Abstract

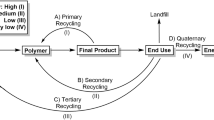

Synthetic plastics generate major problems in landfills after their consumption for occupying high volumes and difficult the decomposition of other organic materials. In addition, they are also responsible for impacts on the marine ecosystem. Because of this, the need for cleaner products and process is increasing. Among a variety of existing bioplastics, those derived from cleaner fermentation processes such as polyhydroxyalkanoates (PHA) and polylactic acid (PLA) are promising sustainable alternatives to replace synthetic plastic. This narrative review provides an overview of the real potential of PHA and PLA for cleaner production. For that purpose, the discussion considers an extensive literature that points out the environmental benefits about bioplastics and also the factors that limit their real sustainability. Through an analysis of future perspectives, a general contribution was offered by means of recommendations for a cleaner production of these bioplastics with the aim of promoting sustainable development. This set of factors can overcome the existing limitations, benefiting the environment, consumers and the market.

Graphic Abstract

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

Robeson L (2014) Historical perspective of advances in the science and technology of polymer blends. Polymers. https://doi.org/10.3390/polym6051251

Albuquerque PBS, Malafaia CB (2018) Perspectives on the production, structural characteristics and potential applications of bioplastics derived from polyhydroxyalkanoates. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2017.09.026

Philp JC, Bartsev A, Ritchie RJ, Baucher M-A, Guy K (2013) Bioplastics science from a policy vantage point. New Biotechnol. https://doi.org/10.1016/j.nbt.2012.11.021

Lim J, Hii S, Chee S, Wong CJ (2018) Sargassum siliquosum Agardh extract as potential material for synthesis of bioplastic film. J Appl Phycol. https://doi.org/10.1007/s10811-018-1603-2

Lithner D, Larsson Å, Dave G (2011) Environmental and health hazard ranking and assessment of plastic polymers based on chemical composition. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2011.04.038

Barnes DKA, Galgani F, Thompson RC, Barlaz M (2009) Accumulation and fragmentation of plastic debris in global environments. Philos Trans R Soc Lond Ser B. https://doi.org/10.1098/rstb.2008.0205

Gade R, Tulasi MS, Bhai VA (2013) Seaweeds: a novel biomaterial. Int J Pharm Pharm Sci 5:40–44

Harding KG, Dennis JS, Von Blottnitz H, Harrison STL (2007) Environmental analysis of plastic production processes: comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J Biotechnol. https://doi.org/10.1016/j.jbiotec.2007.02.012

Krueger MC, Harms H, Schlosser D (2015) Prospects for microbiological solutions to environmental pollution with plastics. Appl Microbiol Biotechnol. https://doi.org/10.1007/s00253-015-6879-4

Anjum A, Zuber M, Zia KM, Noreen A, Anjum MN, Tabasum S (2016) Microbial production of polyhydroxyalkanoates (PHAs) and its copolymers: a review of recent advancements. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2016.04.069

Kaza S, Yao LC, Bhada-Tata P, Van Woerden F (2018) What a waste 2.0: a global snapshot of solid waste management to 2050. Urban development. World Bank, Washington, DC

Machado ABS, Kloas W, Zarfl C, Hempel S, Rillig MC (2018) Microplastics as an emerging threat to terrestrial ecosystems. Glob Change Biol. https://doi.org/10.1111/gcb.14020

Lebreton L, Slat B, Ferrari F, Sainte-Rose B, Aitken J, Marthouse R, Hajbane S, Cunsolo S, Schwarz A, Levivier A, Noble K, Debeljak P, Maral H, Schoeneich-Argent R, Brambini R, Reisser J (2018) Evidence that the Great Pacific Garbage Patch is rapidly accumulating plastic. Sci Rep. https://doi.org/10.1038/s41598-018-22939-w

Tang Z, Zhang L, Huang Q, Yang Y, Nie Z, Cheng J, Yang J, Wang Y, Chai M (2015) Contamination and risk of heavy metals in soils and sediments from a typical plastic waste recycling area in North China. Ecotoxicol Environ Saf. https://doi.org/10.1016/j.ecoenv.2015.08.006

Waring RH, Harris RM, Mitchell SC (2018) Plastic contamination of the food chain: a threat to human health? Maturitas. https://doi.org/10.1016/j.maturitas.2018.06.010

Eriksen MK, Pivnenko K, Olsson ME, Astrup TF (2018) Contamination in plastic recycling: influence of metals on the quality of reprocessed plastic. J Waste Manag. https://doi.org/10.1016/j.wasman.2018.08.007

Wan Y, Wu C, Xue Q, Hui X (2019) Effects of plastic contamination on water evaporation and desiccation cracking in soil. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2018.11.123

Kühn S, Franeker JA, O’Donoghue AM, Swiers A, Starkenburg M, Werven B, Foekema E, Hermsen E, Egelkraut-Holtus M, Lindeboom H (2020) Details of plastic ingestion and fibre contamination in North Sea fishes. Environ Pollut. https://doi.org/10.1016/j.envpol.2019.113569

Shen M, Huang W, Chen M, Canção B, Zeng G, Zhang Y (2020) (Micro)plastic crisis: un-ignorable contribution to global greenhouse gas emissions and climate change. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.120138

Ruggero F, Gori R, Lubello C (2019) Methodologies to assess biodegradation of bioplastics during aerobic composting and anaerobic digestion: a review. Waste Manag Res. https://doi.org/10.1177/0734242X19854127

Zechendorf B (1999) Sustainable development: how can biotechnology contribute? Trends Biotechnol. https://doi.org/10.1016/S0167-7799(98)01297-9

Luken RA, Navratil J (2004) A programmatic review of UNIDO/UNEP national cleaner production centres. J Clean Prod. https://doi.org/10.1016/S0959-6526(03)00102-1

Giannetti BF, Agostinho F, Eras JJC, Yang Z, Almeida CMVB (2020) Cleaner production for achieving the sustainable development goals. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.122127

United Nations Environment Programme (2002) https://wedocs.unep.org/rest/bitstreams/982/retrieve. Accessed 23 Aug 2020

Yusup MZ, Mahmood WHW, Salleh MR, Rahman MN (2015) The implementation of cleaner production practices from Malaysian manufacturers’ perspectives. J Clean Prod. https://doi.org/10.1016/j.jclepro.2015.07.102

Elkington J (2007) Partnerships from cannibals with forks: the triple bottom line of 21st-century business. Environ Qual Manag. https://doi.org/10.1002/tqem.3310080106

Matos S, Silvestre BS (2013) Managing stakeholder relations when developing sustainable business models: the case of the Brazilian energy sector. J Clean Prod. https://doi.org/10.1016/j.jclepro.2012.04.023

Mores GV, Finocchio CPS, Barichello R, Pedrozo EA (2018) Sustainability and innovation in the Brazilian supply chain of green plastic. J Clean Prod. https://doi.org/10.1016/j.jclepro.2017.12.138

Ghazali I, Abdul-Rashid SH, Dawal SZM, Aoyama H, Tontowi AE, Sakundarini N (2017) Cultural influences on choosing green products: an empirical study in Malaysia. J Sustain Dev. https://doi.org/10.1002/sd.1685

Rahim R, Raman AAA (2017) Carbon dioxide emission reduction through cleaner production strategies in a recycled plastic resins producing plant. J Clean Prod. https://doi.org/10.1016/j.jclepro.2016.09.023

Calabrò PS, Grosso M (2018) Bioplastics and waste management. Waste Manag. https://doi.org/10.1016/j.wasman.2018.06.054

Yavagal PS, Kulkarni PA, Patil NM, Salimath NS, Patil AY, Savadi RS, Kotturshettar BB (2020) Cleaner production of edible straw as replacement for thermoset plastic. Mater Today. https://doi.org/10.1016/j.matpr.2020.02.667

Kreye O, Mutlu H, Meier MAR (2013) Sustainable routes to polyurethane precursors. Green Chem. https://doi.org/10.1039/c3gc40440d

Tsang YF, Kumar V, Samadar P, Yang Y, Lee J, Ok YS, Song H, Kim K-H, Kwon EE, Jeon YJ (2019) Production of bioplastic through food waste valorization. Environ Int. https://doi.org/10.1016/j.envint.2019.03.076

European Bioplastics (2020) https://docs.european-bioplastics.org/conference/Report_Bioplastics_Market_Data_2020_short_version.pdf. Accessed 22 Feb 2021

Institute for Bioplastics and Biocomposites (2015) Biopolymers facts and statistics. http://d-nb.info/1097422666/34. Acessed 20 Nov 2020

Fan YV, Chin HH, Klemes JJ, Varbanov PS, Liu X (2020) Optimisation and process design tools for cleaner production. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.119181

Fahim IS, Chbib H, Mahmoud HM (2019) The synthesis, production & economic feasibility of manufacturing PLA from agricultural waste. Sustain Chem Pharm. https://doi.org/10.1016/j.scp.2019.100142

Morali EK, Uzal N, Yetis U (2016) Ozonation pre and post-treatment of denim textile mill effluents: effect of cleaner production measures. J Clean Prod. https://doi.org/10.1016/j.jclepro.2016.07.059

Souza-Zomer TT, Magalhães L, Zancul E, Campos LMS, Cauchick-Miguel PA (2018) Cleaner production as an antecedent for circular economy paradigm shift at the micro-level: evidence from a home appliance manufacturer. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.03.006

Xiao X, Fu Z, Zhu Z, Zhang X (2019) Improved preservation process for table grapes cleaner production in cold chain. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.11.279

Jiao Y, Ji C, Yang S, Yang G, Su M, Fan H (2020) Home governments facilitate cleaner operations of outward foreign direct investment: a case study of a cleaner production partnership programme. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.121914

Ylias RA, Sapuan SM, Kadier A, Kalil MS, Ibrahim R, Atikah MSN, Nurazzi NM, Nazrin A, Lee CH, Nasmi MNFM, Sari H, Syafri E, Abral H, Jasmani L, Ibrahim MIJ (2020). In: Al-Oqla FM, Sapuan SM (eds) Advanced processing, properties, and applications of starch and other bio-based polymers. Elsevier, Amsterdam. https://doi.org/10.1016/B978-0-12-819661-8.00008-1

Elvers D, Song CH, Steinbüchel A, Leker J (2016) Technology trends in biodegradable polymers: evidence from patent analysis. Polym Rev. https://doi.org/10.1080/15583724.2015.1125918

Jariyasakoolroj P, Leelaphiwat P, Harnkarnsujarit N (2018) Advances in research and development of bioplastic for food packaging. J Sci Food Agric. https://doi.org/10.1002/jsfa.9497

Adeleye AT, Odoh CK, Enudi OC, Banjoko OO, Osiboye OO, Odediran ET, Louis H (2020) Sustainable synthesis and applications of polyhydroxyalkanoates (PHAs) from biomass. Process Biochem. https://doi.org/10.1016/j.procbio.2020.05.032

European Bioplastics (2021) https://www.european-bioplastics.org/bioplastics/. Accessed 22 Feb 2021

Bruder U (2015) Bioplastics and biocomposites. In: Bruder U (ed) User’s guide to plastic: a handbook for everyone. Carl Hanser Verlag GmbH & Co. KG, München

Lucas N, Bienaime C, Belloy C, Queneudec M, Silvestre F, Nava-Saucedo J-E (2008) Polymer biodegradation: mechanisms and estimation techniques—a review. Chemosphere. https://doi.org/10.1016/j.chemosphere.2008.06.064

Soroudi A, Jakubowicz I (2013) Recycling of bioplastics, their blends and biocomposites: a review. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2013.07.025

Larrañaga A, Lizundia E (2019) A review on the thermomechanical properties and biodegradation behaviour of polyesters. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2019.109296

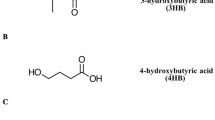

Steinbüchel A, Valentin HE (1995) Diversity of bacterial polyhydroxyalkanoic acids. FEMS Microbiol Lett. https://doi.org/10.1111/j.1574-6968.1995.tb07528.x

Sagong H, Son HF, Choi SY, Lee SY, Kim K (2018) Structural insights into polyhydroxyalkanoates biosynthesis. Trends Biochem Sci. https://doi.org/10.1016/j.tibs.2018.08.005

Titz M, Kettl K, Shahzad K, Koller M, Schnitzer H, Narodoslawsky M (2012) Process optimization for efficient biomediated PHA production from animal-based waste streams. Clean Technol Environ Policy. https://doi.org/10.1007/s10098-012-0464-7

Salazar A, Yepes M, Correa G, Mora A (2014) Polyhydroxyalkanoate production from unexplored sugar substrates. Dyna. https://doi.org/10.15446/dyna.v81n185.36844

Suwannasing W, Imai T, Kaewkannetra P (2015) Cost-effective defined medium for the production of polyhydroxyalkanoates using agricultural raw materials. Bioresour Technol. https://doi.org/10.1016/j.biortech.2015.06.087

Martín-Bufájer JM, López-Cuellar MDR, Vergara-Porras B (2016) Poly-[R-hydroxyalkanoates] production by cupriavidus necator ATCC 17699 using Mexican avocado (Persea americana) oil as carbon source. New Biotechnol. https://doi.org/10.1016/j.nbt.2015.10.050

Pérez-Arauz AO, Aguilar-Rabiela AE, Vargas-Torres A, Rodríguez-Hernández AI, Chavarría-Hernández N, Vergara-Porras B, López-Cuellar MR (2019) Production and characterization of biodegradable films of a novel polyhydroxyalkanoate (PHA) synthesized from peanut oil. Food Packag Shelf. https://doi.org/10.1016/j.fpsl.2019.01.001

Saratale RG, Cho S, Saratale GD, Kadam AA, Ghodak GS, Kumar M, Bharagava RN, Kumar G, Kim DS, Mulla SI, Shin HS (2021) A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour Technol. https://doi.org/10.1016/j.biortech.2021.124685

Ciesielski S, Możejko J, Pisutpaisal N (2015) Plant oils as promising substrates for polyhydroxyalkanoates production. J Clean Prod. https://doi.org/10.1016/j.jclepro.2014.09.040

Ng K-S, Ooi W-Y, Goh L-K, Shenbagarathai R, Sudesh K (2010) Evaluation of jatropha oil to produce poly(3-hydroxybutyrate) by Cupriavidus necator H16. Polym Degrad Stabil. https://doi.org/10.1016/j.polymdegradstab.2010.01.021

Krueger CL, Radetski C, Bendia AG, Oliveira IM, Castro-Silva MA, Rambo CR, Antonio RV, Lima A (2012) Bioconversion of cassava starch by-product into Bacillus and related bacteria polyhydroxyalkanoates. Electron J Biotechnol. https://doi.org/10.2225/vol15-issue3-fulltext-6

Gamal RF, Abdelhady HM, Khodair TA, El-Tayeb TS, Hassan EA, Aboutaleb KA (2013) Semi-scale production of PHAs from waste frying oil by Pseudomonas fluorescens S48. Braz J Microbiol. https://doi.org/10.1590/S1517-83822013000200034

Morais C, Freitas F, Cruz MV, Paiva A, Dionísio M, Reis MAM (2014) Conversion of fat-containing waste from the margarine manufacturing process into bacterial polyhydroxyalkanoates. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2014.04.044

Obruca S, Benesova P, Petrik S, Oborna J, Prikryl R, Marova I (2014) Production of polyhydroxyalkanoates using hydrolysate of spent coffee grounds. Process Biochem. https://doi.org/10.1016/j.procbio.2014.05.013

Haas C, Steinwandter V, Apodaca ED, Madurga BM, Smerilli M, Dietrich T, Neureiter M (2015) Production of PHB from chicory roots—comparison of three Cupriavidus necator strains. Chem Biochem Eng Q. https://doi.org/10.15255/CABEQ.2014.2250

Yousuf RG, Winterburn JB (2017) Waste date seed oil extract as an alternative feedstock for poly(3-hydroxybutyrate) synthesis. Biochem Eng J. https://doi.org/10.1016/j.bej.2017.08.007

Urbina L, Wongsirichot P, Corcuera MA, Gabilondo N, Eceiza A, Winterburn J, Rategi A (2018) Application of cider by-products for medium chain length polyhydroxyalkanoate production by Pseudomonas putida KT2440. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2018.08.020

Raho S, Carofiglio VE, Montemurro M, Miceli V, Centrone D, Stufano P, Schioppa M, Pontonio E, Rizzello CG (2020) Production of the polyhydroxyalkanoate PHBV from ricotta cheese exhausted whey by Haloferax mediterranei fermentation. Foods. https://doi.org/10.3390/foods9101459

Silva LF, Gomez JGC, Rocha RCS, Taciro MK, Pradella JGC (2007) Biotechnological production of polyhydroxyalkanoates in Brazil for biodegradable polymers. Quim Nova. https://doi.org/10.1590/S0100-40422007000700040

Rodriguez-Perez S, Serrano A, Pantión AA, Alonso-Fariñas B (2018) Challenges of scaling-up PHA production from waste streams: a review. J Environ Manag. https://doi.org/10.1016/j.jenvman.2017.09.083

Acosta-Cárdenas A, Alcaraz-Zapata W, Cardona-Betancur M (2018) Sugarcane molasses and vinasse as a substrate for polyhydroxyalkanoates (PHA) production. Dyna. https://doi.org/10.15446/dyna.v85n206.68279

Albuquerque MGE, Eiroa M, Torres C, Nunes BR, Reis MAM (2007) Strategies for the development of a side stream process for polyhydroxyalkanoate (PHA) production from sugar cane molasses. J Biotechnol. https://doi.org/10.1016/j.jbiotec.2007.05.011

Gonzalez-Lopez J, Pozo C, Martinez-Toledo MV, Rodelas B, Salmeron V (1996) Production of polyhydroxyalkanoates by Azotobacter chroococcum H23 in wastewater from olive oil mills (alpechin). Int Biodeterior Biodegrad. https://doi.org/10.1016/S0964-8305(96)00060-1

Yan S, Bala Subramanian S, Tyagi RD, Surampalli RY (2008) Bioplastics from activated sludge treating pulp and paper wastewater. J Biotechnol. https://doi.org/10.1016/j.jbiotec.2008.07.060

Mumtaz T, Yahaya NA, Abd-Aziz S, Abdul Rahman NA, Yee PL, Shirai Y, Hassan MA (2010) Turning waste to wealth-biodegradable plastics polyhydroxyalkanoates from palm oil mill effluent: a Malaysian perspective. J Clean Prod. https://doi.org/10.1016/j.jclepro.2010.05.016

Ben M, Mato T, Lopez A, Vila M, Kennes C, Veiga MC (2011) Bioplastic production using wood mill effluents as feedstock. Water Sci Technol. https://doi.org/10.2166/wst.2011.358

Gangurde NS, Sayyed RZ, Kiran S, Gulati A (2013) Development of eco-friendly bioplastic like PHB by distillery effluent microorganisms. Environ Sci Pollut R. https://doi.org/10.1007/s11356-012-1021-y

Mayeli N, Motamedi H, Heidarizadeh F (2015) Production of polyhydroxybutyrate by Bacillus axaraqunsis BIPC01 using petrochemical wastewater as carbon source. Braz Arch Biol Technol. https://doi.org/10.1590/S1516-8913201500048

Mohapatra S, Mohanta PR, Sarkar B, Daware A, Kumar C, Samantaray DP (2017) Production of polyhydroxyalkanoates (PHAs) by Bacillus strain isolated from waste water and its biochemical characterization. Proc Natl A Sci India B. https://doi.org/10.1016/10.1007/s40011-015-0626-6

Lemechko P, Le Fellic M, Bruzaud S (2019) Production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) using agro-industrial effluents with tunable proportion of 3-hydroxyvalerate monomer units. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2019.01.170

Amulya K, Reddy MV, Rohit MV, Mohan SV (2016) Wastewater as renewable feedstock for bioplastics production: understanding the role of reactor microenvironment and system pH. J Clean Prod. https://doi.org/10.1016/j.jclepro.2015.08.009

Liu H, Hall PV, Darby JL, Coats EL, Green PG, Thompson DE, Loge FJ (2008) Production of polyhydroxyalkanoate during treatment of tomato cannery wastewater. Water Environ Res. https://doi.org/10.2175/106143007X221535

Jiang Y, Marang L, Tamis J, Van Loosdrecht MCM, Dijkman H, Kleerebezem R (2012) Waste to resource: converting paper mill wastewater to bioplastic. Water Res. https://doi.org/10.1016/j.watres.2012.07.028

Cerrone F, Davis R, Kenny ST, Woods T, O’Donovan A, Gupta VK, Tuohy M, Babu RP, O’Kiely P, O’Connor K (2015) Use of a mannitol rich ensiled grass press juice (EGPJ) as a sole carbon source for polyhydroxyalkanoates (PHAs) production through high cell density cultivation. Bioresour Technol. https://doi.org/10.1016/j.biortech.2015.04.128

Elain A, Le Grand A, Corre Y-M, Le Fellic M, Hachet N, Le Tilly V, Loulergue P, Audic J-L, Bruzaud S (2016) Valorisation of local agro-industrial processing waters as growth media for polyhydroxyalkanoates (PHA) production. Ind Crop Prod. https://doi.org/10.1016/j.indcrop.2015.10.052

Venkatesan L, Anil S, Kim S, Shim MS (2016) Seaweed polysaccharide-based nanoparticles: preparation and applications for drug delivery. Polymers. https://doi.org/10.3390/polym8020030

Karan H, Funk C, Grabert M, Oey M, Hankamer B (2019) Green bioplastics as part of a circular bioeconomy. Trends Plant Sci. https://doi.org/10.1016/j.tplants.2018.11.010

Singh AK, Sharma L, Mallick N, Mala J (2017) Progress and challenges in producing polyhydroxyalkanoate biopolymers from cyanobacteria. J Appl Phycol. https://doi.org/10.1016/10.1007/s10811-016-1006-1

Arias DM, Uggetti E, García-Galán MJ, García J (2018) Production of polyhydroxybutyrates and carbohydrates in a mixed cyanobacterial culture: effect of nutrients limitation and photoperiods. New Biotechnol. https://doi.org/10.1016/j.nbt.2018.01.001

Monshupanee T, Nimdach P, Incharoensakdi A (2016) Two-stage (photoautotrophy and heterotrophy) cultivation enables efficient production of bioplastic poly-3-hydroxybutyrate in auto-sedimenting cyanobacterium. Sci Rep. https://doi.org/10.1038/srep37121

Weiss TL, Young EJ, Ducat DC (2017) A synthetic, light-driven consortium of cyanobacteria and heterotrophic bacteria enables stable polyhydroxybutyrate production. Metab Eng. https://doi.org/10.1016/j.ymben.2017.10.009

Cesário MT, da Fonseca MMR, Marques MM, de Almeida MCMD (2018) Marine algal carbohydrates as carbon sources for the production of biochemicals and biomaterials. Biotechnol Adv. https://doi.org/10.1016/j.biotechadv.2018.02.006

Costa SS, Miranda AL, Andrade BB, Assis DDJ, Souza CO, de Morais MG, Costa JAV, Druzian JI (2018) Influence of nitrogen on growth, biomass composition, production, and properties of polyhydroxyalkanoates (PHAs) by microalgae. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2018.05.064

Ghosh S, Gnaim R, Greiserman S, Fadeev L, Gozin M, Golberg A (2019) Macroalgal biomass subcritical hydrolysates for the production of polyhydroxyalkanoate (PHA) by Haloferax mediterranei. Bioresour Technol. https://doi.org/10.1016/j.biortech.2018.09.108

Zhang C, Show P-L, Ho S-H (2019) Progress and perspective on algal plastics: a critical review. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.121700

Ecker JV, Burzic I, Haider A, Hild S, Rennhofer H (2019) Improving the impact strength of PLA and its blends with PHA in fused layer modelling. Polym Test. https://doi.org/10.1016/j.polymertesting.2019.105929

Chandra R, Rustgi R (1998) Biodegradable polymers. Prog Polym Sci. https://doi.org/10.1016/S0079-6700(97)00039-7

Babu RP, O’Connor K, Seeram R (2013) Current progress on bio-based polymers and their future trends. Prog Biomater. https://doi.org/10.1186/2194-0517-2-8

López-Gómez JP, Pérez-Rivero C, Venus J (2020) Valorisation of solid biowastes: the lactic acid alternative. Process Biochem. https://doi.org/10.1016/j.procbio.2020.08.029

Oh H, Wee Y-J, Yun J-S, Ho Han S, Jung S, Ryu H-W (2005) Lactic acid production from agricultural resources as cheap raw materials. Bioresour Technol. https://doi.org/10.1016/j.biortech.2004.11.020

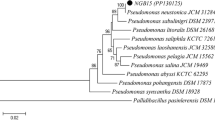

Ong YY, Tan WS, Rosfarizan M, Chan ES, Tey BT (2012) Isolation and identification of lactic acid bacteria from fermented red dragon fruit juices. J Food Sci. https://doi.org/10.1111/j.1750-3841.2012.02894.x

Silveira MS, Fontes CPML, Guilherme AA, Fernades FAN, Rodrigues S (2012) Cashew apple juice as substrate for lactic acid production. Food Bioprocess Technol. https://doi.org/10.1007/s11947-010-0382-9

Okano K, Hama S, Kihara M, Noda H, Tanaka T, Kondo A (2017) Production of optically pure d-lactic acid from brown rice using metabolically engineered Lactobacillus plantarum. Appl Microbiol Biotechnol. https://doi.org/10.1007/s00253-016-7976-8

Kasirajan S, Umapathy D, Chandrasekar C, Aafrin V, Janitapeter M, Udhyasooriyan L, Packirisamy ASB, Muthusamy S (2019) Preparation of poly (lactic acid) from Prosopis juliflora and incorporation of chitosan for packaging applications. J Biosci Bioeng. https://doi.org/10.1016/j.jbiosc.2019.02.013

Cui F, Li Y, Wan C (2011) Lactic acid production from corn stover using mixed cultures of Lactobacillus rhamnosus and Lactobacillus brevis. Bioresour Technol. https://doi.org/10.1016/j.biortech.2010.09.063

Nguyen CM, Kim J-S, Nguyen TN, Kim SK, Choi GJ, Choi YH, Jang KS, Kim J-C (2013) Production of l- and d-lactic acid from waste Curcuma longa biomass through simultaneous saccharification and cofermentation. Bioresour Technol. https://doi.org/10.1016/j.biortech.2013.07.035

Xu K, Xu P (2014) Efficient production of l-lactic acid using co-feeding strategy based on cane molasses/glucose carbon sources. Bioresour Technol. https://doi.org/10.1016/j.biortech.2013.11.057

Pagana I, Morawicki R, Hager TJ (2014) Lactic acid production using waste generated from sweet potato processing. Int J Food Sci Technol. https://doi.org/10.1111/ijfs.12347

Zheng Y, Wang Y, Zhang J, Pan J (2016) Using tobacco waste extract in pre-culture medium to improve xylose utilization for l-lactic acid production from cellulosic waste by Rhizopus oryzae. Bioresour Technol. https://doi.org/10.1016/j.biortech.2016.06.071

Peinemann JC, Demichelis F, Fiore S, Pleissner D (2019) Techno-economic assessment of non-sterile batch and continuous production of lactic acid from food waste. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.121631

Torre I, Acedos MG, Ladero M, Santos VE (2019) On the use of resting L. delbrueckii spp. delbrueckii cells for D-lactic acid production from orange peel wastes hydrolysates. Biochem Eng J. https://doi.org/10.1016/j.bej.2019.02.012

Alexandri M, Blanco-Catalá J, Schneider R, Turon X, Venus J (2020) High L(+)-lactic acid productivity in continuous fermentations using bakery waste and lucerne green juice as renewable substrates. Bioresour Technol. https://doi.org/10.1016/j.biortech.2020.123949

Kanpiengjai A, Lumyong S, Pathom-Aree W, Khanongnuch C (2014) Starchy effluent from rice noodle manufacturing process as feasible substrate for direct lactic acid production by Lactobacillus plantarum S21. J Korean Soc Appl Biol Chem. https://doi.org/10.1007/s13765-013-4311-2

Li J, Zhang W, Li X, Ye T, Gan Y, Zhang A, Chen H, Xue G, Liu Y (2018) Production of lactic acid from thermal pretreated food waste through the fermentation of waste activated sludge: effects of substrate and thermal pretreatment temperature. Bioresour Technol. https://doi.org/10.1016/j.biortech.2017.09.186

Pinho CLC, Oliveira CES, Coimbra JC, Cotrim WS (2019) Production of lactic acid in a medium based on food industry effluents using an immobilized mixed dairy culture. Braz J Food Technol. https://doi.org/10.1590/1981-6723.10018

Nair NR, Nampoothiri KM, Banarjee R, Reddy G (2016) Simultaneous saccharification and fermentation (SSF) of jackfruit seed powder (JFSP) to l-lactic acid and to polylactide polymer. Bioresour Technol. https://doi.org/10.1016/j.biortech.2016.03.020

Zhang C, Wang C, Cao G, Wang D, Ho S (2020) A sustainable solution to plastics pollution: an eco-friendly bioplastic film production from high-salt contained Spirulina sp. residues. J Clean Prod. https://doi.org/10.1016/j.jhazmat.2019.121773

Spierling S, Knüpffer E, Behnsen H, Mudersbach M, Krieg H, Springer S, Albrecht S, Hermann C, Endres H (2018) Bio-based plastics: a review of environmental, social and economic impact assessments. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.03.014

Brockhaus S, Petersen M, Kersten W (2016) A crossroads for bioplastics: exploring product developers’ challenges to move beyond petroleum-based plastics. J Clean Prod. https://doi.org/10.1016/j.jclepro.2016.04.003

Walker S, Rothman R (2020) Life cycle assessment of bio-based and fossil-based plastic: a review. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.121158

Yadav B, Pandey A, Kumar LR, Tyagi RD (2020) Bioconversion of waste (water)/residues to bioplastics: a circular bioeconomy approach. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.122584

Iles A, Martin AN (2013) Expanding bioplastics production: sustainable business innovation in the chemical industry. J Clean Prod. https://doi.org/10.1016/j.jclepro.2012.05.008

Kabir E, Kaur R, Lee J, Kim K, Kwon EE (2020) Prospects of biopolymer technology as an alternative option for non-degradable plastics and sustainable management of plastic wastes. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.120536

Koller M, Braunegg G (2018) Advanced approaches to produce polyhydroxyalkanoate (PHA) biopolyesters in a sustainable and economic fashion. EuroBiotech J. https://doi.org/10.2478/ebtj-2018-0013

Kumar M, Rathour R, Singh R, Sun Y, Pandey A, Gnansounou E, Lin KA, Tsang DCW, Thakur IS (2020) Bacterial polyhydroxyalkanoates: opportunities, challenges, and prospects. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.121500

Alcântara JMC, Distante F, Stort G, Moscatelli D, Morbidelli M, Sponchioni M (2020) Current trends in the production of biodegradable bioplastics: the case of polyhydroxyalkanoates. Biotechnol Adv. https://doi.org/10.1016/j.biotechadv.2020.107582

Mannina G, Prsti D, Montiel-Jarillo G, Carrera J, Suárez-Ojeda ME (2020) Recovery of polyhydroxyalkanoates (PHAs) from wastewater: a review. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.122478

Koller M, Maršálek L, de Sousa Dias MM, Braunegg G (2017) Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. New Biotechnol. https://doi.org/10.1016/j.nbt.2016.05.001

Biocycle (2021) http://www.biocycle.com.br/fluxograma.htm. Accessed 14 Feb 2021

Li M, Wilkins MR (2020) Recent advances in polyhydroxyalkanoate production: feedstocks, strains and process developments. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2020.04.082

Tang X, Chen EYX (2019) Toward infinitely recyclable plastics derived from renewable cyclic esters. Chem. https://doi.org/10.1016/j.chempr.2018.10.011

Mohapatra S, Pattnaik S, Maity S, Mohapatra S, Sharma S, Akhtar J, Pati S, Samantaray DP, Varma A (2020) Comparative analysis of PHAs production by Bacillus megaterium OUAT 016 under submerged and solid-state fermentation. Saudi J Biol Sci. https://doi.org/10.1016/j.sjbs.2020.02.001

Yazid NA, Barrena R, Komilis D, Sánchez A (2017) Solid-state fermentation as a novel paradigm for organic waste valorization: a review. Sustainability. https://doi.org/10.3390/su9020224

Chee J-Y, Yoga S, Sudesh K (2010) Bacterially produced polyhydroxyalkanoate (PHA): converting renewable resources into bioplastics. In: Méndez-Vilas A (ed) Current research, technology and education topics in applied microbiology and microbial biotechnology. Formatex Research Center, Badajoz

Bai H, Deng S, Bai D, Zhang Q, Fu Q (2017) Recent advances in processing of stereocomplex-type polylactide. Macromol Rapid Commun. https://doi.org/10.1002/marc.201700454

Jem KJ, Tan B (2020) The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv Ind Eng Polym Res. https://doi.org/10.1016/j.aiepr.2020.01.002

Jem KJ, Pol JF, Vos S (2010) Microbial lactic acid, its polymer poly (lactic acid), and their industrial applications. In: Chen GG-Q (ed) Plastics from bacteria. Springer, Berlin. https://doi.org/10.1007/978-3-642-03287-5_13

Huang Y, Xiao C, Huang Q, Liu H, Zhao J (2021) Progress on polymeric hollow fiber membrane preparation technique from the perspective of green and sustainable development. Chem Eng J. https://doi.org/10.1016/j.cej.2020.126295

Álvarez-Chávez CR, Edwards S, Moure-Eraso R, Geiser K (2012) Sustainability of bio-based plastics: general comparative analysis and recommendations for improvement. J Clean Prod. https://doi.org/10.1016/j.jclepro.2011.10.003

Oliveira RA, Komesu A, Rossell CEV, Maciel Filho R (2018) Challenges and opportunities in lactic acid bioprocess design: from economic to production aspects. Biochem Eng J. https://doi.org/10.1016/j.bej.2018.03.003

Djukić-Vuković A, Mladenović D, Ivanović J, Pejin J, Mojović L (2019) Towards sustainability of lactic acid and poly-lactic acid polymers production. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2019.03.050

Fabra MJ, Martínez-Sanz M, Gómez-Mascaraque LG, Coll-Marqués JM, Martínez JC, López-Rubio A (2017) Development and characterization of hybrid corn starch-microalgae films: effect of ultrasound pre-treatment on structural, barrier and mechanical performance. Algal Res. https://doi.org/10.1016/j.algal.2017.10.010

Dietrich K, Dumont M-J, Del Rio LF, Orsat V (2017) Producing PHAs in the bioeconomy: towards a sustainable bioplastic. Sustain Prod Consum. https://doi.org/10.1016/j.spc.2016.09.001

Mathiot C, Ponge P, Gallard B, Sassi J-F, Delrue F, Le Moigne N (2019) Microalgae starch-based bioplastics: screening of ten strains and plasticization of unfractionated microalgae by extrusion. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2018.12.057

Price S, Kuzhiumparambil U, Pernice M, Ralph PJ (2020) Cyanobacterial polyhydroxybutyrate for sustainable bioplastic production: critical review and perspectives. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2020.104007

Arias DM, García J, Uggetti E (2020) Production of polymers by cyanobacteria grown in wastewater: current status, challenges and future perspectives. New Biotechnol. https://doi.org/10.1016/j.nbt.2019.09.001

Bussa M, Eisen A, Zollfrank C, Röder H (2019) Life cycle assessment of microalgae products: state of the art and their potential for the production of polylactid acid. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.12.048

Rossi V, Cleeve-Edwards N, Lundquist L, Schenker U, Dubois C, Humbert S, Jolliet O (2015) Life cycle assessment of end-of-life options for two biodegradable packaging materials: sound application of the European waste hierarchy. J Clean Prod. https://doi.org/10.1016/j.jclepro.2014.08.049

Kakadellis S, Harris ZM (2020) Don’t scrap the waste: the need for broader system boundaries in bioplastic food packaging life-cycle assessment: a critical review. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.122831

Kale G, Kijchavengkul T, Auras R, Rubino M, Selke SE, Singh SP (2007) Compostability of bioplastic packaging materials: an overview. Macromol Biosci. https://doi.org/10.1002/mabi.200600168

Narancic T, Verstichel S, Chaganti SR, Morales-Gamez L, Kenny ST, Wilde B, Babu Padamati R, O’connor KE (2018) Biodegradable plastic blends create new possibilities for end-of-life management of plastics but they are not a panacea for plastic pollution. Environ Sci Technol. https://doi.org/10.1021/acs.est.8b02963

Boyandin AN, Prudnikova SV, Karpov VA, Ivonin VN, Dỗ NL, Nguyễn TH, Lê TMH, Filichev NL, Levin AL, Filipenko ML, Volova TG, Gitelson II (2013) Microbial degradation of polyhydroxyalkanoates in tropical soils. Int Biodeterior Biodegrad. https://doi.org/10.1016/j.ibiod.2013.04.014

Karamanlioglu M, Preziosi R, Robson GD (2017) Abiotic and biotic environmental degradation of the bioplastic polymer poly (lactic acid): a review. Polym Degrad Stabil. https://doi.org/10.1016/j.polymdegradstab.2017.01.009

Haugaard VK, Udsen A-M, Mortensen G, Høegh L, Peterson K, Monahan F (2001) Potential food applications of biobased materials: an EU-concerted action project. Starch. https://doi.org/10.1002/1521-379X(200105)53:5%3c189::AID-STAR189%3e3.0.CO;2-3

Lagaron JM, Lopez-Rubio A (2011) Nanotechnology for bioplastics: opportunities, challenges and strategies. Trends Food Sci Technol. https://doi.org/10.1016/j.tifs.2011.01.007

Burzic I, Pretschuh C, Kaineder D, Eder G, Smilek J, Másilko J, Kateryna W (2019) Impact modification of PLA using biobased biodegradable PHA biopolymers. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2019.01.060

Rasal RM, Janorkar AV, Hirt DE (2010) Poly (lactic acid) modifications. Prog Polym Sci. https://doi.org/10.1016/j.progpolymsci.2009.12.003

Ma P, Hristova-Bogaerds DG, Goossens JGP, Spoelstra AB, Zhang Y, Lemstra PJ (2012) Toughening of poly(lactic acid) by ethylene-co-vinyl acetate copolymer with different vinyl acetate contents. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2011.10.015

Castro-Aguirre E, Ligueigue-Franco F, Samsudin H, Fang X, Auras R (2016) Poly(lactic acid)—mass production, processing, industrial applications, and end of life. Adv Drug Deliv Rev. https://doi.org/10.1016/j.addr.2016.03.010

Song R, Murphy M, Li CS, Ting K, Soo C, Zheng Z (2018) Current development of biodegradable polymeric materials for biomedical applications. Drug Des Dev Ther. https://doi.org/10.2147/DDDT.S165440

Naderi P, Zarei M, Karbasi S, Salehi H (2020) Evaluation of the effects of keratin on physical, mechanical and biological properties of poly (3-hydroxybutyrate) electrospun scaffold: potential application in bone tissue engineering. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2020.109502

Mowafi S, El-Sayed H, Taleb MA (2018) Utilization of proteinic biopolymers: current status and future prospects. J Text Color Polym Sci. https://doi.org/10.21608/JTCPS.2018.5007.1002

Skrabania L (2018) https://en.reset.org/blog/algix-biodegradable-3d-printing-powered-algae-07092018. Accessed 19 Aug 2020

Jerez A, Partal P, Martínez I, Gallegos C, Guerrero A (2007) Protein-based bioplastics: effect of thermo-mechanical processing. Rheol Acta. https://doi.org/10.1007/s00397-007-0165-z

Hatti-Kaul R, Nilsson LJ, Zhang B, Rehnberg N, Lundmark S (2020) Designing biobased recyclable polymers for plastics. Trends Biotechnol. https://doi.org/10.1016/j.tibtech.2019.04.011

Dael MV, Márquez N, Reumerman P, Pelkmans L, Kuppens T, Passel SV (2014) Development and techno-economic evaluation of a biorefinery based on biomass (waste) streams—case study in the Netherlands. Biofpr. https://doi.org/10.1002/bbb.1460

Jeong HJ, Ko Y (2016) Configuring an alliance portfolio for eco-friendly innovation in the car industry: Hyundai and Toyota. J Open Innov. https://doi.org/10.1186/s40852-016-0050-z

Gyarmath B, Pukánszky B (2017) Natural polymers, bio-inspired and smart macromolecular materials. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2019.08.003

Al-Battashi HS, Annamalai N, Sivakumar N, Al-Bahry S, Tripathi BN, Nguyen QD, Gupta VK (2019) Lignocellulosic biomass (LCB): a potential alternative biorefinery feedstock for polyhydroxyalkanoates production. Rev Environ Sci Biotechnol. https://doi.org/10.1007/s11157-018-09488-4

Sabapathy PC, Devaraj S, Meixner K, Anburajan P, Kathirvel P, Ravikumar Y, Zabed HM, Qi X (2020) Recent developments in polyhydroxyalkanoates (PHAs) production: a review. Bioresour Technol. https://doi.org/10.1016/j.biortech.2020.123132

Emadian SM, Onay TT, Demirel B (2017) Biodegradation of bioplastics in natural environments. J Waste Manag. https://doi.org/10.1016/j.wasman.2016.10.006

Rameshkumar S, Shaiju P, O’connor KE, Babu R (2020) Bio-based and biodegradable polymers—state-of-the-art, challenges and emerging trends. Curr Opin Green Sustain Chem. https://doi.org/10.1016/j.cogsc.2019.12.005

Krausmann F, Gingrich S, Eisenmenger N, Erb K, Haberl H, Fischer-Kowalski M (2009) Growth in global materials use, GDP and population during the 20th century. Ecol Econ. https://doi.org/10.1016/j.ecolecon.2009.05.007

Cordier M, Uehara T (2019) How much innovation is needed to protect the ocean from plastic contamination? Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2019.03.258

Rochman CM (2016) Strategies for reducing ocean plastic debris should be diverse and guided by science. Environ Res Lett. https://doi.org/10.1088/1748-9326/11/4/041001

Subramanian N, Gunasekaran A (2015) Cleaner supply-chain management practices for twenty-first-century organizational competitiveness: practice-performance framework and research propositions. Int J Prod Econ. https://doi.org/10.1016/j.ijpe.2014.12.002

Zhang P, Duan N, Dan Z, Shi F, Wang H (2018) An understandable and practicable cleaner production assessment model. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.03.284

Schnurr REJ, Alboiu V, Chaudhary M, Corbett RA, Quanz ME, Sankar K, Srain HS, Thavarajah V, Xanthos D, Walker TR (2018) Reducing marine pollution from single-use plastics (SUPs): a review. Mar Pollut Bull. https://doi.org/10.1016/j.marpolbul.2018.10.001

European Bioplastics (2021) https://www.european-bioplastics.org/policy/bioeconomy/. Accessed 22 Feb 2021

Oliveira JA, Oliveira OJ, Ometto AR, Ferraudo AS, Salgado MH (2016) Environmental management system ISO 14001 factors for promoting the adoption of cleaner production practices. J Clean Prod. https://doi.org/10.1016/j.jclepro.2016.06.013

Oliveira JA, Silva DAL, Ganga GMD, Godinho Filho M, Ferreira AA, Esposto KF, Ometto AR (2019) Cleaner production practices, motivators and performance in the Brazilian industrial companies. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.05.013

Schnitzer H, Ulgiati S (2007) Less bad is not good enough: approaching zero emissions techniques and systems. J Clean Prod. https://doi.org/10.1016/j.jclepro.2006.08.001

Markarian J (2008) Biopolymers present new market opportunities for additives in packaging. Plast Addit Compd. https://doi.org/10.1016/S1464-391X(08)70091-6

Briassoulis D, Giannoulis A (2018) Evaluation of the functionality of bio-based food packaging films. Polym Test. https://doi.org/10.1016/j.polymertesting.2018.05.003

Vinod A, Sanjay MR, Suchar S, Jyotishkumar P (2020) Renewable and sustainable biobased materials: an assessment on biofibers, biofilms, biopolymers and biocomposites. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.120978

Acknowledgements

The authors gratefully acknowledge the financial support of CNPq (Brazil’s National Council for Scientific and Technological Development), through Grant number 304675/2016-4.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical Approval

I would like to confirm that the manuscript has not been published previously by any of the authors and/or is not under consideration for publication in another journal at the time of submission.

Consent to Participate

I would like to confirm that all authors have seen and approved the submission of the manuscript concerned.

Consent for Publication

I would like to confirm that all authors agree with the publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Castro, T.R., de Macedo, D.C., de Genaro Chiroli, D.M. et al. The Potential of Cleaner Fermentation Processes for Bioplastic Production: A Narrative Review of Polyhydroxyalkanoates (PHA) and Polylactic Acid (PLA). J Polym Environ 30, 810–832 (2022). https://doi.org/10.1007/s10924-021-02241-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02241-z