Abstract

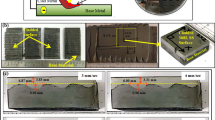

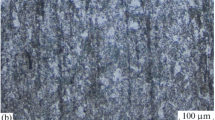

This study deals with the performance of a 1 mm-thick wear resistance cladding layer of composite metal powder of 110~160 μm-sized STL-1(Co-Cr alloy) and 100 μm-sized MBF-15 (Ni based brazing alloy) applied by the resistance welding method to clad 1.9 mm-thick mild steel plate. Two metal powders were prepared as the cladding materials, in the ratio of two to one by weight. We studied the microstructures and results of EPMA of cladding layers to obtain the most suitable joint conditions. Also, bending and abrasion tests were performed to evaluate the bond-ability with the substrate and the wear behaviour of the cladding layer. The main results obtained are as follows: The wear resistance cladding layer had sound microstructures when it had been applied under the following welding conditions: welding current higher than 2.1 kA, welding speed of 1.0 m/min, and electrode force less than 392 N. In spite of cracks occurring in the cladding layer after the bending test, the cladding layer, applied under almost all welding conditions, was not separated from the substrate. We obtained the wear behaviour of the mild steel, 16.833 mg/min-wear loss and 0.046 mm/min-abrasion depth. The characteristics of the cladding layer, which had been applied with welding conditions — welding current of 2.5 kA, welding speed of 1.0 m/min, and electrode force of 196 N, had a satisfactory wear resistance behaviour of 15.726 mg/min-wear loss and 0.043 mm/min-abrasion depth.

Similar content being viewed by others

References

Satou. Kenji: Wear phenomenon of metals and measures about its (in Japanese,) 1965, 1–3.

Shin J.C. et al.: Effect of molybdenum on the microstructure and wear resistance of cobalt-base Stellite hardfacing alloys, Surface and Coatings 166, 2003, 117–126.

Atony K.C.: Wear resistant cobalt-base alloys, J. Metal, 1983.

Atony K.C. et al.: Hardfacing, vol. 6, ASM, Handbook, 1983, pp. 771.

O’Brien R.L.: Editor Welding handbook vol.2 welding processes, 1991, pp. 532–559.

Japan amorphous metal corporate, Ni base Brazing Foils, pp. 3–5.

Taylor Lyman, A.B.: Metal handbook, Ninth edition Powder Metallurgy, 1984, pp. 144–146.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, J.W., Nishio, K., Katoh, M. et al. The Performance of a Wear Resistance Cladding Layer on a Mild Steel Plate by Electric Resistance Welding. Weld World 49, 94–101 (2005). https://doi.org/10.1007/BF03266493

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266493