Abstract

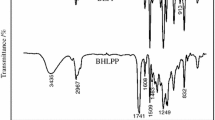

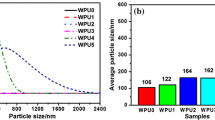

A series of crosslinkable, waterborne polyurethanes (I-WBPUs) were prepared by in-situ polymerization using isophorone diisocyanate (IPDI)/poly(tetramethylene oxide) glycol (PTMG,M n =2,000)/ dimethylol propionic acid (DMPA)/ethylene diamine (EDA)/triethylamine (TEA)/aminoplast [hexakis(methoxymethyl)melamine (HMMM)] as a crosslinking agent. Typical crosslinkable, waterborne polyurethanes (B-WBPUs) blended from WBPU dispersion and aqueous HMMM solution was also prepared to compare with the I-WBPUs. The crosslinking reaction between WBPU and HMMM was verified using FTIR and XPS analysis. The effect of the HMMM contents on the dynamic mechanical thermal, thermal, mechanical, and adhesion properties of the I-WBPU and B-WBPU films were investigated. The storage modulus (E′), glass transition temperatures of the soft segment (T gs ) and the amorphous regions of higher order (T gh ), melting temperature (T m ), integral procedural decomposition temperature (IPDT), residual weight,T10% andT50% (the temperature where 10 and 50% weight loss occurred), tensile strength, initial modulus, hardness, and adhesive strength of both I-WBPU and B-WBPU systems increased with increasing HMMM content. However, these properties of the I-WBPU system were higher than those of the B-WBPU system at the same HMMM content. These results confirmed the in-situ polymerization used in this study to be a more effective method to improve the properties of the WBPU materials compared to the simple blending process.

Similar content being viewed by others

References

I. Dimitrievski and T. Malavasic,Prog. Org. Coat.,32, 51 (1995).

J. Koleske,ASTM Standardization News, October, 24 (1995).

U. Santer,J. Prog. Org. Coat.,12, 309 (1994).

K. Mequanint and R. Sanderson,Polymer,43, 5341 (2002).

S. H. Kang, D. C. Ku, J. H. Lim, Y. K. Yang, N. S. Kwak, and T. S. Hwang,Macromol. Res.,13, 212 (2005).

K. Mequanint and R. Sanderson,Polymer,44, 2631 (2003).

W. Morgans, inOutlines of Paint Technology, Halsted Press, New York, 1990, Chap. 11.

V. Mirgel and M. Sonntag,Eur. Coatings J.,10, 690 (1994).

D. Quan, E. C. Dickey, R. Andrews, and T. Rantell,Appl. Phys. Lett.,76, 2868 (2000).

M. Jung and J. W. Cho,Journal of the Korean Fiber Society,41, 73 (2004).

Y. S. Kwak and H. D. Kim,Fibers and Polymers,3, 153 (2002).

W. Otterbein and G. Pollano, Modern Paint and Coatings, March, 32 (1995).

A. Marquez, J. Uribe, and T. Cruz,J. Appl. Polym. Sci.,66, 2221 (1997).

B. Eling, inPolyurethane Technology & Applications, S. Lee, Ed., Huntsman International, Everberg, Belgium, 2002, Chap. 25, pp 379–383.

D. Hanquaer, Jr. (Textron Inc.), US Patent 4, 203, 883 (1998).

H. Jotischky,Eur. Coatings J.,10, 696 (1995).

C. Schoff,ASTM Standardization News, October, 24 (1995).

T. Triplett,Industrial Paint and Powder,10, 28 (1995).

R. B. Orr and L. Chicsky, Jr. (Seton Co.), US Patent 4, 690, 953 (1987).

F. A. Wickert (Glidden Co.), US Patent 5, 066, 705 (1991).

Y. Tamaki and S. Ueda (Dainippon Ink & Chemicals), Jpn. Patent 5, 202, 162 (1993).

W. Thoma, K. Nachtkamp, W. Schroeer, and R. Langel (Bayer), Ger. Offen, DE 3313237 (1984).

K. Matsuda, H. Ohmura, and T. Sakai (Kao Soap), Ger. Offen, DE 2632544 (1997).

R. Kennedy,Eur. Coatings J.,10, 670 (1994).

H. V. Dijk, inWaterborne & Solvent Based Surface Coating Resins and Their Applications, SITA Technology Ltd, London, U. K., 1999, Vol. 2, pp 8–45.

R. Barrett, inWaterborne Coatings and Additives, D. Karsa and W. Davies, Eds., The Royal Society of Chemistry, Cambridge, UK, 1995, pp 85–104.

W. J. Blank and V. J. Tramontano,Prog. Org. Coat.,27, 11 (1996).

D. J. David and H. B. Staley, “Analytical Chemistry of Polyurethanes”, High Polymer Series, Wiley-Interscience, New York, 1969, Vol. 16, Part 3.

W. Chen, K. C. Krisch, D. J. Kenney, and S. J. M. S. Wong,Polymer,29, 567 (1992).

Y. S. Kwak, E. Y. Kim, H. D. Kim, and J. B. Lee,Colloid. Polym. Sci.,283, 880 (2005).

C. D. Doyle,Anal. Chem.,33, 77 (1961).

H. Hiura, T. W. Ebbesen, K. Takagi, and H. Takahashi,Chem. Phys. Lett.,202, 509 (1993).

S. Subramani, J. M. Lee, and J. H. Kim,Macromol. Res.,13, 418 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwon, J.Y., Kim, H.D. Preparation and properties of crosslinkable waterborne polyurethanes containing aminoplast(I). Macromol. Res. 14, 373–382 (2006). https://doi.org/10.1007/BF03219097

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03219097