Abstract

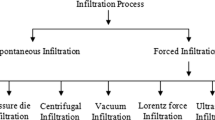

Pressure infiltration of liquid metal is one of the most important processing routes for the production of aluminum-matrix composites having a self-supporting reinforcement phase. This article briefly examines the physical phenomena governing infiltration processes, to present practical guidelines derived from their analysis for optimization of the process and the materials produced. Engineering aspects that are pertinent to infiltration techniques, including preform preparation, process configurations, flow control, and innovative processes, are summarized.

Similar content being viewed by others

References

V.J. Michaud, Fundamentals of Metal Matrix Composites, ed. S. Suresh, A. Mortensen, and A. Needleman (Stoneham, MA: Butterworth-Heinemann, 1992).

R. Elliott, Eutectic Solidification Proassing: Crystalline and Glassy Alloys, (London: Butterworths, 1983), chapter 7.

A.W. Urquhart, “Novel Reinforced Ceramics and Metals: A Review of Lanxide’s Composite Technologies,” Mater. Sci. & Eng., A144 (1991), pp. 75–82.

A. Mortensen and I. Jin, “Solidification Processing of Metal Matrix Composites,” Int. Mater. Rev., 37 (1992), pp. 101–128.

T. Donomoto et al., “Ceramic Fiber Reinforced Piston for High Performance Diesel Engines,” SAE Technical Paper Series (Warrendale, PA: SAE, 1983).

M. Ebisawa et al., “Production Process of Metal Matrix Composite (MMC) Engine Block,” SAE Technical Paper Series (Warrendale, PA: SAE, 25 February 1991).

M.K. Premkumar, W.H. Hunt, and R.R. Sawtell, “Aluminum Composite Materials for Multichip Modules,” JOM, 44(7) (1992), pp. 24–28.

F.V. Lenel, Powder Metallurgy, (Princeton, NJ: MPIF, 1980), pp. 588.

K.A. Semlak and F.N. Rhines, “The Rate of Infiltration of Metals,” Trans. Met. Soc. AIME, 212 (1998), pp. 325–331.

A.J. Shaler, “Theoretical ASpects of the Infiltration of Powder Metallurgy Products,” Int. J. Powder Metall., 1 (1965), pp. 3–14.

H. Fukunaga and M. Kuriyama, “Experimental Srudy on the Fabrication of Fiber Reinforced Aluminium by Squeeze Casting,” Bull. Jpn. Soc. Mech. Engrs., 25 (1982), pp. 842–847.

H. Fukunaga and T. Ohde, “Squeeze Casting of Silicon Carbide Fiber Reinforced Aluminum,” Fourth International Conference on Composite Materials, ICCM-IV, ed. T. Hayashi, K. Kawata, and S. Umakawa (Tokyo: Jpn. Soc. Compo Mater., 1982), pp. 1443–1450.

H. Fukunaga, S. Komatsu, and Y. Kanoh, “The Production-Scale Squeeze Casting of Devitroceramic Fiber Reinforced Aluminum and its Mechanical Properties,” Bull. Jpn. Soc. Mech. Engrs., 26 (1983), pp. 1814–1819.

S. Nagata and K. Matsuda, “Effect of Some Factors on the Critical Preheating Temperature of Particles in Producing Metal-Particle Composites by Pressure Casting,” IMONO, Trans. Jpn. Foundrymen’s Soc., 53 (1981), pp. 300–304.

H. Fukunaga and K. Goda, “Fabrication of Fiber Reinforced Metal by Squeeze Casting (Pressurized Infiltration Process of Molten Aluminum to Continuous Glass Fiber Bundle),” Bull. Jpn. Soc. Mech. Engrs., 27 (1984), pp. 1245–1250.

H. Fukunaga and K. Goda, “Formation and Role of the Solidified Layer on a Fiber during the Fabrication of Fiber Reinforced Metal by the Liquid Process,” J. Jpn. Inst. Met., 49 (1985), pp. 78–83.

H. Fukunaga and K. Goda, “Composite Structure of Silicon Carbide Fiber Reinforced Metals,” Bull. JSME, 28 (1985), pp. 1–6.

T.W. Clyne et al., “The Use of ∂-alumina Fibre for Metal-Matrix Composites,” J. Mater. Sci., 10 (1985), pp. 85–96.

H. Kaufmann and A. Mortensen, “Wetting of Saffil™ Alumina Fiber Preforms by Aluminum at 973 K,” Metall. Trans., 23A (1992), pp. 2071–2073.

V.J. Michaud and A. Mortensen, “Infiltration of Fiber Preforms by a Binary Alloy. Part II: Further Theory and Experiments,” Metall. Trans., 23A (1992), pp. 2263–2280.

A. Mortensen and J.A. Cornie, “On the Infiltration of Metal Matrix Composites,” Metall. Trans., 18A (1987), pp. 1160–1163.

A. Mortensen et al., “Infiltration of Fibrous Preforms by a Pure Metal: Part I. Theory,” Metall. Trans., 20A (1989), pp. 2535–2547.

A. Mortensen and V. Michaud, “Infiltration of Fiber Preforms by a Binary Alloy: Part I. Theory,” Metall. Trans., 21A (1990), pp. 205–2072.

A. Mortensen, “Corrigenda and Comments on the Infiltration of Fiber Preforms,” Metall. Trans., 21A (1990), p. 2287.

A. Mortensen and T. Wong, “Infiltration of Fibrous Preforms by a Pure Metal: Part III. Capillary Phenomena,” Metall. Trans., 21A (1990), pp. 2257–2263.

L.J. Masur et al., “Infiltration of Fibrous Preforms by a Pure Metal: Part II. Experiment,” Metall. Trans., 20A (1989), pp. 2549–2557.

P. Jarry et al., “Infiltration of Fiber Preforms by an Alloy Part III: Die Casting Experiments,” Metall. Trans., 23A (1992), pp. 2281–2289.

J.L. Sommer, “Infiltration of Deformable Porous Media” (Ph.D. thesis, MIT, 1992).

A. Mortensen, “Interfacial Phenomena in the Solidification Processing of Metal Matrix Composites,” Mater. Sci. & Eng., A135 (1991), pp. I–II.

R.M. Andrews and A. Mortensen, “Lorentz Force Infiltration of Fibrous Preforms,” Metall. Trans., 22A (1991), pp. 2903–2915.

R.B. Calhoun and A Mortensen, “Infiltration of Fiber Preforms by a Pure Metal Part IV: Morphological Stability of the Remelting Front Separating Fully Liquid from Semisolid Infiltrant,” Metall. Trans., 23A (1992), pp. 2291–2299.

C.N. Cochran and R.C. Ray, “Production of Reinforced Composites,” U.S. patent 3,547,180 (1970).

S.-I. Towata, H. Ikuno, and S.-I. Yamada, “Carbon Fiber and Whisker Reinforced Alumninum Alloys by a Squeeze Casting Process” Sixth International Conference on Composite Materials, ICCM 6, ed. F.L. Matthews et al. (London: Elsevier, 1987), pp. 2.412–2.421.

S.-I. Yamada, S.-I. Towata, and H. Ikuno, “Mechanical Properties of Aluminum Alloys Reinforced with Continuous Fibers and Dispersoids” Advances in Cast Reinforced Metal Composites, ed. S.G. Fishman and A.K. Dhingra (Materials Park, OH: ASM, 1988), pp. 109–114.

H. Ikuno, S.-I. Towata, and S.-I. Yamada, “Thermal Cycling Behavior of Carbon Fiber-Reinforced Al Alloy with SiC Particulates and Whiskers,” J. Jpn. Inst. Met., 53 (1989), pp. 327–332.

S.-I. Towata, S.-I. Yamada, and T. Ohwaki, “Strength and Interfacial Reaction of High Modulus Carbon Fiber-Reinforced Aluminum Alloys,” Trans. Jpn. Inst. Met., 26 (1985), pp. 563–570.

S.-I. Towata and S.-I. Yamada, “Mechanical Properties of Aluminum Alloy Composites with Hybrid Reinforcements of Continuous Fiber and Whisker or Particulate” Composites’ 86: Recent Admnces in lapan and the United States, CCM-III, ed. K. Kawata, S. Umekawa, and A. Kobayashi (Tokyo: Jpn. Soc. Compo Mater., 1986), pp. 497–503.

S.-I. Towata, H. Ikuno, and S.-I. Yamada, “Mechanical Properties of Silicon-Carbide Fiber-Reinforced Aluminum Alloys with Whiskers or Particulates,” J. Jpn. Inst. Met., 51 (1987), pp. 248–255.

C.M. Friend, I. Horsfall, and C.L. Burrows, “The Effect of Particulate: Fibre Ratio on the Properties of Short-Fibre/Particulate Hybrid MMC Produced by Preform Infiltration,” J. Mater. Sci., 26 (1991), pp. 225–231.

T. Itoh, H. Hirai, and R-I. Isomura, “Aluminum Alloy Matrix Composites with Discontinuous Fibers Oriented UniaxiaDy by Electrostatic Method,” J. Jpn Inst. Light Metals, 38 (1988), pp. 620–625.

S.-I. Masuda and T. Itoh, “Electrostatic Means for Fabrication of Fiber-Reinforced Metals,” IEEE Trans. Ind. Applic., 25 (1989), pp. 1989.

Battelle Advanced Materials, “Reticulated-Foam Composite Castings” (Columbus, OH: Battelle, 1990).

T. Fitzgerald and A. Mortensen, work in progress, MIT (1992).

W.E. Curwell and A.J. Shaler, “Method of Forming a Composite by Infiltrating a Porous Prefonn,” U.S. patent 4,033,400 (1977).

F.F. Lange, B.V. Velamakanni,and A.G. Evans, “Method for Processing Metal Reinforced Ceramic Composites” (Paper no. 39-8-88P presented at the 41st Pacific Coast Regional Meeting of the American Ceramic Society, San Francisco, CA, 1988).

D.R. Clarke, “Interpenetrating Phase Composites,” J. Am. Cer. Soc., 75 (1992), pp. 739–759.

L.J. Masur, “Infiltration of Fibrous Preforms by a Pure Metal” (Ph.D. thesis, MIT, 1988).

S. Nourbakhsh, F.L. Liang, and H. Margolin, “An Apparatus for Pressure Casting of Fibre-Reinforced High-Temperature Metal-Matrix Composites,” J. Phys. E: Scientific Instruments, 21 (1988), pp. 895–902.

J. Charbonnier and F. Goliard, “Method and Apparatus for Sand Moulding Composite Articles with a Die Made of Light Alloy and a Fibrous Insert,” U.S. patent 4,889,177 (1989).

M.W. Toaz, “Ceramic-Reinforced Metal Matrix Composites Fabricated by Squeeze Casting.” Advanced Composites, ed. M.W. Liddtke and W.H. Todd (Metals Park, OH: ASM, 1985), pp. 231–237.

M.A.H. Howes, “Ceramic-Reinforced Metal Matrix Composites Fabricated by Squeeze Casting,” Advanced Composites, ed. M.W. Liddtke and W.H. Todd (Metals Park, OH: ASM, 1985), pp. 223–230.

K.U. Kainer and B.L. Mordike, “Herstellung und Eigenschaften von Kurzfaserverstärkten Magnesium-Legierimgen,” Metall, 44 (1990), pp. 438–443.

S.K. Verma and J.L. Dorcie, “Manufacturing of Composites by Squeeze Casting” in Ref. 34, pp. 115–126.

H. Fukunaga, “Squeeze Casting Processes for Fiber Reinforced Metals and their Mechanical Properties,” in Ref. 34, pp. 101–107.

T.W. Oyne and J.F. Mason, “The Squeeze Infiltration Process for Fabrication of Metal-Matrix Composites,” Metall. Trans., 18A (1987), pp. 1519–1530.

K. Suganuma et al., “AA6061 Composite Reinforced with Potassium Titanate Whisker,” J. Mater. Sci. Lett., 8 (1989), pp. 808–810.

K. Suganuma et al., “Aluminium Composites Reinforced with a New Aluminium Borate Whisker,” J. Mater. Sci. Lett., 9 (1990), pp. 633–635.

S. Kohara and N. Muto, “Fabrication of SiC Whisker-Aluminum Composites,” Composites’ 86: Recent Advances in Japan and the United States, ed. K. Kawata, S. Umekawa, and A. Kobayashi (Tokyo: Jpn. Soc. Camp. Mater., 1986), pp. 491–496.

A.A. Das et al., “Solidification under Pressure: Aluminium and Zinc Alloys Containing Discontinuous SiC Fibre,” in Ref. Advances in Cast Reinforced Metal Composites, ed. S.G. Fishman and A.K. Dhingra (Materials Park, OH: ASM, 1988), pp. 139–147.

R.J. Sample, R.B. Bhagat, and M.F. Amateau, “High Pressure Squeeze Casting of Unidirectional Graphite Fiber Reinforced Aluminum Matrix Composites,” in Ref. 34, pp. 179–183.

R.J. Sample, R.B. Bhagat, and M.F. Amateau, “High Pressure Squeeze Casting of Unidirectional Graphite Fiber Reinforced Aluminum Matrix Composites,” J. Compo Mater., 23 (1989), pp. 1021–1028.

C.R. Cook, D.I. Yun, and W.H. Hunt, “System Optimization for Squeeze Cast Composites” in Ref. 34, pp. 195–204.

P. Jarry et al., “Influence of Matrix Solidification during Infiltration on the Structure of a Cast Fibre Reinforced Alloy,” F. Weinberg International Symposium on Solidification Processing, ed. J.E. Lait and I.V. Samarasekera (Hamilton, Canada: Pergamon Press, 1990), pp. 195–204.

F.A Girot et al., “On the Squeeze Casting Conditions of Aluminum Matrix Composite Materials,” J. Reinf. Plastics and Comp., 9 (1990), pp. 456–469.

J. Charbonnier et al., “High Performance Metal-Matrix Components Manufactured by Squeeze-Casting,” in Ref. 34, pp. 127–132.

M.F. Amateau and K.R. Karasek, “Graphite-Metal Matrix Bearings and Methods of Manufacturing,” U.S. patent 4,508,158 (1985).

K. Hashimoto, S. Sekiguchi, and K. Yamada, “Shear Properties of MMC by Torsion Tests,” Interfaces in Metal Ceramic Composites, ed. R. Y. Lin et al. (Warrendale, PA: TMS, 1989), pp. 551–557.

J.G. Banker, “,” SAMPE Quarterly, 5 (1974), pp. 39–46.

S.E. Booth, A.W. Clifford, and N.J. Parratt, “Casting Fibre Reinforced Metals,” U.K. patent GB 2,115,327 A (1983).

R. Asthana and P.K. Rohatgi, “Synthesis of SiC Platelet Reinforced 2014 Al Alloys by a Pressure Infiltration Technique,” J. Mater. Sci. Lett., 10 (1991), pp. 230–234.

J. Yang and D.D.L. Chung, “Casting Particulate and Fibrous Metal-Matrix Composites by Vacuum Infiltration of a Liquid Metal under an Inert Gas Pressure,” J. Mater. 5ci., 24 (1989), pp. 3605–3612.

J.-M. Chiou and D.D.L. Chung, “Characterization of Metal-Matrix Composites Fabricated by Vacuum Infiltration of a Uquid Metal under an Inert Gas Pressure,” Metal & Ceramic Matrix Composites: Processing, Modeling & Mechanical Behavior, ed. R.B. Shagat (Warrendale, PA: TMS, 1990), pp. 107–115.

J.-M. Chiou and D.D.L. Chung, “Cbaracterization of Metal Matrix Composites Fabricated by Vacuum Infiltration of a Liquid Metal under an Inert Cas Pressure,” J. Mater. Sci., 26 (1991), pp. 2583–2589.

S. Nourbakhsh, F.L. Liang, and H. Margolin, “Fabrication of a Ni3Al/Al2O3 Unidirectional Composite by Pressure Casting, Adv. Mater. and Proc., 3(1) (1988), pp. 57–78.

S. Nourbakhsh, H. Margolin, and F.L. Liang. “Microstructural Observations of Pressure Cast Ni3Al/AI2O3 and Ni/Al2O3 Composites,” Metall. Trans., 20A (1989), pp. 2159–2166.

S. Nouroakhsh and H. Margolin, “Fabrication of High Temperature Fiber Reinforced Intermetallic Matrix Composites,” Metal & Ceramic Matrix Composites: Processing, Modeling & Mechanical Behavior, ed. R.B. Bhagat (Warrendale, PA: TMS, 1990), pp. 75–89.

S. Nourbakhsh, H. Margolin, and F.L. Liang, “Fabrication of Continuous ZTA Fiber Reinforced Titanium Aluminide Intermetallic Composite Material by Pressure Casting,” Solidification of Metal Matrix CompoSites, ed. P.K. Rohatgi (Warrendale, PA: TMS, 1990), pp. 103–114.

J.T. Blucher, “Discussion of a Liquid Metal Pressure Infiltration Process to Produce Metal Matrix Composites,” J. Mater. Proc. Techn., 30 (1992), pp. 381–390.

L.J. Masur et al., “Pressure Casting of Fiber-Reinforced Metals,” Sixth International Conference on Composite Materials, ICCM 6, ed. F.L. Matthews (London: Elsevier, 1987), pp. 2.320–2.329.

A.J. Cook, “Method of Vacuum Casting,” U.S. patent 5,111,871 (1992).

A.J. Cook and P.S. Werner, “Pressure Infiltration Casting of Metal Matrix Composites,” Mater. Sci. & Eng., A144 (1991), pp. 189–206.

A. Mortensen, J.A. Cornie, and M.C. Flemings, “Columnar Dendritic Solidification in a Metal-Matrix Composite,” Metall. Trans., 19A (1988), pp. 709–721.

E. Klier, “Fabrication of Cast Particulate Reinforced Metals via Pressure Infiltration” (M.Sc. thesis, MIT, 1988).

E.M. Klier et al., “Fabrication of Cast Partide-Reinforced Metals via Pressure Infiltration,” J. Mater. Sci., 26 (1991), pp. 2519–2526.

E. Savrun and A. Grenni, “Liquid Infiltration of Metal Matrix Composites,” Innovations in Materials and Applialtion in the Transporation Industry ATA-MAT 89 (Turin, Italy: A.T.d.a.C.N.R., Torino Espozioni, C.so Massimo d’ Azeglio, 1989), pp. 601–611.

J.A. Isaacs et al., “Chemical Stability of Zirconia-Stabilized Alumina Fibers During Pressure Infiltration by Aluminum,” Metall. Trans., 22A (1991), pp. 2855–2862.

A.J. Cook, “Top Fill Casting.” U.S. patent 5,1 11,870(1992).

K. Atsushei, “Fibre Reinforced Metal Artide Manufactured by Placing Fibre Bundle in Mould, Pouring Molten Metal into Cavity, Pressing and Solidifying.” Japan patent 60-29433 (1985).

A.W. Clifford and W.J. Cook, “Production of Fibre Reinforced Metal Sections,” Eur. patent appl. 0,304,167 (1989).

Y. Tsunekawa et al., “Centrifugally Cast Aluminium Matrix Composites Containing Segregated Alumina Fibres,” J. Mater. Sci. Lett., 7 (1988), pp. 830–832.

R.M. Andrews and A. Mortensen, “Lorentz Force Driven Infiltration by Aluminum,”Mater. Sci. & Eng., A144 (1991), pp. 165–168.

H. Fukunaga, X. Wang. and Y. Aramaki, “Preparation of Intermetallic Compound Matrix Composites by Reaction Squeeze Casting,” J. Mater. Sci. Lett., 9 (1990), pp. 23–25.

D.C. Dun, J.L. Sommer, and A Mortensen, “Reactive Infiltration of Nickel Preforms with Molten Aluminum” (Paper presented at Materials Week, Chicago, IL, 1–5 Navember 1992).

A. Mortensen, “A Review of the Fracture Toughness of Partide Reinforced Aluminum Alloys,” Fabrication of Particulate Reinforced Metal Composites (Materials Park, OH: ASM, 1990), pp. 217–233.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mortensen, A., Michaud, V.J. & Flemings, M.C. Pressure-infiltration processing of reinforced aluminum. JOM 45, 36–43 (1993). https://doi.org/10.1007/BF03223364

Issue Date:

DOI: https://doi.org/10.1007/BF03223364