

Sanchez G, Pilcher L, Roslander C, Modig T, Galbe M, Liden G (2004) Dilute acid hydrolysis for fermentation of the Bolivian straw material Paja Brava. Bioresource Technol 93:249–256

Scott SA, Davey MP, Dennis JS, Horst I, Howe CJ, Lea-Smith DJ, Smith AG (2010) Biodiesel from algae: challenges and prospects. Curr Opin Biotechnol 21:277–286

Siddhanta AK, Goswami AM, Ramavat BK, Mody KH, Mairh OP (2001) Water soluble polysaccharides of marine algal species of Ulva (Ulvales, Chlorophyta) of Indian waters. Indian J of Mar Sci 30:166–172

Singh S, Kate BN, Banerjee UC (2005) Bioactive compounds from cyanobacteria and microalgae an overview. Crit Rev Biotechnol 25:73–95

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Taherzadeh MJ, Karimi K (2007) Enzyme-based hydrolysis processes for ethanol from lignocelluloses materials: a review. BioResources 2(4):707–738

Tahir A, Aftab M, Farasat T (2010) Effect of cultural conditions on ethanol production by locally isolated Saccharomyces cerevisiae BIO-07. J Appl Pharmacol 3:72–78

Taylor WS (1985) Marine algae of the eastern tropical and subtrobical coasts of Americas. ANN Arbor the university of Michigan press

Teather RM, Wood PJ (1982) Use of Congo red-polysaccharide interactions in enumeration and characterization of cellulolytic bacteria from the bovine rumen. Appl Environ Microbiol 43:777–780

Thompson JD, Higgins DG, Gibson TJ (1994) CLUSTAL W: improving the sensitivity of progressive multiple sequence alignment through sequence weighting, position-specific gap penalties and weight matrix choice. Nucl Acids Res 22:4673–4680

Thomsen AB, Arvaniti E, Xu J, Oleskowicz-Popiel P, Frenqvist T, Schultz-Jensen N, Kádár Z, Jensen M, Thomsen ST, Thygessen A (2010) Pretreatment technologies for production of 2G bioethanol from agricultural waste and crops. Speech at: 11th European Workshop on Lignocellulosic and Pulp, Hamburg, Germany, 16–19 August

Tseng CK (2001) Algal biotechnology industries and research activities in China. J Appl Phycol 13:375–380

Wijffels RH, Barbosa MJ (2010) An outlook on microalgal biofuels. Science 329:796–799

Wolfgang A (2007) Enzyme in industry: production and applications. Wiley-VCH, Weinheim

Xian Q, Lee YY, Pettersson PO, Torget RW (2003) Heterogeneous aspects of acid hydrolysis of alpha-cellulose. Appl Biochem and Biotech 105–108: 505–514. http://www.ncbi.nlm.nih.gov

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamouda, R.A., Sherif, S.A., Dawoud, G.T.M. et al. Enhancement of bioethanol production from Ulva fasciata by biological and chemical saccharification. Rend. Fis. Acc. Lincei 27, 665–672 (2016). https://doi.org/10.1007/s12210-016-0546-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12210-016-0546-2